Band saw cutting equipment and sawing method thereof on major engineering site

A band saw and engineering technology, applied in the field of intelligent manufacturing, to achieve the effect of reducing material waste, improving sawing efficiency, and ensuring sawing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

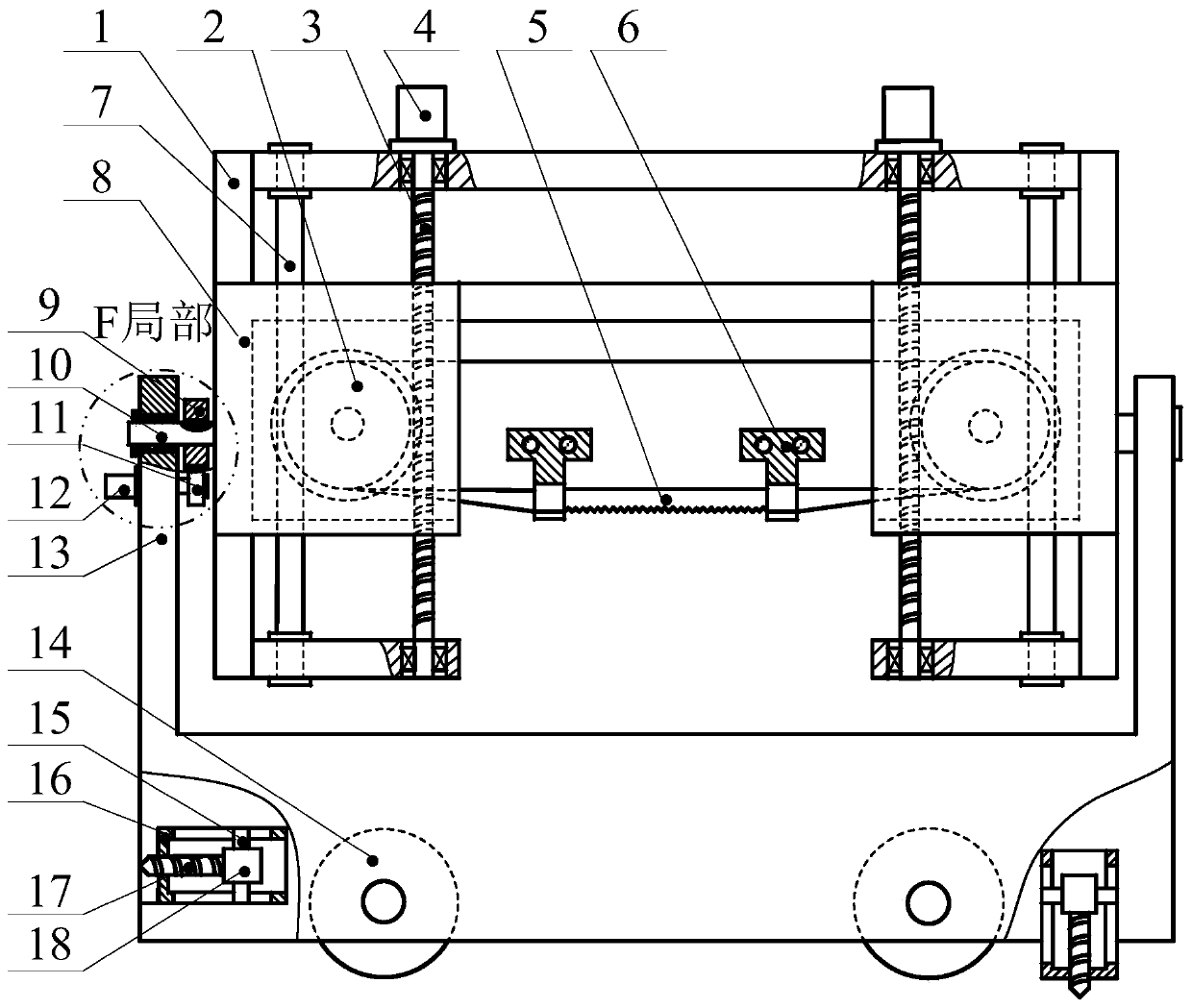

[0026] Such as figure 1 As shown, a major engineering site band saw cutting equipment, including gantry 1, band saw wheel 2, saw band 5, guide column 7, saw frame 8, swing shaft 10, frame 13, roller 14, workbench, guide Block 6, feed drive assembly, tangential adjustment drive assembly and piling fixing mechanism. The bottom of the frame 13 supports four rollers 14 . The rollers 14 help the frame to move under the drag of the vehicle, so that the present invention can be flexibly dragged to different major engineering sites for sawing operations. Workbench is installed on the frame 13.

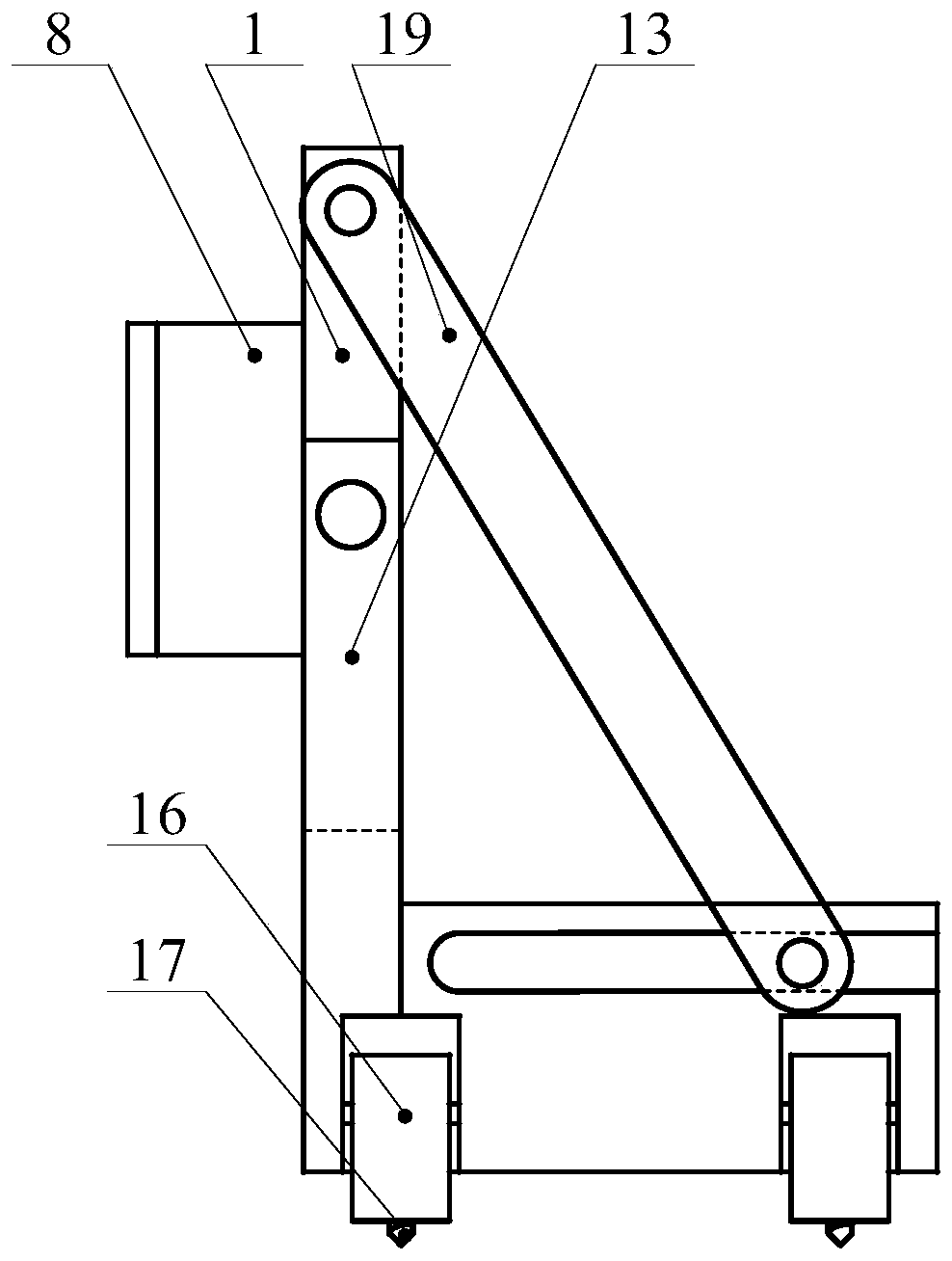

[0027] Such as figure 1 , 2 Shown in and 3, the two ends of gantry frame 1 all form rotating pair with frame 13 by swing shaft 10. The gantry 1 is positioned directly above the workbench. The swing axis 10 is fixed with the portal frame 1. The tangential adjustment drive assembly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com