Steel wire rope twist direction climbing robot

A wire rope and robot technology, applied in the field of robots, can solve the problems of unstable movement and wear on the surface of the wheel body, and achieve the effects of wide range of use, stable movement, high movement efficiency and movement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

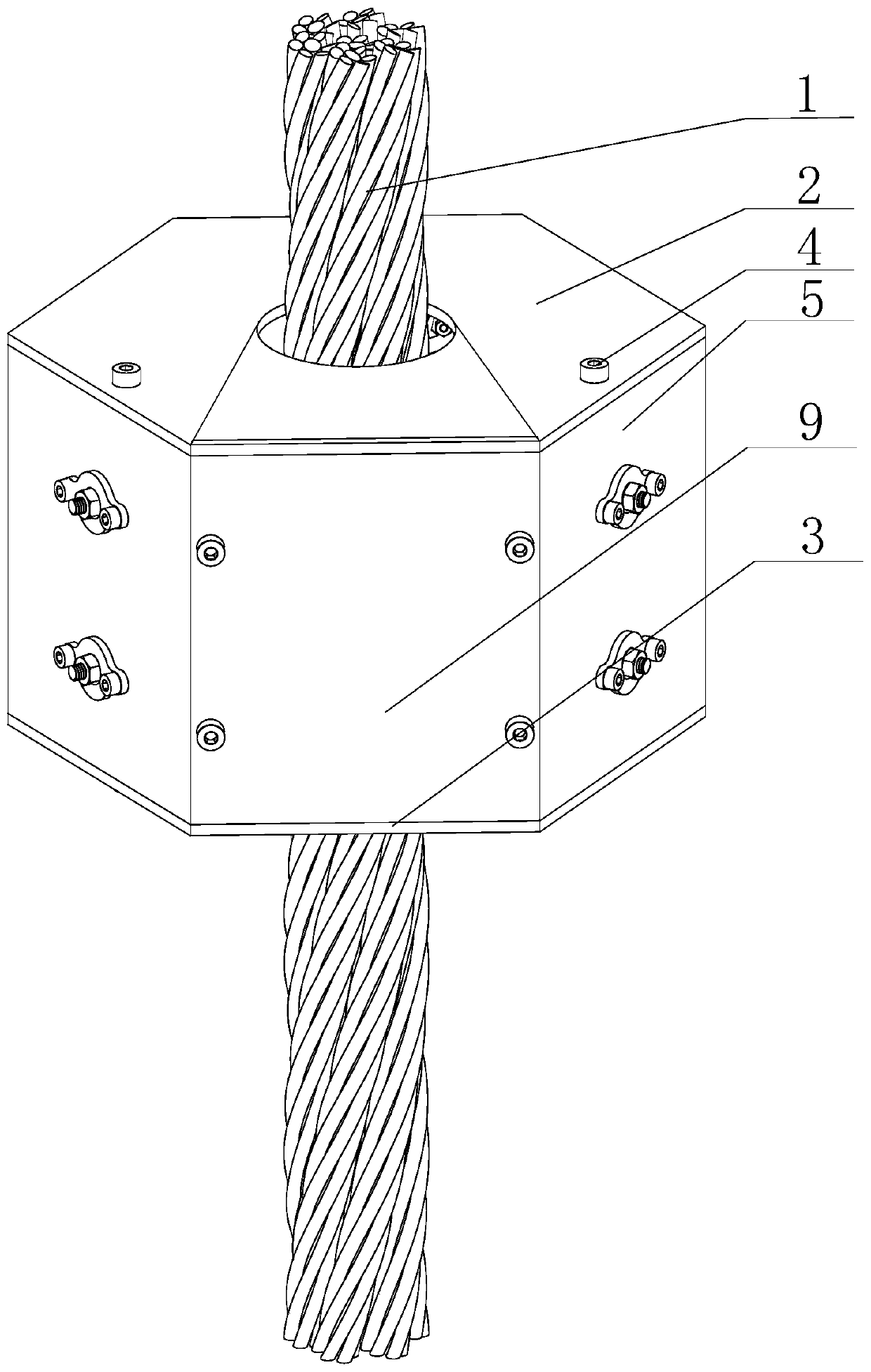

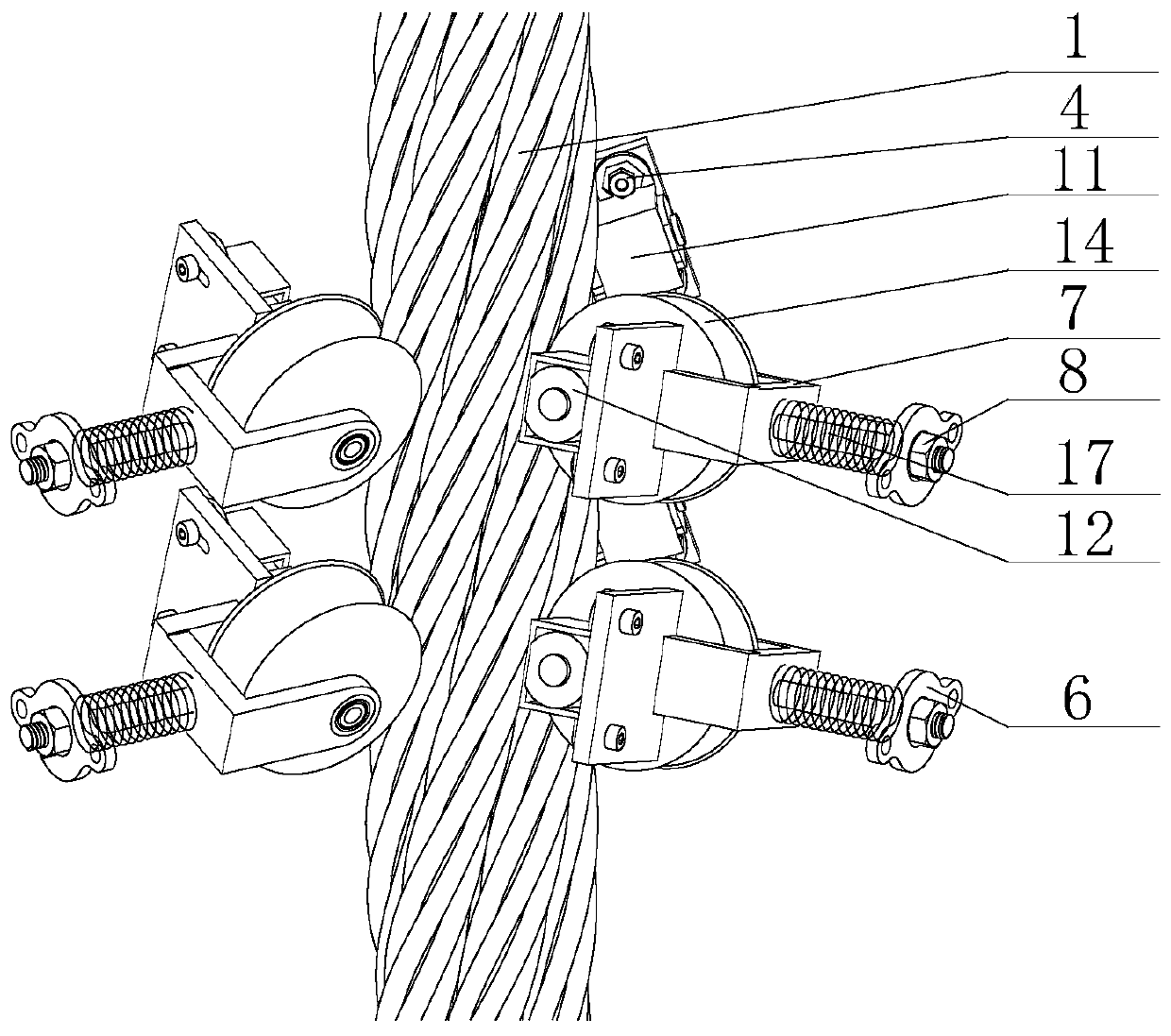

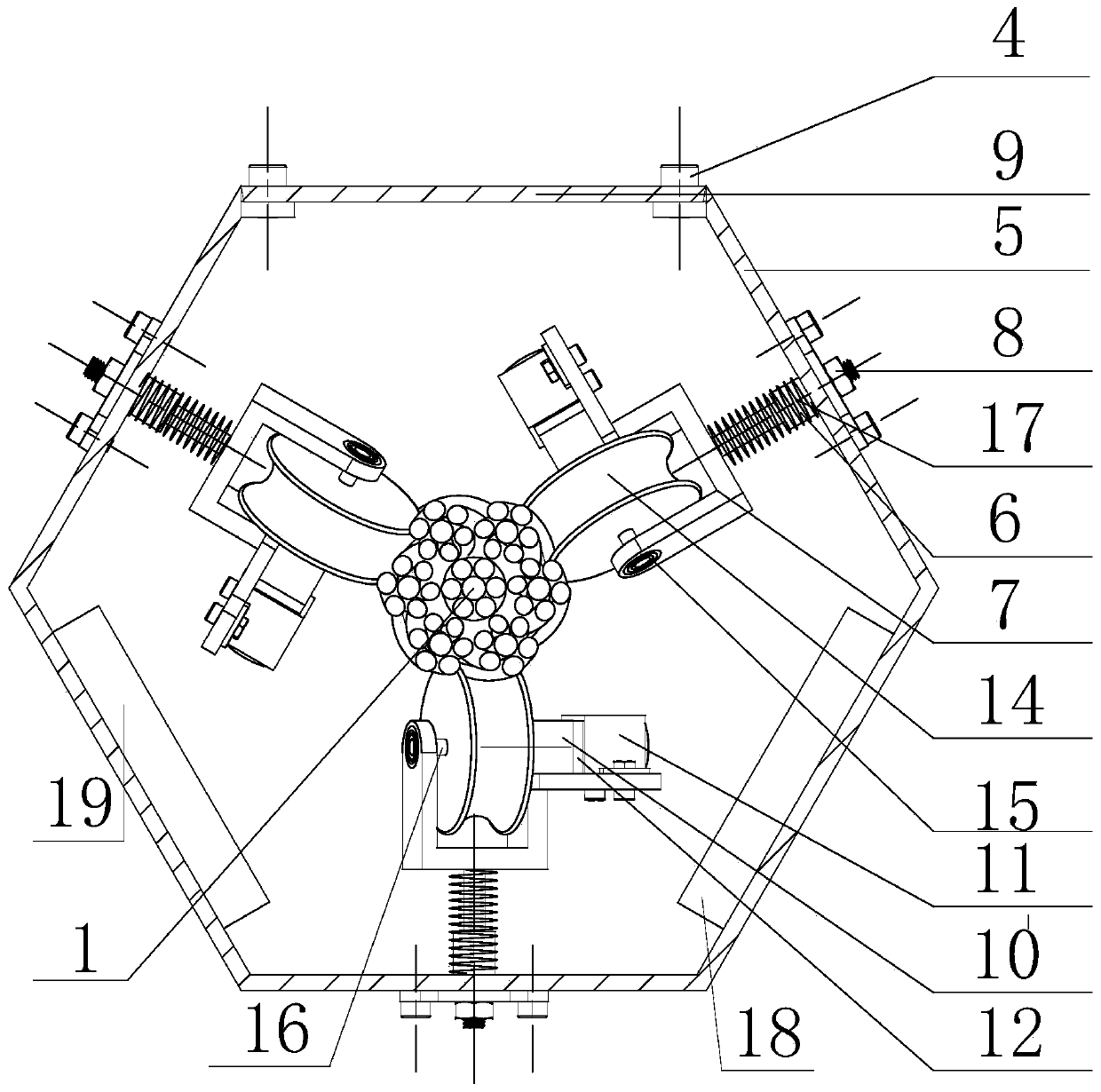

[0032] Such as figure 1 and 5 As shown, the steel wire rope twisting climbing robot of the present invention includes a plurality of modules, and the steel wire rope 1 is formed by helically twisting multiple strands of steel wires, and the number of modules is determined according to the weight of the load to be carried. Each module includes explosion-proof housing, tensioning mechanism, driving mechanism, roller mechanism, power supply module and communication control device. The modules are connected by bolts through the bolt holes when the platform is installed, and the number of modules is set according to the weight of the load. Each module supplies energy independently, and the speed of the modules is controlled by the P1D controller. The explosion-proof housing includes an upper loading platform 2 , a lower loading platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com