A corner splint positioning and tensioning device

A technology of tensioning device and splint, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problem that the position of the grabbing ring is not fixed, the force cannot be accurately controlled, and the positioning of the tensioning device is difficult. deformation and other problems, to achieve the effects of labor-saving and convenient pressing and loosening operations, easy automation of operations, and improvement of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

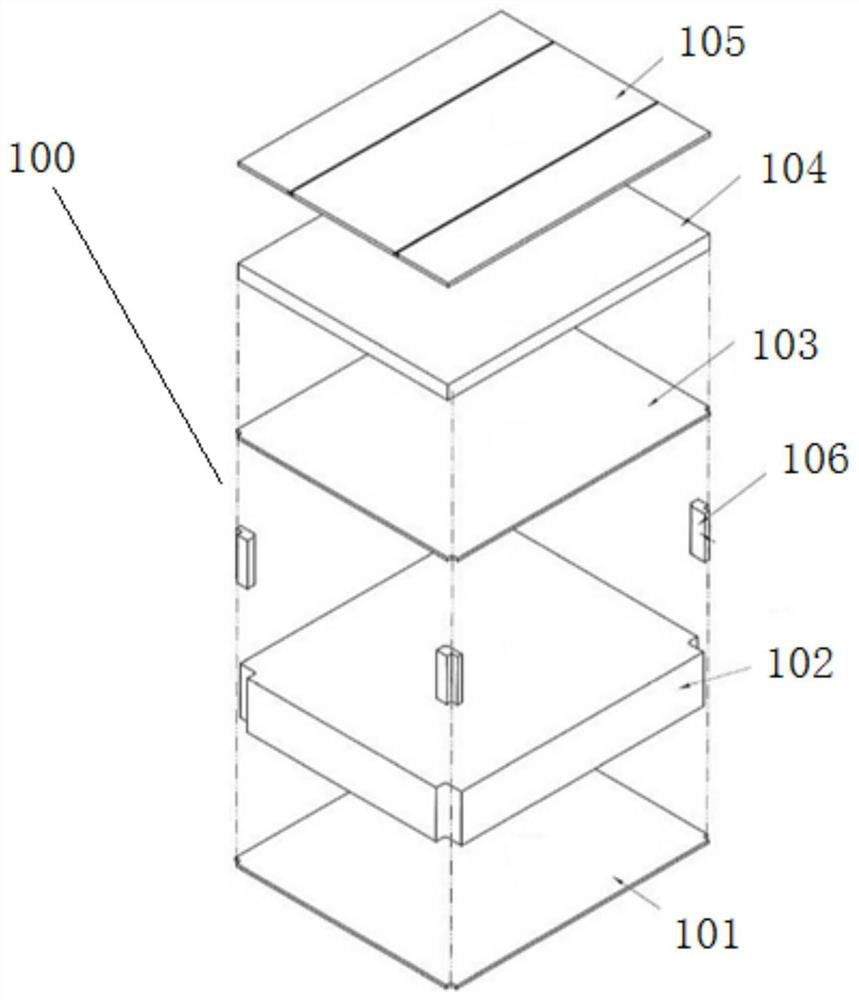

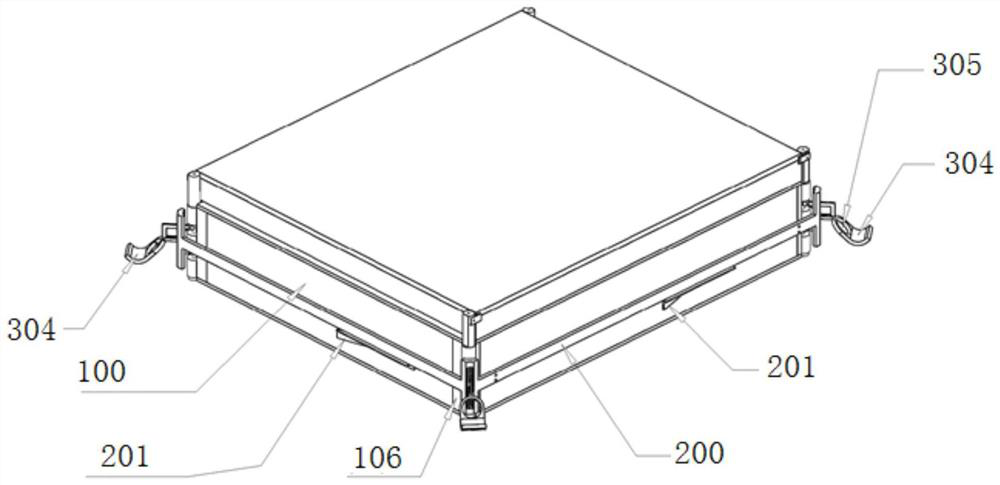

[0056] In order to achieve figure 1 In the illustrated fixing of the insulating box 100 in the curing stage after gluing, this embodiment proposes a corner splint positioning and tensioning device. The insulating box 100 has a five-layer structure, including the second board 102 (ie, the base plate), and the first board 101, the third board 103, the fourth board 104, and the fifth board 105 bonded and compounded on the upper and lower surfaces of the second board 102. Wherein, the four end corners of the No. 2 board 102 are provided with first concave right-angle grooves perpendicular to the upper and lower surfaces, and a corner splint 106 is bonded in the first concave right-angle groove. The outside of the corner splint 106 is connected to the first inner The second concave right-angle groove is parallel to the second concave right-angle groove.

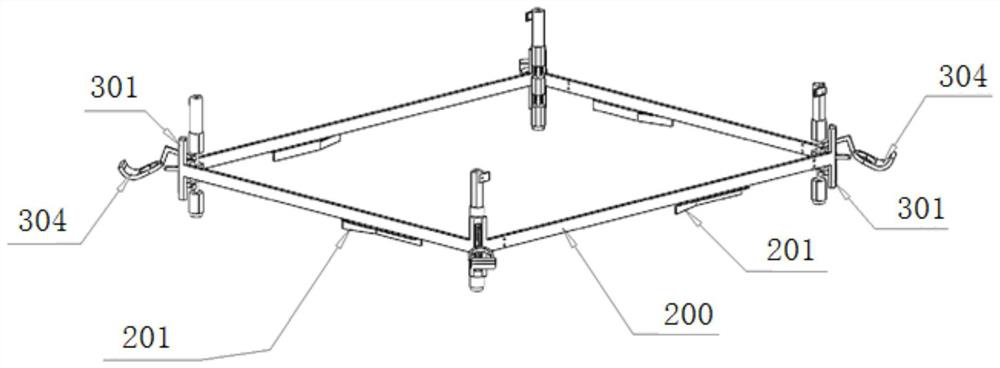

[0057] See figure 2 As shown, the positioning and tensioning device includes an outer frame 200 whose inner size is not less than ...

Embodiment 2

[0067] The difference from Embodiment 1 is that the insulating box 100 targeted by the positioning and tensioning device in this embodiment has only a three-layer structure, that is, it includes the No. 1 board 101, the No. 2 board 102, and the No. 3 board 103. Therefore, correspondingly, the limiting rod 308 above the pressing roller 309 of the positioning and tensioning device in this embodiment is relatively short, and the limiting baffle 310 is not installed.

[0068] In the above embodiments, the surface of the component that is close to or in contact with the adhesive surface of the positioning and tensioning device and the insulating box 100 is made of anti-adhesive material. The anti-adhesive material is preferably polytetrafluoroethylene. The components include a pressing roller 309, a limit bar 308, a limit baffle 310 and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com