Transfer mechanism

A transfer mechanism and substrate technology, applied in the direction of motor vehicles, space navigation equipment, space navigation equipment, etc., can solve the problems that restrict the engineering development of satellite on-orbit maintenance technology, reduce the control precision requirements, improve the installation precision, Effect of increasing capture margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will facilitate further understanding of the present invention in any form of techniques, but will not limit the invention in any form. It should be noted that several variations and improvements can also be made without departing from the concept of the present invention. These are all of the scope of protection of the present invention.

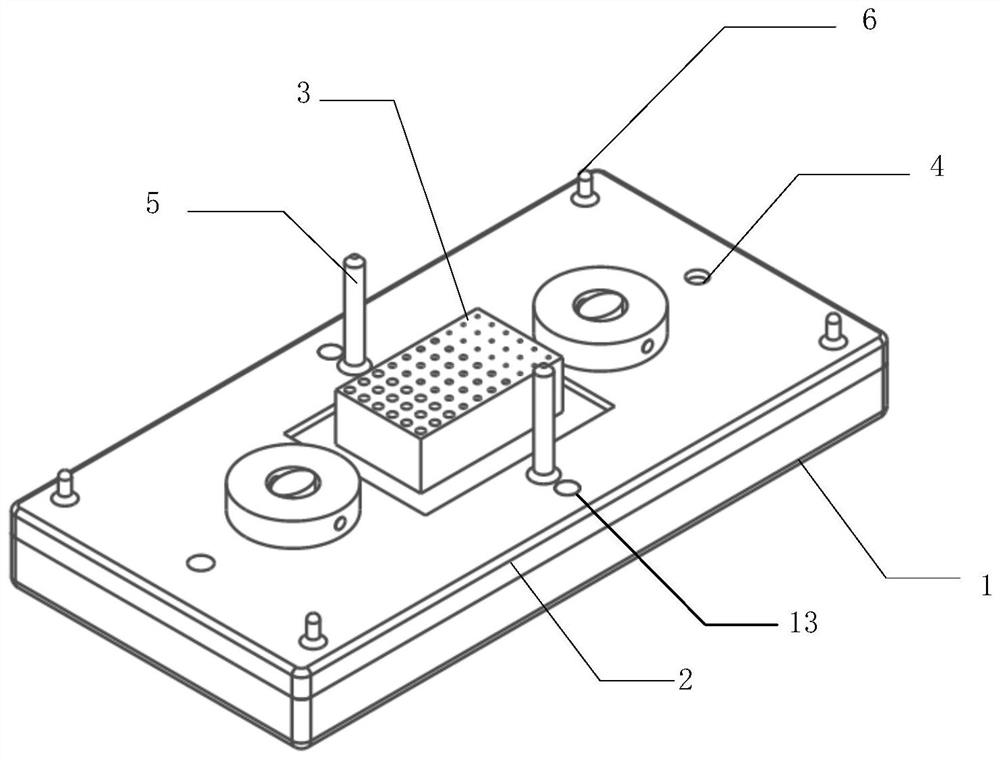

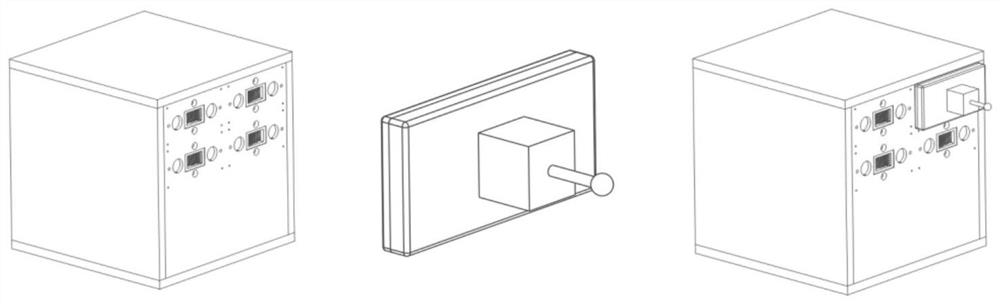

[0041] Such as Figure 1 ~ 5 As shown, the present invention provides an adapter mechanism for a stand-alone module in the rail replacement, including housing 1 and substrate 2. Explosion bolt hole 13, the explosion bolt hole 13 is used to mount the explosion bolt; the electric bolt hole 4 is used to achieve the first locking of the active locking electric bolt matching on the platform; crude position guide 5, coarse position guide The guide 5 guides the thick alignment in the operation of the robot arm; the finite posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com