Intelligent construction system of large-diameter deep mixing composite pile and use method of intelligent construction system

A deep mixing and composite pile technology, applied in sheet pile wall, foundation structure engineering, soil protection and other directions, can solve problems such as difficult control of construction errors, wear of drill bits, affecting construction progress, etc., and achieve reliable data guidance, data visualization, Parameter adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

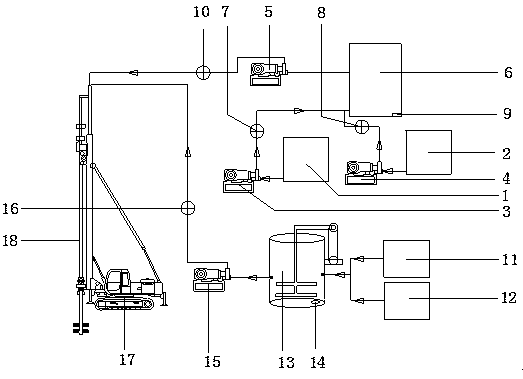

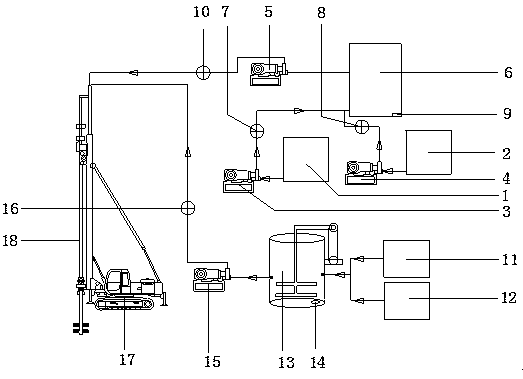

[0035] Such as figure 1As shown, the intelligent construction system of large-diameter deep-layer mixing composite piles is characterized in that it includes a surfactant processing module, a curing agent processing module, a sensor integration module, a signal integration and transmission module, a data processing and storage module, and a display and control module. , drilling rig 17; the surfactant processing module is connected to the drilling rig 17 through a high-pressure rubber hose; the curing agent processing module is connected to the drilling rig 17 through a high-pressure rubber hose; the sensor integration module is arranged between the power unit of the drilling rig 17 and the drill rod 18 Between, the sensor integration module and the drilling rig 17 are connected through a flange; the signal integration and transmission module respectively transmits data with the surfactant processing module, the curing agent processing module, the sensor integration module, and...

Embodiment 2

[0047] On the basis of the above-mentioned embodiments, an equipment operation test is carried out on an outdoor field. The diameter of the test pile is 1.5m, and the depth is 15m. The application method of the intelligent construction system of the large-diameter deep-layer mixing composite pile provided by the present invention is used to test the operation effect of the intelligent equipment. Among them, the specific technologies are as follows:

[0048] Using the intelligent construction system of large-diameter deep-layer mixing composite piles, when the data processing and storage module receives the data from the signal integration and transmission module, the system is controlled according to the following method:

[0049] Step 1: Set an optimal torque range [T1, T2] under different soil properties and different soil depth conditions, set the maximum flow rate of surfactant injection as Qmax, and the maximum concentration of surfactant as Wmax;

[0050] Step 2: During...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com