Universal light composite outer wall plate in integration of wall body and plastering thermal insulation and manufacturing method of universal light composite outer wall plate

A composite exterior wall panel, integrated technology, used in thermal insulation, walls, building components and other directions, can solve the problems of complex construction, easy cracks in the external thermal insulation system, heavy weight, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

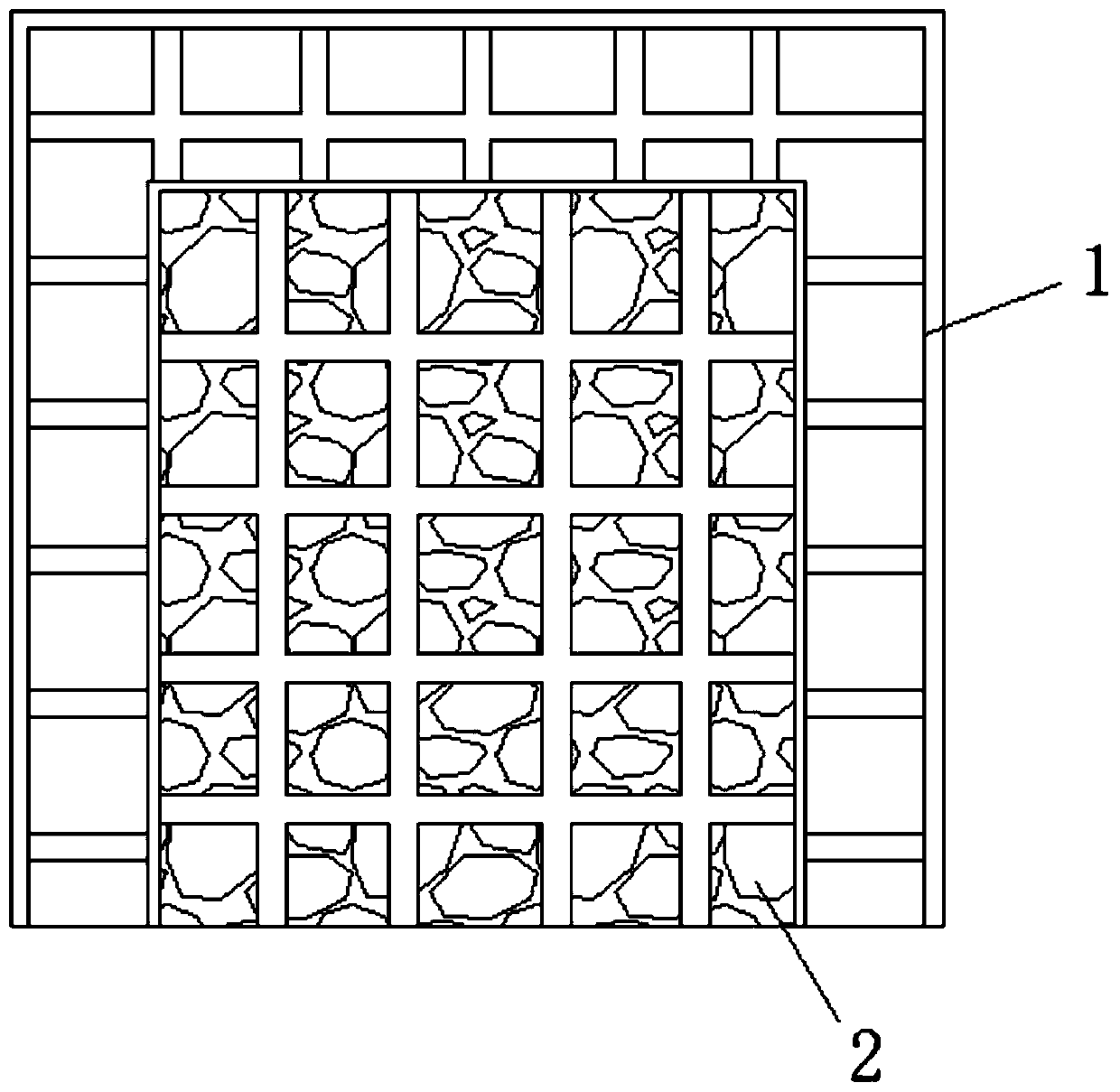

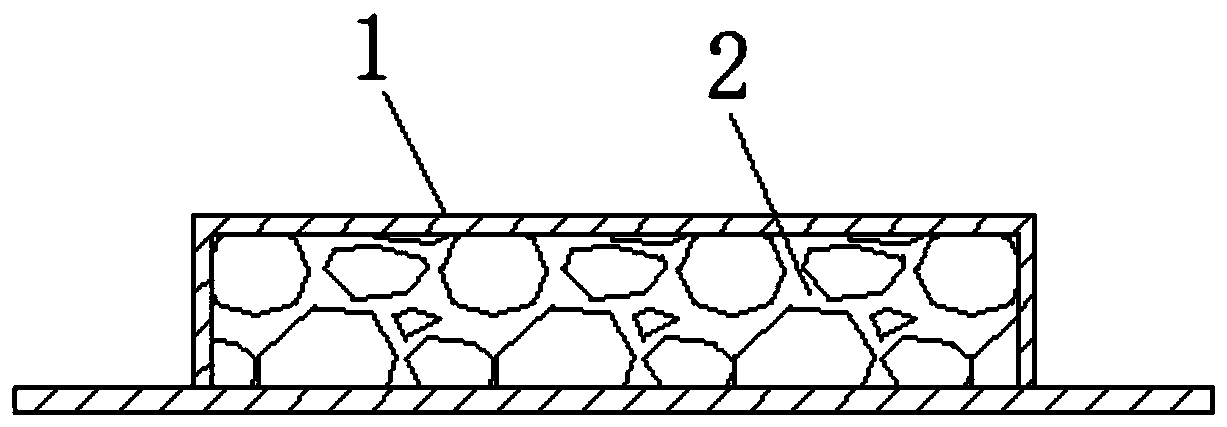

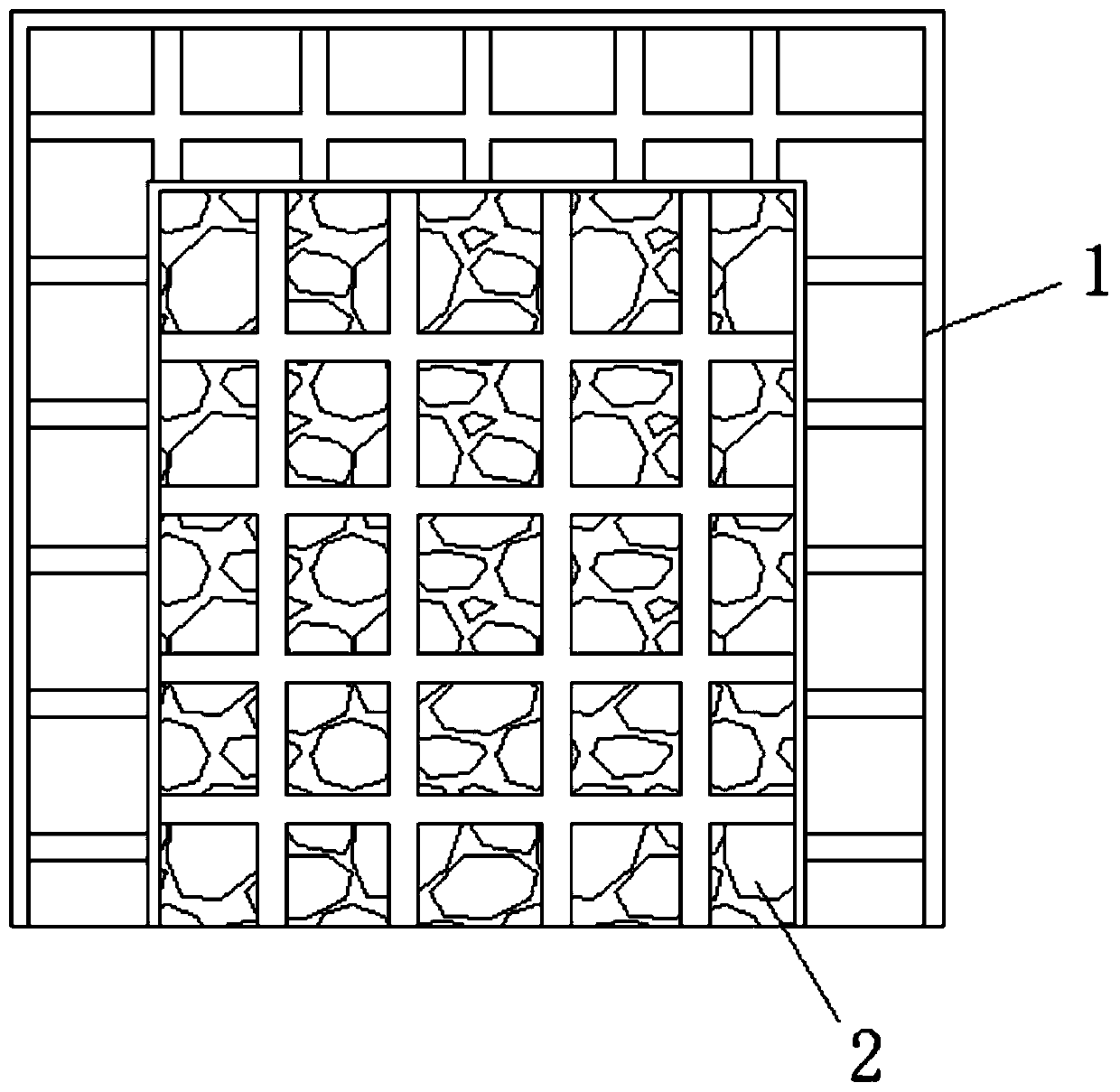

[0019] refer to Figure 1-2 , a general-purpose lightweight composite exterior wall panel integrating wall body and plastering insulation, including a U-shaped steel wire mesh frame 1 and an insulating core board 2, and the front and back sides of the insulating core board 2 and both sides are clamped on the U-shaped steel wire mesh The inner side of the frame 1, and one side of the front surface of the U-shaped steel wire mesh frame 1 is flush with the insulation core board 2, and the other three sides are longer than the insulation core board 2. The two sides of the U-shaped steel wire mesh frame 1 and the insulation core board 2 The spacing is 1mm, the upper and lower sides of the insulation core board 2 are covered with waterproof and anti-cracking mortar or cement mortar with a perimeter of 50mm in width and 5mm in thickness, and a thickness of 15mm in other areas. , 1 part of lime, 4 parts of glue, 1 part of water-repellent agent, insulation core board 2 uses straw powde...

Embodiment 2

[0025] refer to Figure 1-2 , a general-purpose lightweight composite exterior wall panel integrating wall body and plastering insulation, including a U-shaped steel wire mesh frame 1 and an insulating core board 2, and the front and back sides of the insulating core board 2 and both sides are clamped on the U-shaped steel wire mesh The inner side of the frame 1, and one side of the U-shaped steel wire frame 1 is flush with the insulation core board 2, and the other three sides are longer than the insulation core board 2. The distance between the two sides of the U-shaped steel wire frame 1 and the insulation core board 2 is 1.3 mm, the upper and lower sides of the insulation core board 2 are covered with cement mortar with a perimeter of 50 mm wide and 5 mm thick, and other areas with a thickness of 15 mm and a thickness of 1:3. According to the volume, 13 parts of straw minced fiber, 3 parts of expanded perlite, and additional lime 1.3 Quantity, 3.3 parts of glue, 1.3 parts ...

Embodiment 3

[0031] refer to Figure 1-2 , a general-purpose lightweight composite exterior wall panel integrating wall body and plastering insulation, including a U-shaped steel wire mesh frame 1 and an insulating core board 2, and the front and back sides of the insulating core board 2 and both sides are clamped on the U-shaped steel wire mesh The inner side of the frame 1, and one side of the U-shaped steel wire frame 1 is flush with the insulation core board 2, and the other three sides are longer than the insulation core board 2. The distance between the two sides of the U-shaped steel wire frame 1 and the insulation core board 2 is 1.5 mm, the upper and lower sides of the thermal insulation core board 2 are covered with cement mortar with a perimeter of 50 mm wide and 5 mm thick, and other areas with a thickness of 15 mm and a thickness of 1:3. According to the volume, 15 parts of rice straw minced fiber, 8 parts of expanded perlite, and the thermal insulation core board 2 pass Shred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com