Oil-submerged pump sand-blocking-type suction inlet

A suction port and submersible pump technology, which is applied to pumps, pump components, non-variable pumps, etc., can solve the problems of reducing the service life of the unit, wearing equipment and pipelines, and suction port blockage, so as to avoid serious wear and improve The effect of sand resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

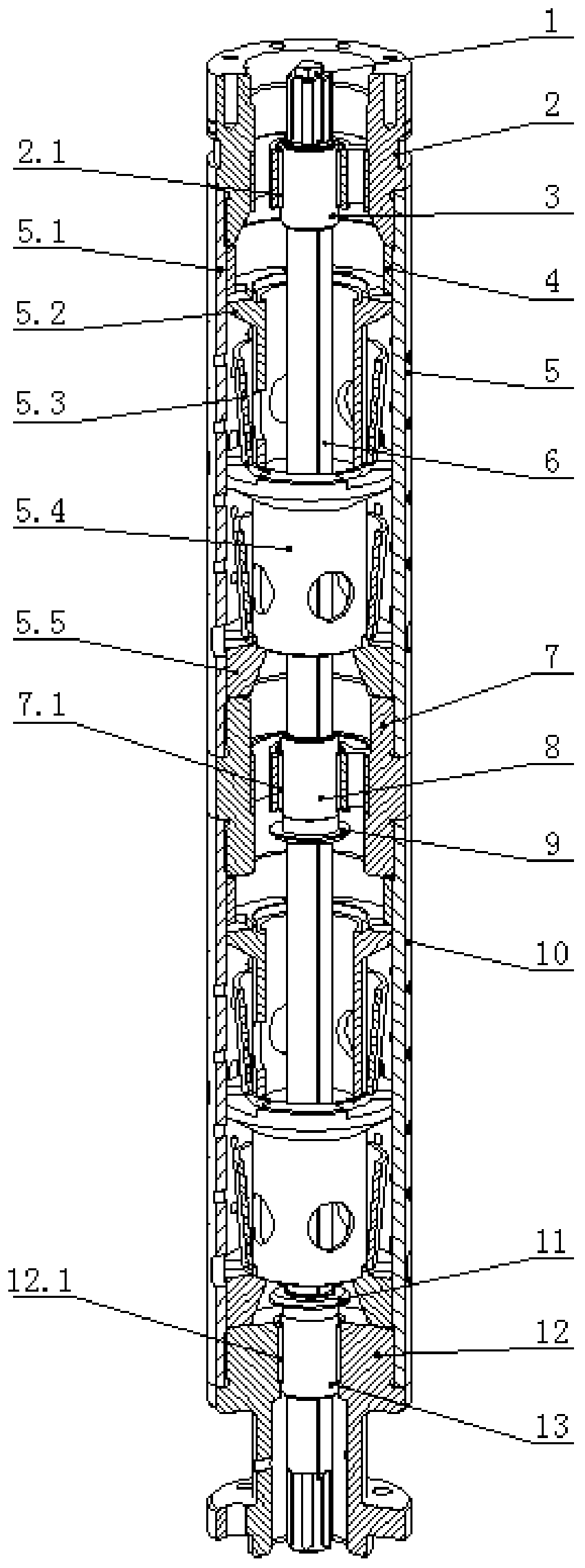

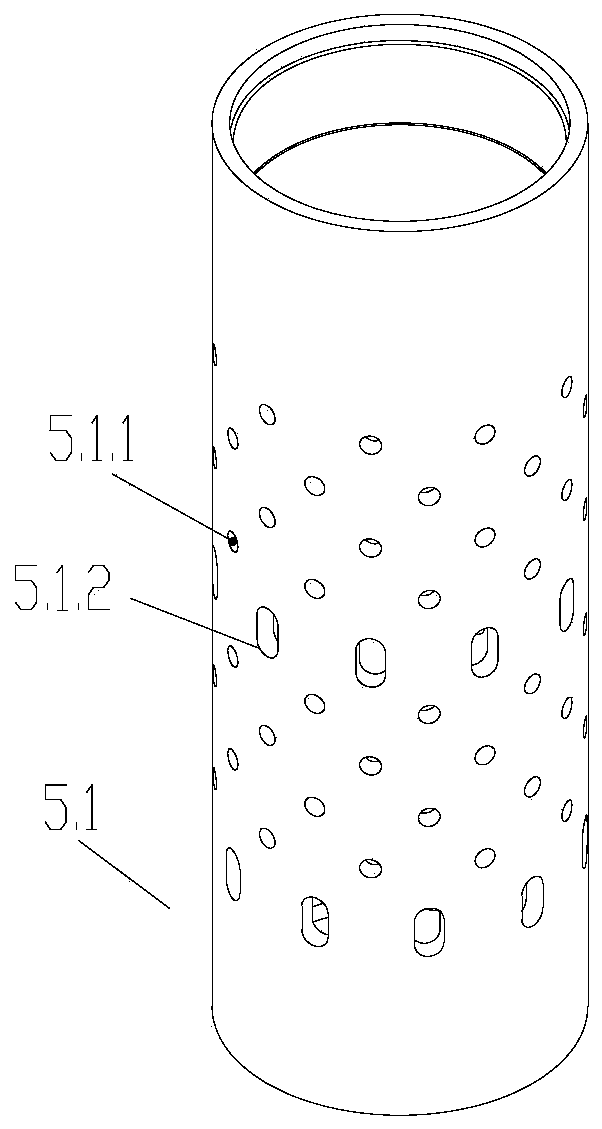

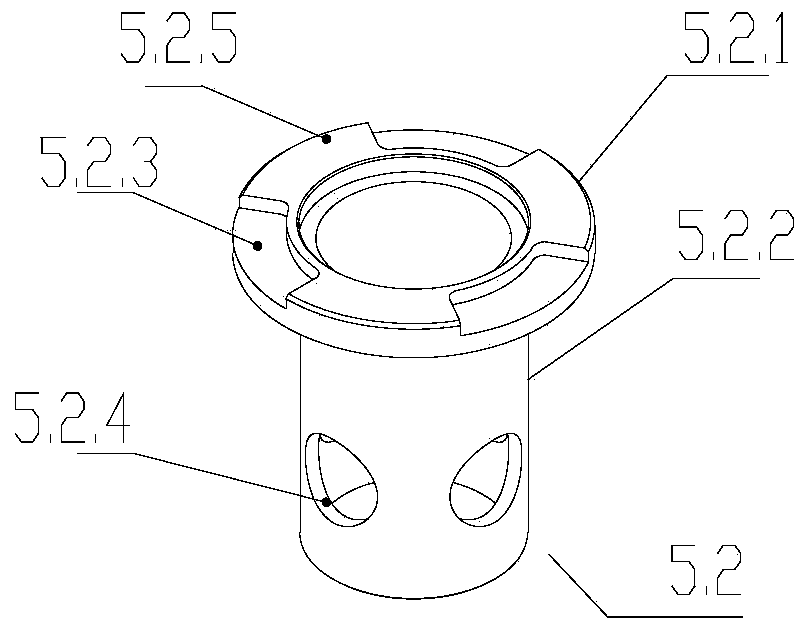

[0039] Such as Figure 1 to Figure 3 As shown, the present invention discloses a sand-blocking suction port of a submersible pump, which includes an upper suction chamber 5 and a lower suction chamber 10 which have the same structure and are connected in series along the axial direction; the axial centers of the two suction chambers are provided with The same connecting shaft 6; each of the suction chambers includes a cylindrical housing 5.1;

[0040] The casing 5.1 is a porous screen structure, and the surface of the casing 5.1 is provided with several transparent outer liquid inlet holes 5.1.1 and sand discharge holes 5.1.2 along the radial direction. Preferably, the outer liquid inlet holes 5.1.1 are multiple rows of circular holes unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com