Degreasing agent for cleaning steel plate surface

A degreaser and steel plate technology, applied in the field of detergent compositions, can solve problems such as affecting product quality and unclean surface cleaning of steel plates, and achieve the effects of maintaining stable chemical properties, excellent decontamination ability, and easy wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0014] The preparation process of the degreasing agent used to clean the surface of the steel plate is as follows: first add 56-83% deionized water and 4-10% modified sodium disilicate to the container, after stirring evenly, add 8-15% potassium hydroxide , after the potassium hydroxide is fully dissolved, add 2-8% tetrasodium edetate, and finally add 2-6% dodecyl glucoside-tetradecyl glucoside and 1-6% methacryl alcohol polyoxyethylene ether 5%, after being stirred evenly, a degreasing agent for cleaning the surface of steel plates is obtained.

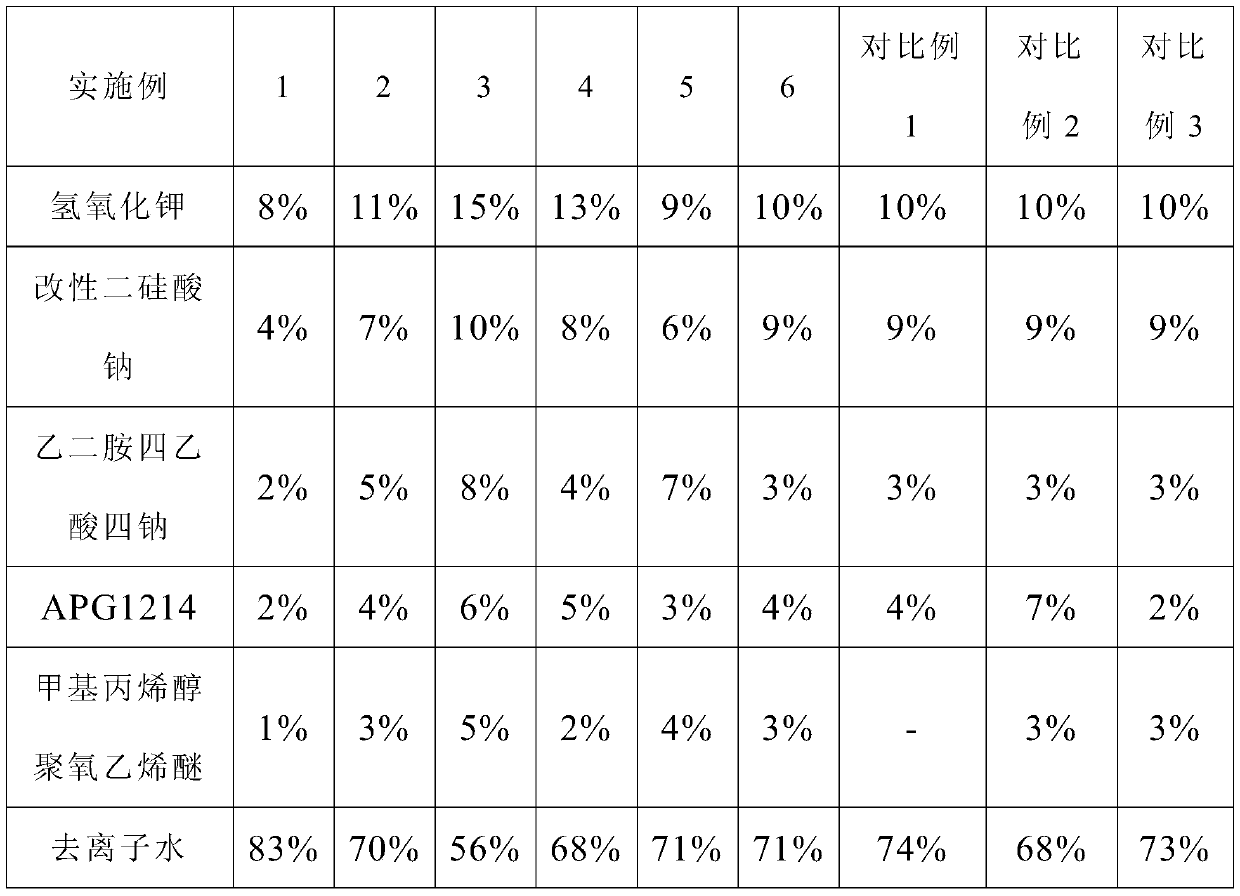

[0015] The components of the degreasing agent used to clean the surface of the steel plate and their weight percentages are shown in Table 1 in Examples 1 to 6:

[0016] Table 1

[0017]

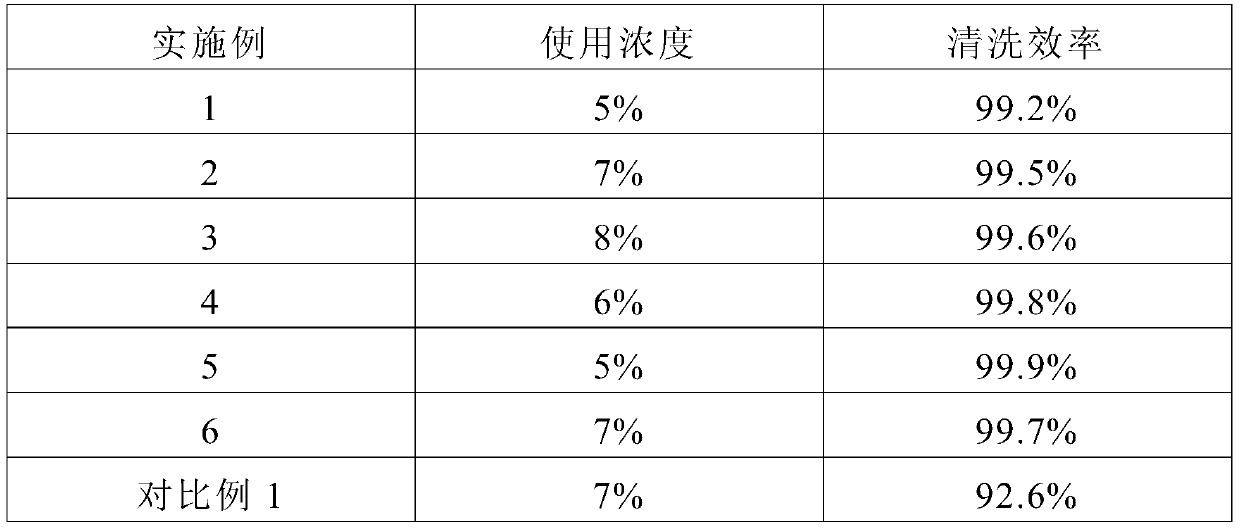

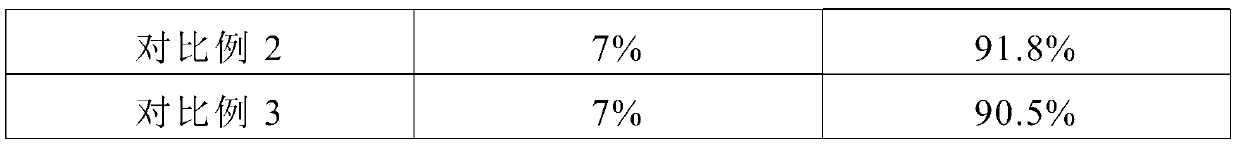

[0018] Embodiment 1~6 obtains the cleaning effect of the degreasing agent used for cleaning the steel plate surface in Table 2:

[0019] Table 2

[0020]

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com