Manufacturing method and system of polyurethane insulation box for liquefied natural gas ship

A technology for liquefied natural gas and a manufacturing method, which is applied in the field of manufacturing method and manufacturing system of liquefied natural gas marine polyurethane insulating box, can solve the problems of quality monitoring and traceability defects, uneven stress on plywood, poor flexibility, etc. It is difficult to effectively control the accuracy, the assembly quality is reliably controlled, and the equipment investment and the effect are reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

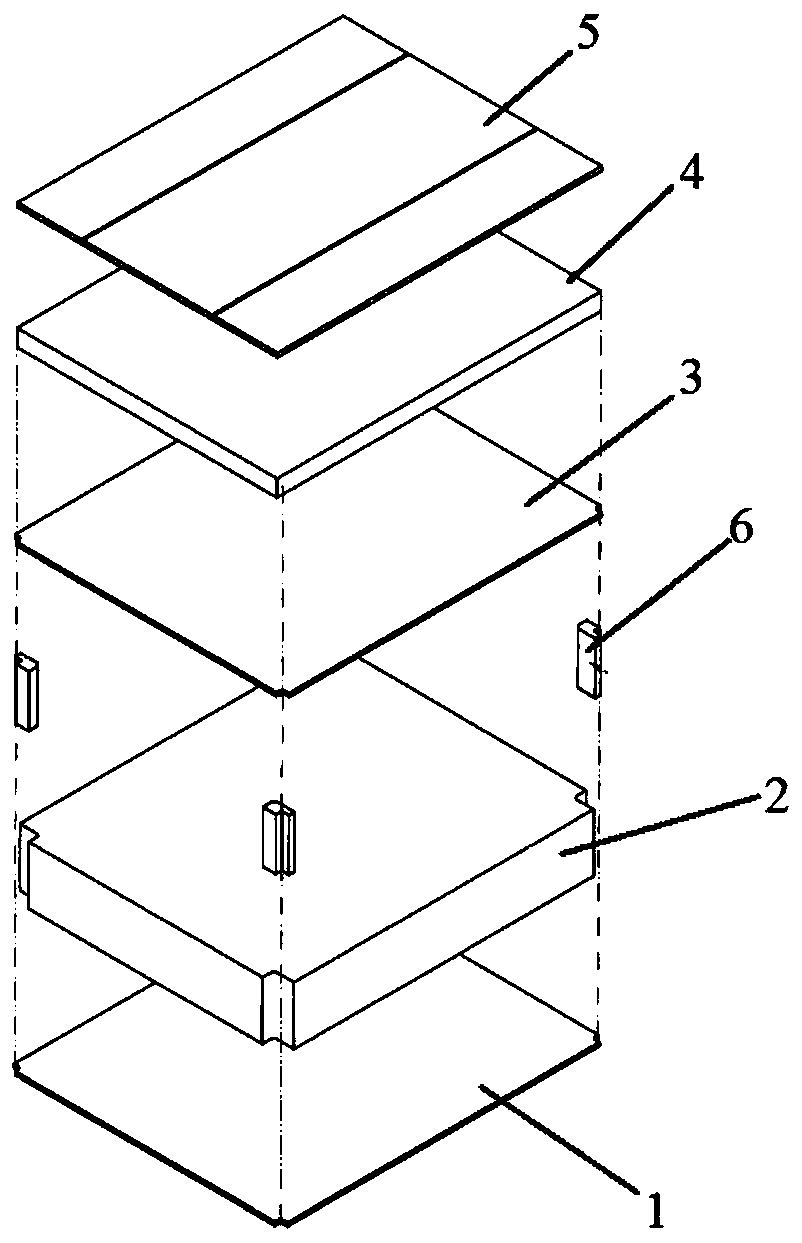

[0077] Such as figure 1 As shown, the L03 type insulating box (K1) includes bottom plywood 1, bottom polyurethane board 2, middle plywood 3, top polyurethane board 4, top plywood 5 and wooden plywood 6.

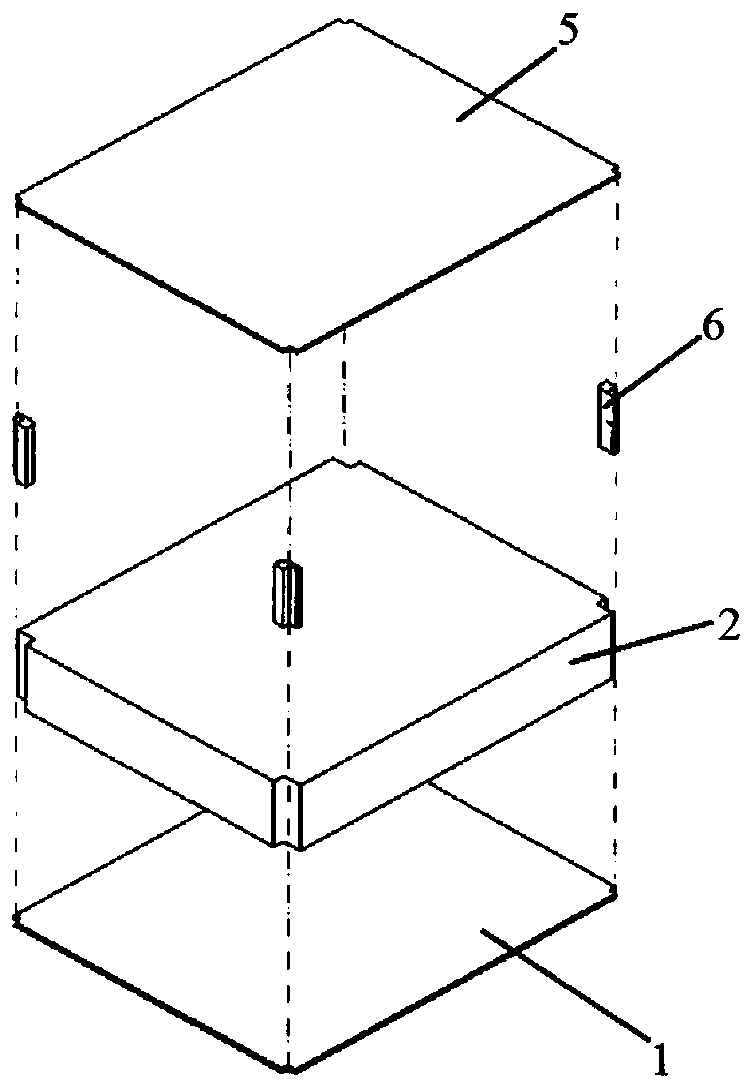

[0078] Such as figure 2 As shown, the L03+ type insulating box (K2, K5) includes a bottom plywood 1, a bottom polyurethane board 2, a top plywood 5 and a wooden plywood 6.

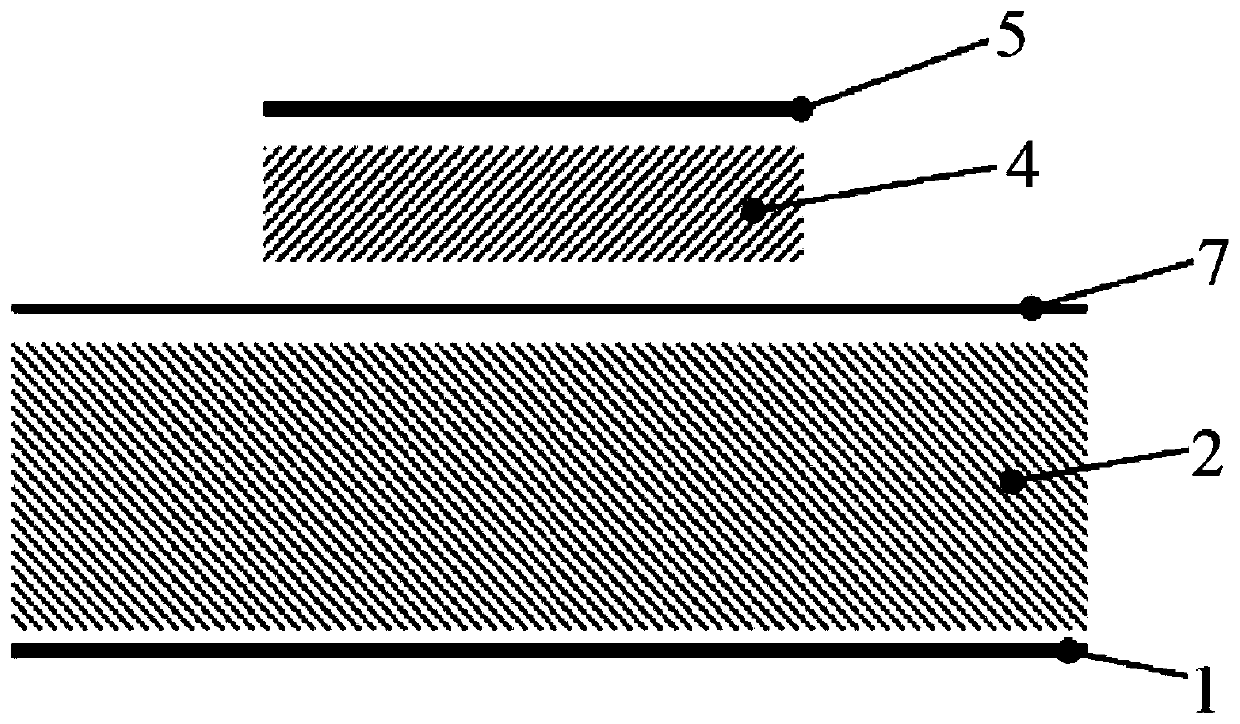

[0079] Such as image 3 As shown, the MARK III insulation box includes a bottom plywood 1 , a bottom polyurethane board 2 , and a hard three-in-one sheet 7 .

[0080] In this embodiment, an intelligent manufacturing method and flexible production system suitable for multi-series, multi-model, and large-size polyurethane insulating boxes for LNG ships are designed, and the functional blocks are set according to the attributes of the processing process by taking advantage of the high efficiency of automation equipment , each station in the block is connected by an automatic logistics conveyor line, and ...

Embodiment 2

[0236] A method for manufacturing a polyurethane insulating box for liquefied natural gas ships, the method includes a glued assembly stage, a leveling output stage, a CNC processing stage, and a packaging stage, and the glued assembly stage includes a general glued assembly process, a pressing process and an aging process, in,

[0237] In the glue joint assembly stage, the overall assembly of the polyurethane insulation box is carried out;

[0238] The general adhesive bonding assembly process is used to assemble the various parts of the polyurethane insulation box;

[0239] The pressing process is to press the assembled polyurethane insulation box;

[0240] Aging process, aging curing of the laminated polyurethane insulation box;

[0241] In the leveling output stage, the upper and lower surfaces of the polyurethane insulation box are polished, and the overall height is corrected;

[0242] In the CNC processing stage, the shape of the polyurethane insulation box is proces...

Embodiment 3

[0277] A method for manufacturing a polyurethane insulating box for liquefied natural gas ships, the method includes a glued assembly stage, a leveling output stage, a CNC processing stage, and a packaging stage, and the glued assembly stage includes a general glued assembly process, a pressing process and an aging process, in,

[0278] In the glue joint assembly stage, the overall assembly of the polyurethane insulation box is carried out;

[0279] The general adhesive bonding assembly process is used to assemble the various parts of the polyurethane insulation box;

[0280] The pressing process is to press the assembled polyurethane insulation box;

[0281] Aging process, aging curing of the laminated polyurethane insulation box;

[0282]In the leveling output stage, the upper and lower surfaces of the polyurethane insulation box are polished, and the overall height is corrected;

[0283] In the CNC processing stage, the shape of the polyurethane insulation box is process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com