Mounting method for embedding magnetic steel into vehicle, and telescopic sun-proof and dust-proof vehicle cover

An installation method, vehicle technology, applied in vehicle parts, transportation and packaging, removable outer sheath, etc., can solve the problems of no breakthrough in the field of installation technology, no ideal installation solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

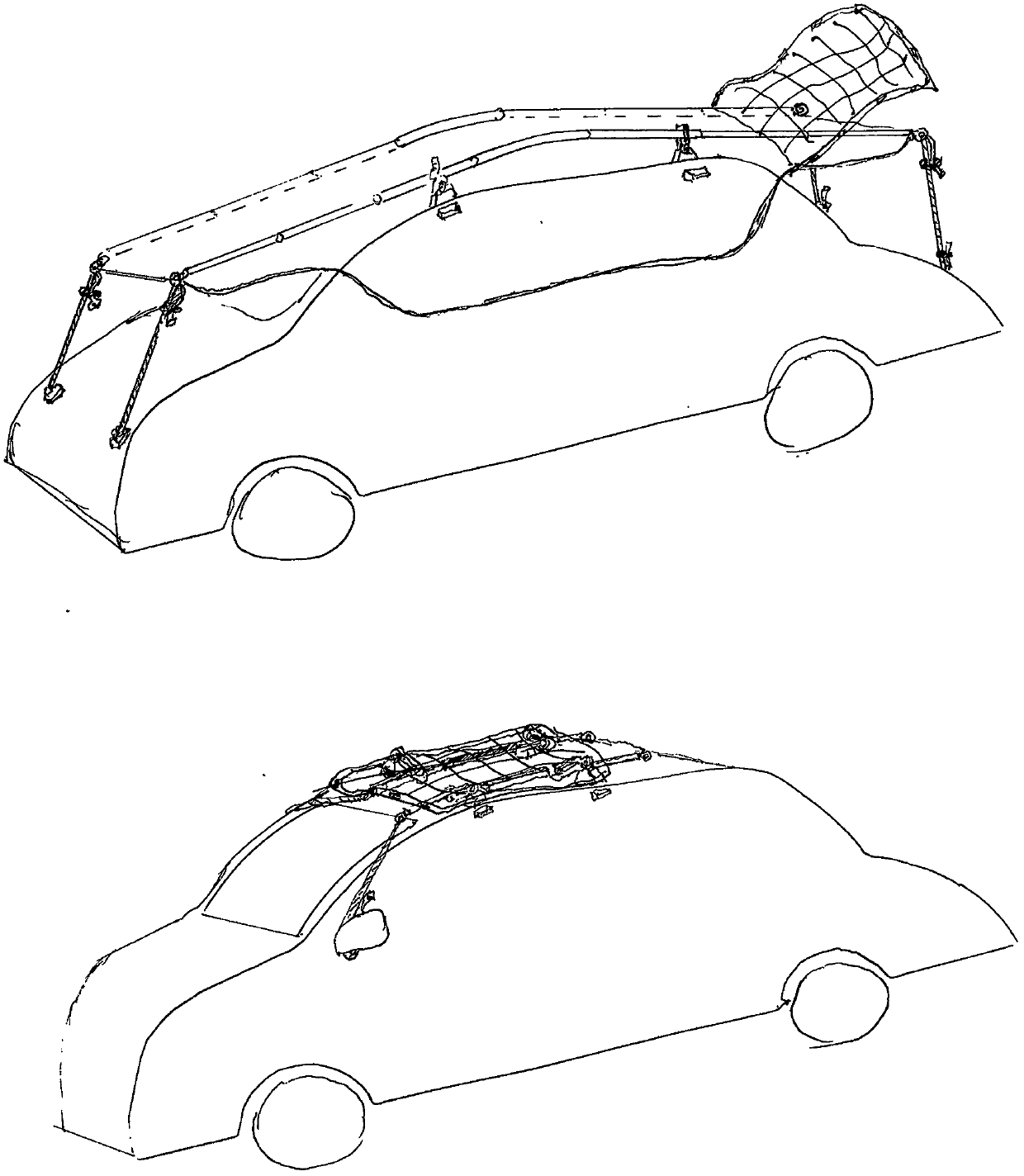

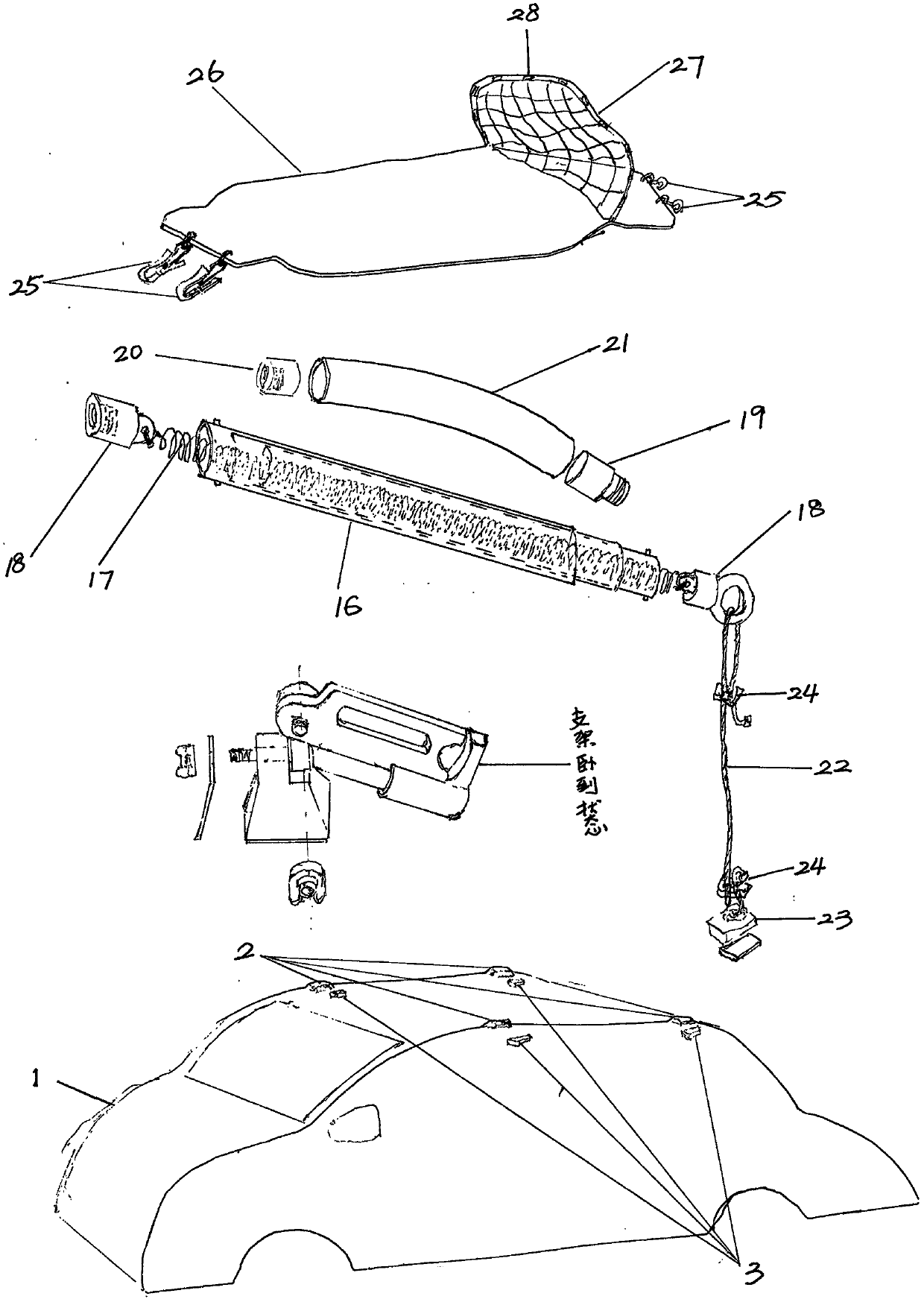

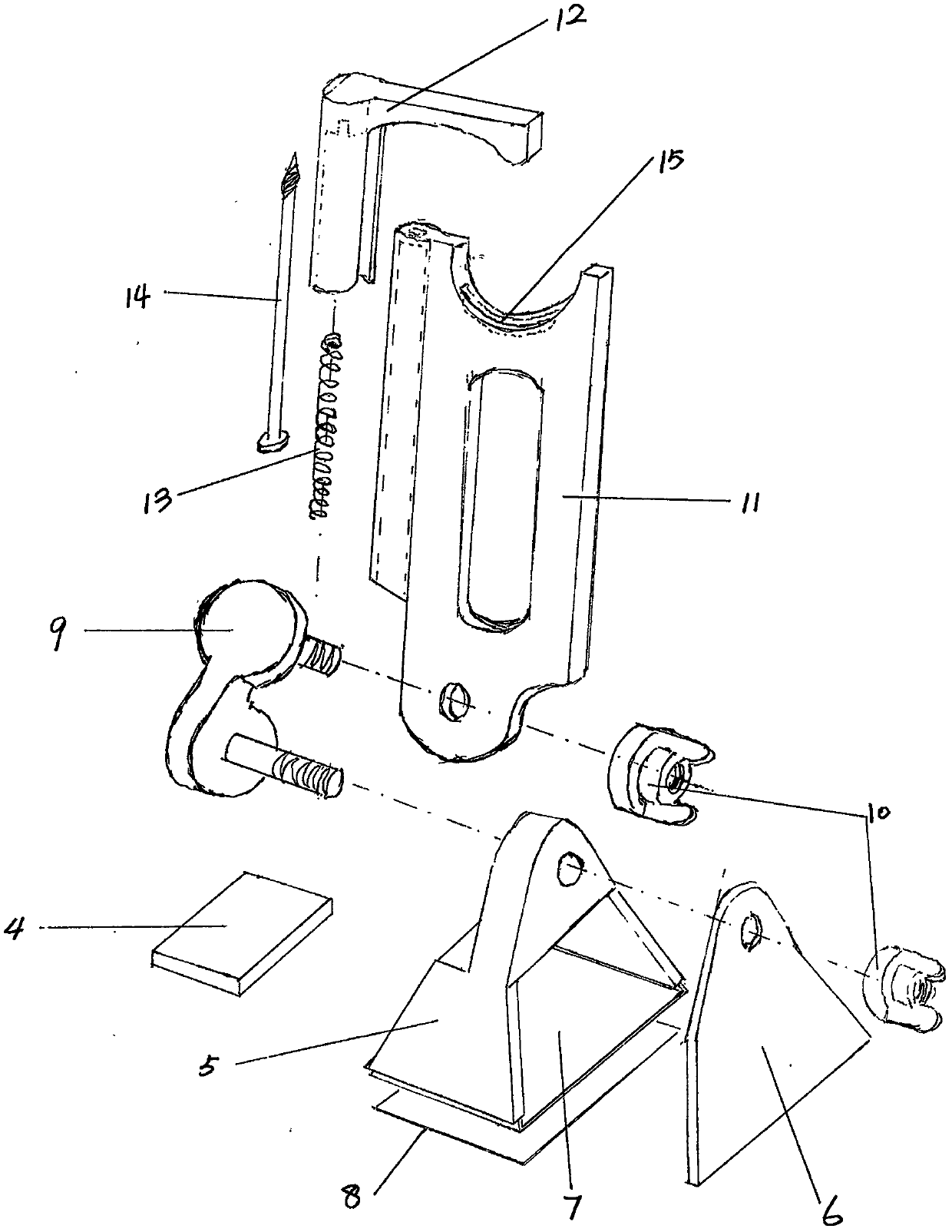

[0007] as attached figure 2 image 3 As shown, first, during the production process of the vehicle 1, a press is used in advance to press out the top protruding point 2 of the size of the magnetic steel 3 at the corresponding position inside the roof iron structure (take the symmetrical positions of the four corners of the roof as an example) and embed it. A piece of magnetic steel 3 is marked with four protruding points 2 of the roof, and telescopic tube supports are placed at the protruding points 2 positions of the outer top of the vehicle 1 (the telescopic tube supports mainly include lower brackets 5, cross connections 9, and lower brackets 5. Adjust polarity magnetic steel 4, upper bracket 11, and upper bracket buckle 12), the lower bracket 5 has a space to put the lower bracket into the adjustable polarity magnetic steel 4, if the vehicle is embedded with magnetic steel 3, the lower bracket of the N pole can be adjusted When the polarity magnetic steel 4 is put in, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com