Rotary liquid whistle cavitation generator

A generator and rotor technology, which is applied in the field of rotating liquid whistle cavitation generators, can solve problems affecting cavitation efficiency, large liquid axial back-mixing, etc., to achieve improved cavitation intensity, small axial back-mixing, and improved the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

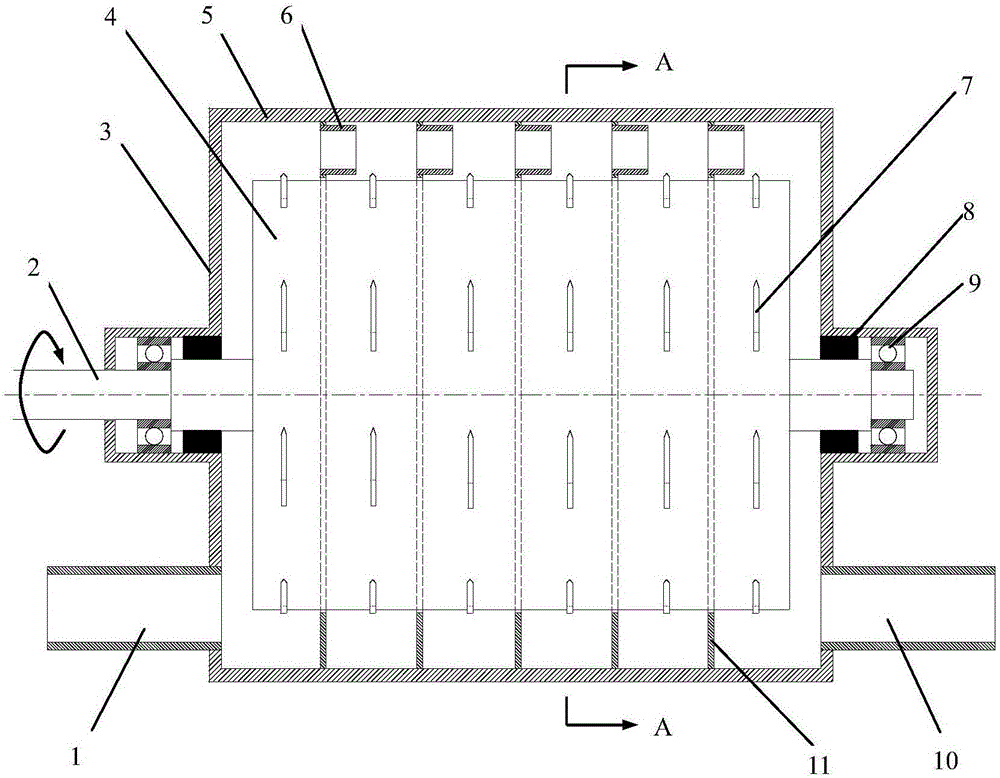

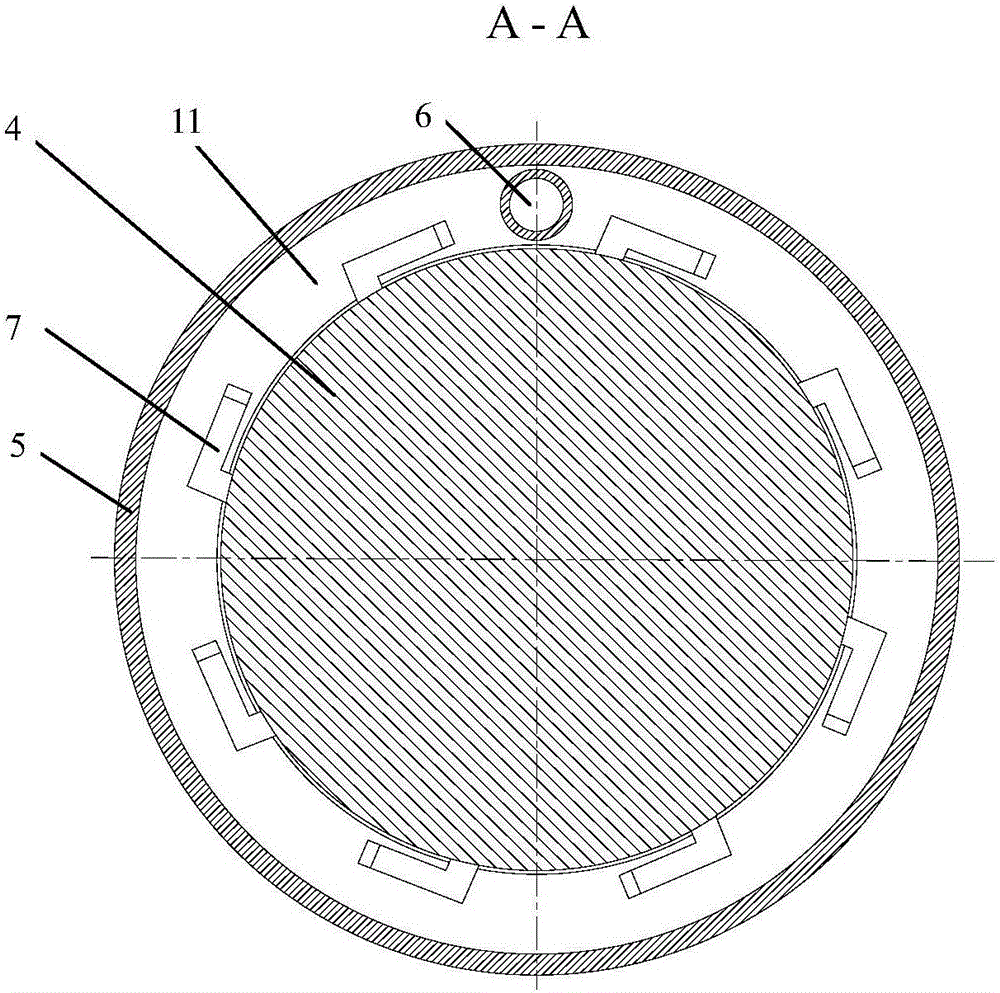

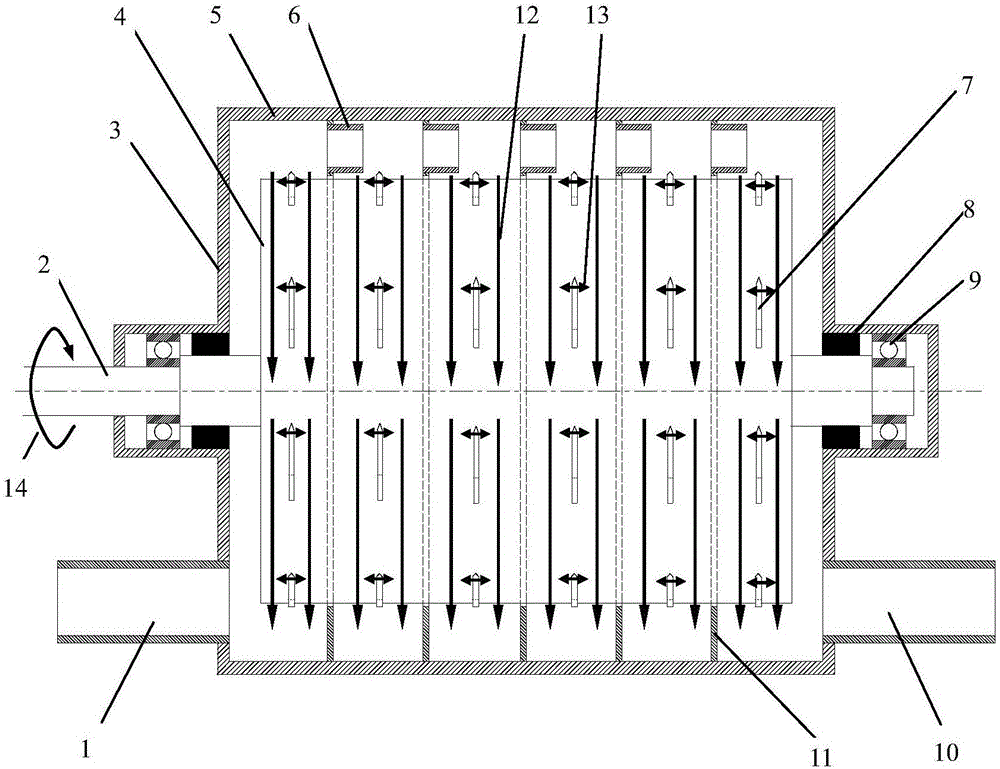

[0048] The rotating liquid whistle cavitation generator includes a coaxial rotor 4, a casing 5 and a rotating shaft 2, the rotor 4 is fixedly sleeved on the rotating shaft 2, and the casing 5 is placed outside the rotor 4. The two sides of the casing 5 The end is provided with a bearing 2, the rotating shaft 2 is rotatably connected to the housing 5 through the bearing, and one end of the rotating shaft 2 passes through the housing 5 and is connected to a power device for output torque;

[0049] A sealing device 8 is provided between the two ends of the housing 5 and the rotating shaft, there is a gap between the inner wall surface of the housing 5 and the outer wall surface of the rotor 4, and the inner wall surface of the housing 5 , the outer wall surface of the rotor 4 and the sealing device 8 form a sealed inner cavity;

[0050] One end of the housing 5 is provided with a liquid inlet 1, and the other end of the housing 5 is provided with a liquid outlet 10, and both the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com