Two-stage cavitation generator with composite structure

A composite structure and generator technology, applied in the field of cavitation generators, can solve problems such as failure to restore the initial pressure value in time, failure to ensure smooth completion, failure to ensure cavitation effects, etc., to achieve strong cavitation effects, compact structure, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

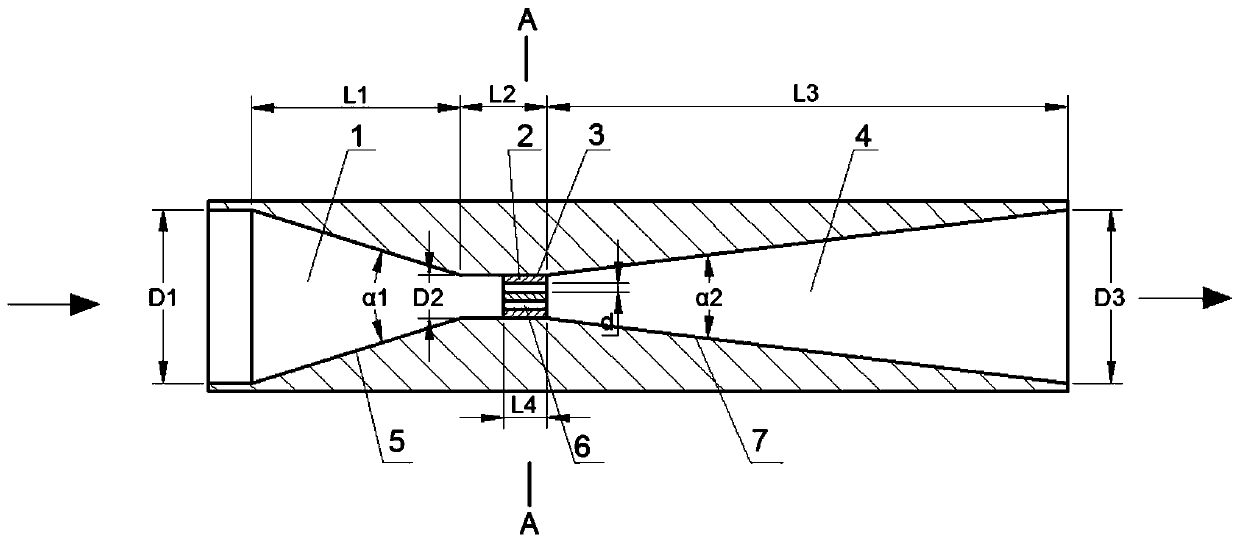

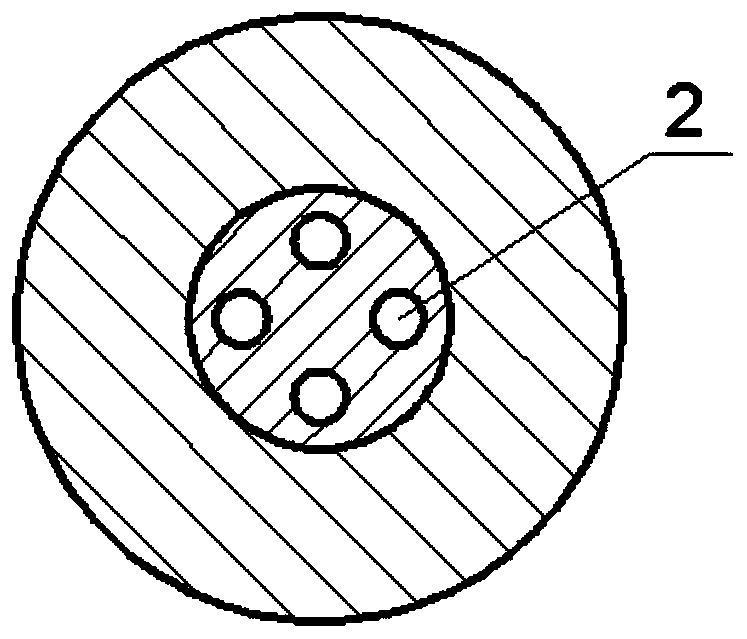

[0025] like Figure 1-Figure 2 As shown, it is a two-stage cavitation generator of a composite structure of the present invention, including a Venturi tube and an orifice plate 2, wherein the Venturi tube has a tubular appearance, and consists of an inlet end 1, a tapered section 5, a throat Section 3 , expanding section 7 , outlet end 4 , the orifice plate 2 is provided with a number of holes 6 , which are arranged in the throat section 3 .

[0026] The tapered section 5 is a frustum-shaped inner hole, and its central angle α 1 is 30°~50°; the expanding section 7 is a frustum-shaped inner hole, and its central angle α 2 It is 18°~30°.

[0027] The inlet end 1 is a round pipe with equal inner diameter connected to the tapered section 5 , and the outlet end 4 coincides with the divergent section 7 .

[0028] The diameter of the orifice plate 2 is equal to the section diameter of the throat section 3, and the relational expression between the quantity of the holes 6 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com