Circulating glaze spraying line base

A base and glaze spraying technology, applied in the field of circulation lines, can solve problems such as inability to adapt to different products, imperfect circulation lines, and inability to adjust the length of circulation lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

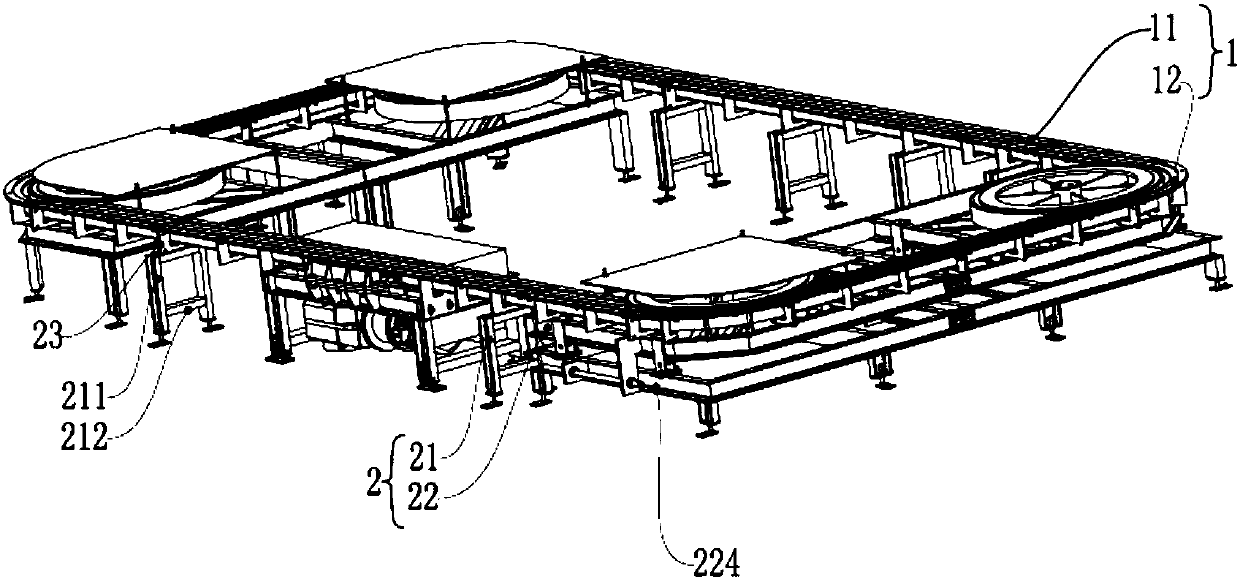

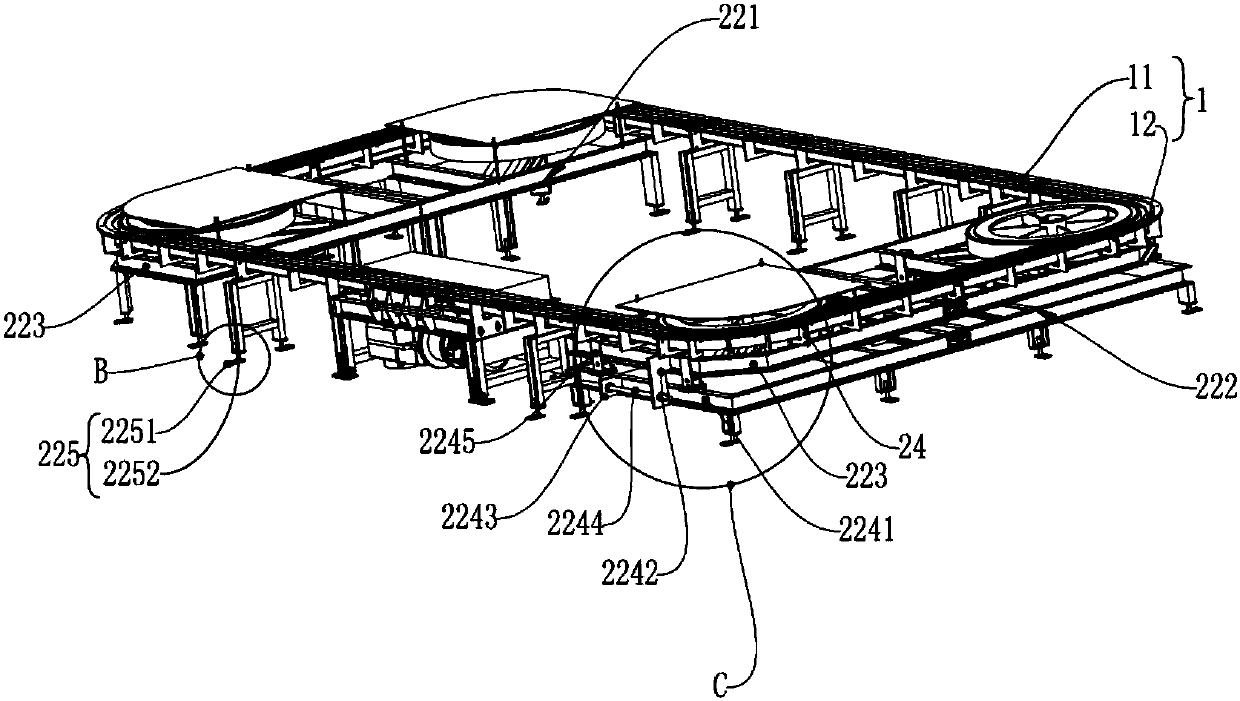

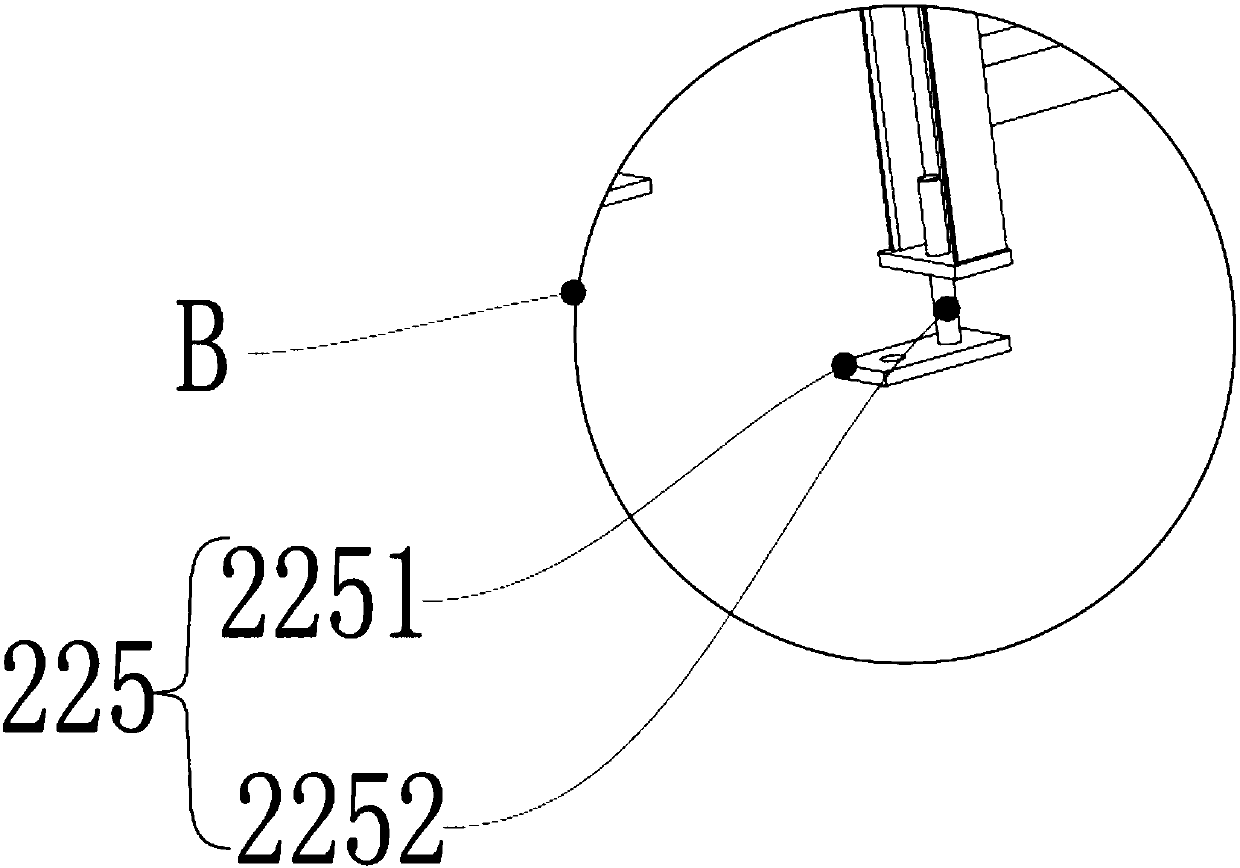

[0071] Such as Figure 1 to Figure 9 As shown, a circulating glazing line base includes a guide rail 1 and a support mechanism 2. The guide rail 1 includes a plurality of straight-line segment guide rails 11 and arc-shaped segment guide rails 12, and a plurality of the straight-line segment guide rails 11 and arc-shaped segment guide rails The guide rail 12 forms a closed rectangular structure, and the apex of the rectangular structure is an arc-shaped structure;

[0072] The support mechanism 2 includes a straight line section support frame 21 and an arc section support frame 22;

[0073] There are multiple straight section support frames 21, which are respectively arranged on the straight section guide rails 11;

[0074] The arc section support frame 22 has at least two, which are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com