Prefabricated building connection assembly

A technology of connecting components and assembling, which is applied in the direction of building components, buildings, building structures, etc. It can solve the problems of inconvenient adjustment, external movement of external hanging panels, and insufficient connection effect, etc., to achieve enhanced stability, convenient disassembly and recovery, and improved repetition. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

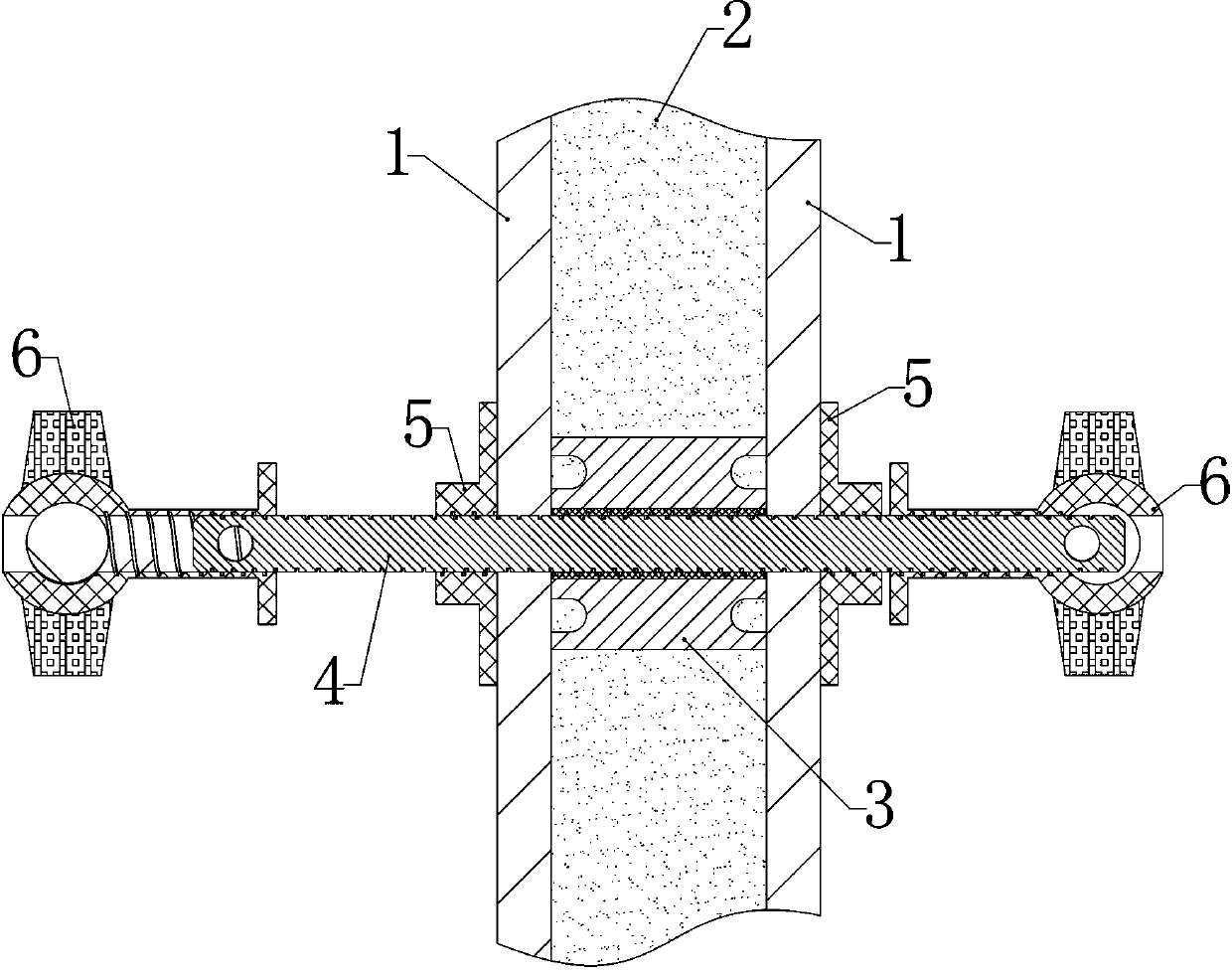

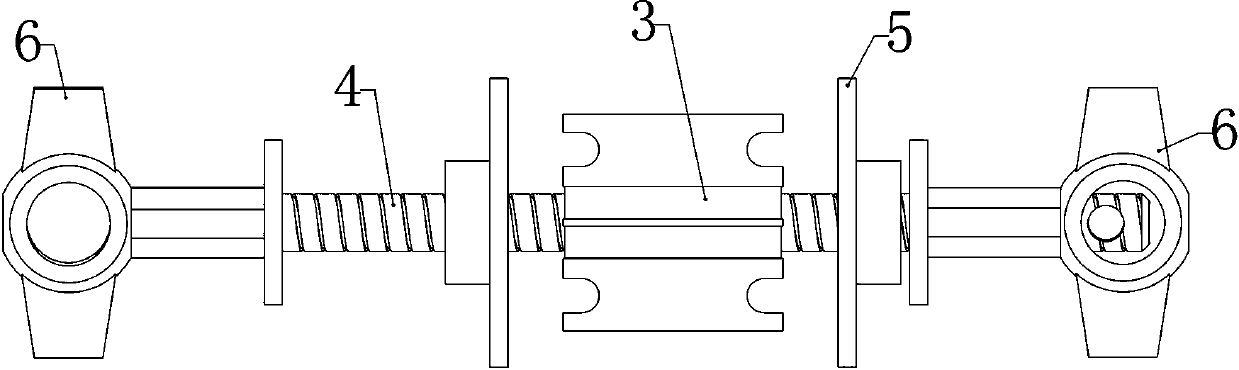

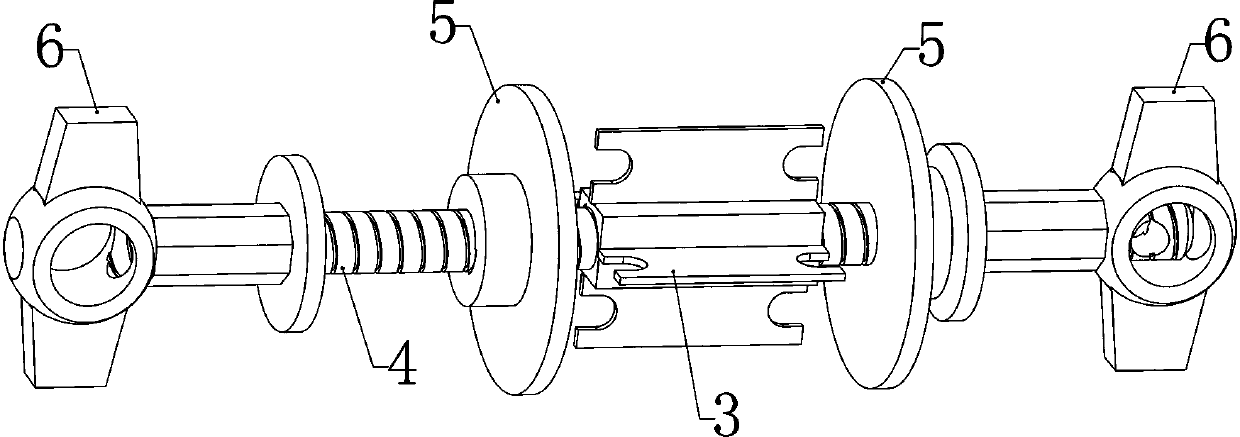

[0027] Such as Figure 1-8 As shown in , a prefabricated building connection assembly includes an outer casing 3 arranged inside the cast-in-place concrete layer 2 between two prefabricated formworks 1, and the two ends of the outer casing 3 are respectively pressed against the corresponding prefabricated formwork On the inner side wall of the formwork 1, a tension screw 4 is co-located in the outer sleeve 3, and both ends of the tension screw 4 move through the assembled formwork 1 on the corresponding side, and on the outside of each assembled formwork 1 A T-shaped helical tube 5 is respectively screwed together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com