Thread chip filter locking structure and washing machine

The technology of a lint filter and locking structure, which is applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of high cost, difficulty in reliability and implementation, and achieve low cost, high stability and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

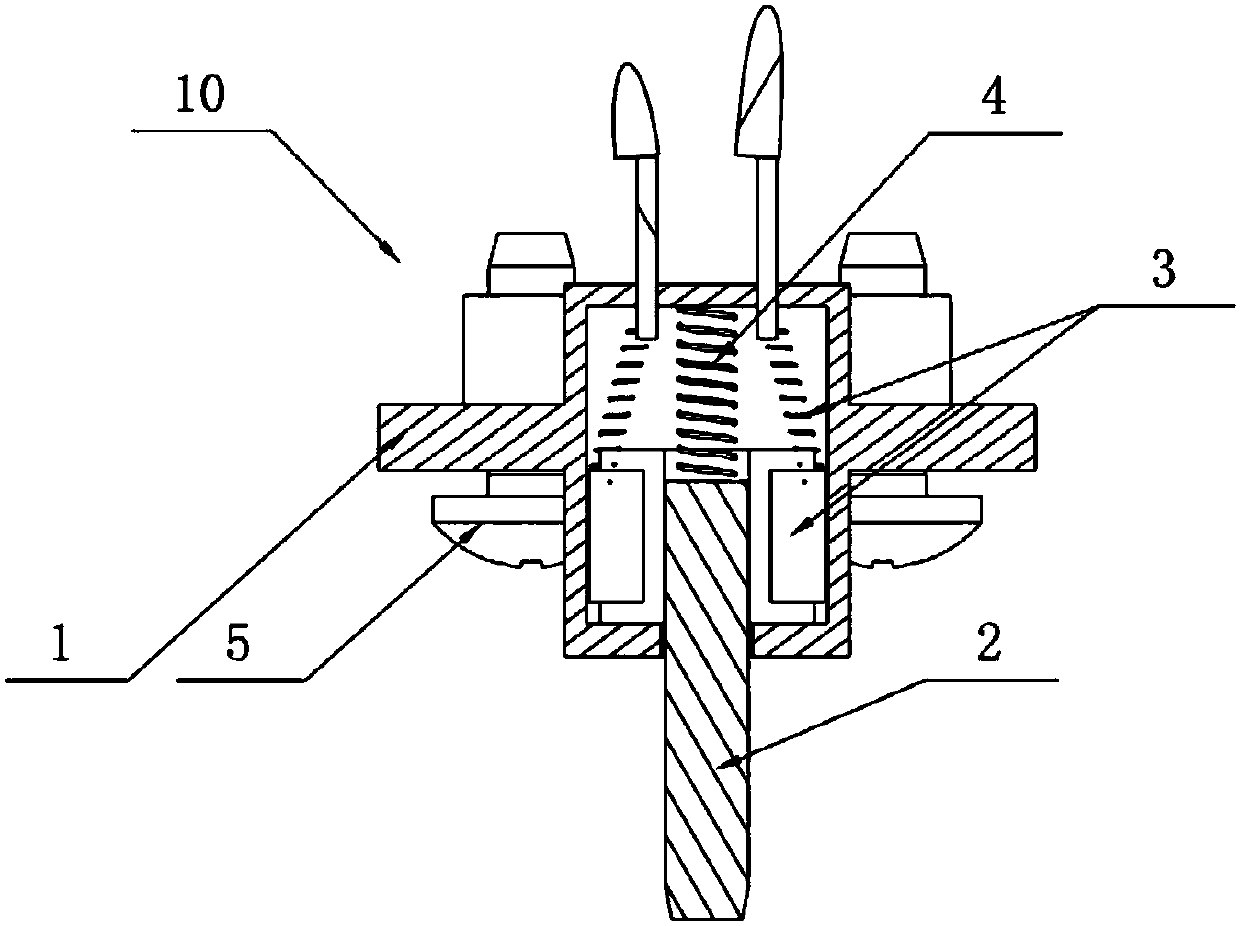

[0029] This embodiment provides a lint filter locking structure 10, such as Figure 1-3 As shown, the lint filter locking structure 10 includes a mounting base 1 fixedly installed on the washing machine body 20, and a locking column 2 with one end passing through the mounting base 1 and capable of moving along its own axis. Specifically, in this embodiment, the above-mentioned mounting base 1 is fixed on the machine body 20 of the washing machine by four uniformly distributed screws 5 . The above-mentioned locking post 2 is arranged vertically, and when the locking post 2 moves downward, its other end can prevent the knob 301 of the lint filter 30 from being unscrewed, so as to achieve the purpose of locking the lint filter 30 .

[0030] Specifically, such as figure 1 As shown, the above-mentioned mounting seat 1 of this embodiment is provided with an electromagnetic coil 3, the above-mentioned locking column 2 is a steel column, and the locking column 2 is penetrated in the ...

Embodiment 2

[0039] The difference between this embodiment and the first embodiment is that the way of driving the locking column 2 is different, please refer to Figure 5 In this embodiment, a linear motor 6 is provided in the mounting base 1, the output end of the linear motor 6 is connected to the locking column 2, and the linear motor 6 can drive the locking column 2 to move downward and insert it into the groove 302 of the knob 301 , so as to prevent the knob 301 from being unscrewed, so as to realize the locking of the lint filter 30 . When the locking of the lint filter 30 needs to be released, the linear motor 6 drives the locking post 2 to move upward.

[0040] In this embodiment, the linear motor 6 is provided to drive the locking column 2 to move up and down, which can further simplify the structure of the lint filter locking structure 10 .

[0041] This embodiment also provides a washing machine, including the above-mentioned lint filter locking structure 10 , a machine body 2...

Embodiment 3

[0043] The difference between this embodiment and the first embodiment is that the locking method of the locking column 2 to the knob 301 is different. In this embodiment, a magnet is arranged on the top or side wall of the knob 301. When the locking column 2 moves downward, it will be attracted by the magnet. . The locking post 2 and the lint filter 30 are locked by the attraction of the magnet.

[0044] The present invention also provides a washing machine, comprising the above-mentioned lint filter locking structure 10 , a machine body 20 and a lint filter 30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com