Mixing and separation system and method based on fluid enhancement

A separation system and forced mixing technology, applied in the direction of solid separation, fluid mixer, chemical instruments and methods, etc., to achieve the effect of improving hydrophobicity, improving mixing and separating efficiency and ability, and improving mineralization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

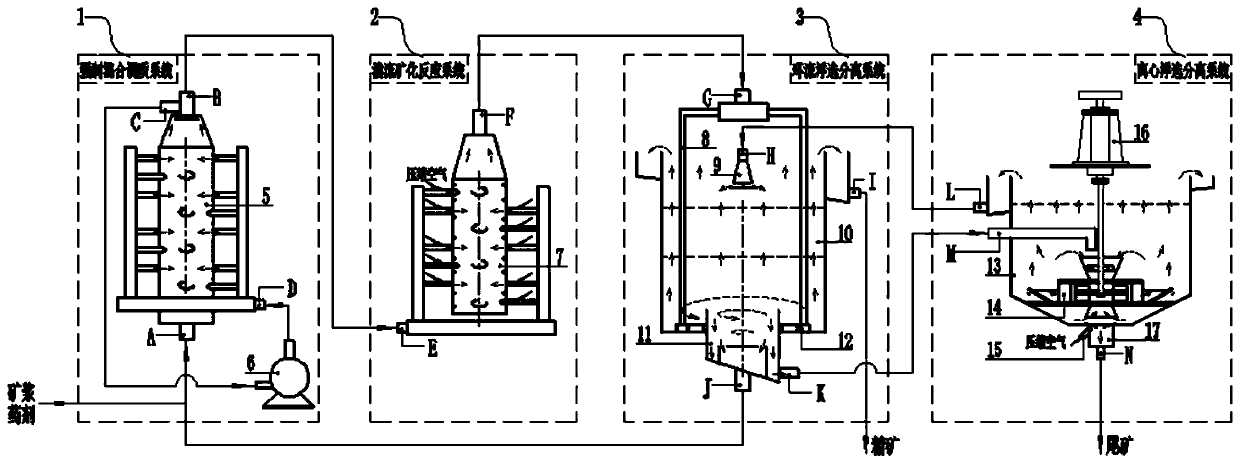

[0027] Such as figure 1 As shown, the mixed separation system based on fluid intensification of the present invention includes a forced mixing and conditioning system 1, a turbulent mineralization reaction system 2, a circulation flotation separation system 3 and a centrifugal flotation separation system 4 connected by pipelines, wherein the forced The outlet C of the circulating pulp of the mixing and tempering system 1 is connected to the inlet D of the distribution tank of the forced mixing conditioner through the circulation pump 6, and the outlet B of the quenched and tempered pulp is connected to the turbulent mineralization reactor of the turbulent mineralization reaction system 2 through the pipeline. The feed port E is connected, the discharge port F of the turbulent mineralization reactor of the turbulent mineralization reaction sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com