OLED illumination screen body connected in series with light-emitting component and preparation method thereof

A technology of light-emitting elements and light-emitting layers, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and electric solid-state devices, and can solve problems such as high proportion of short-circuit failure current and affecting lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

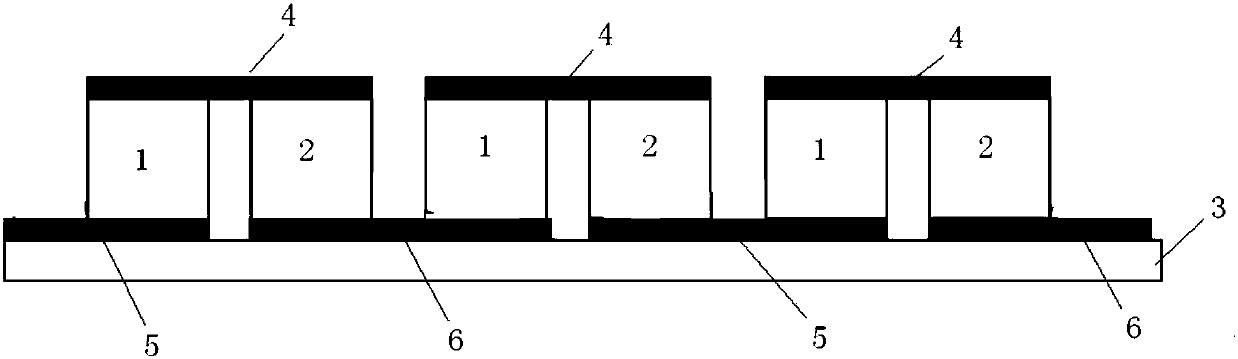

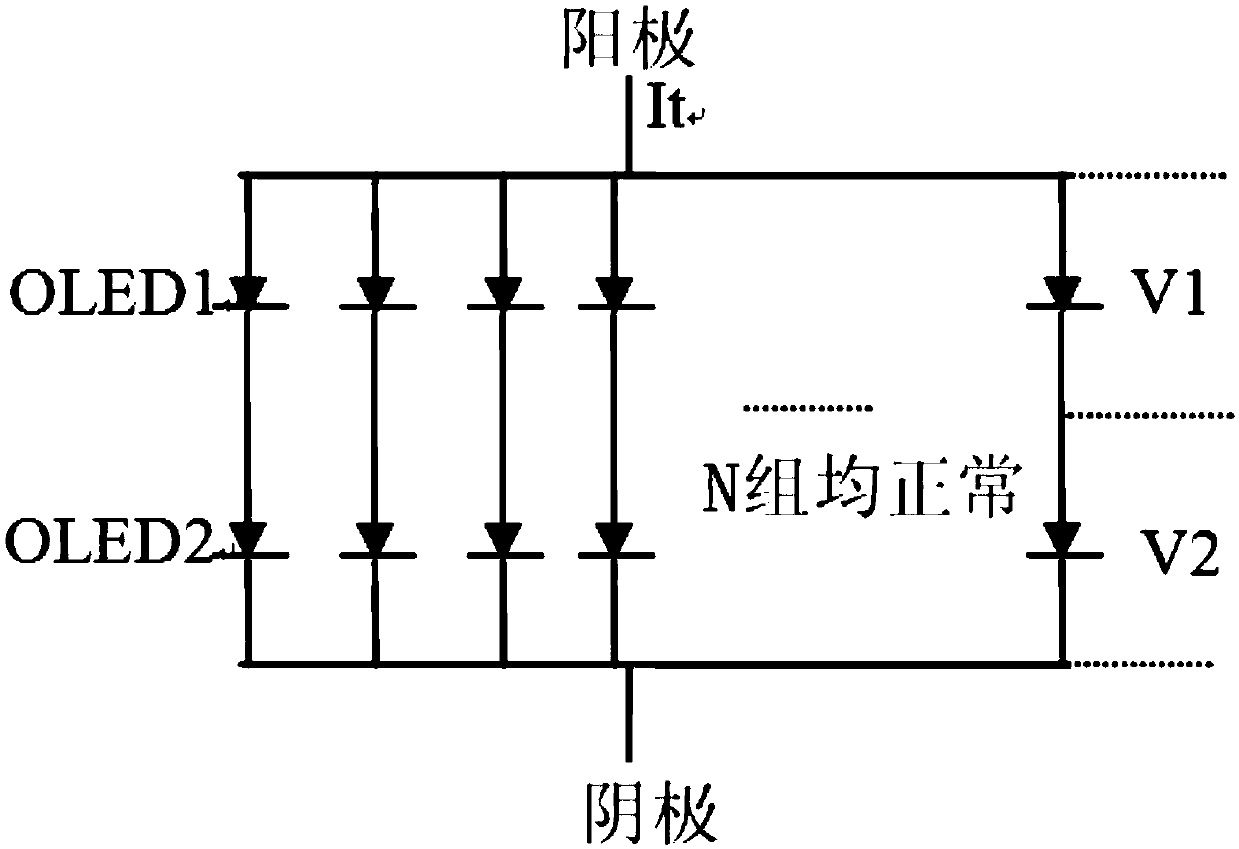

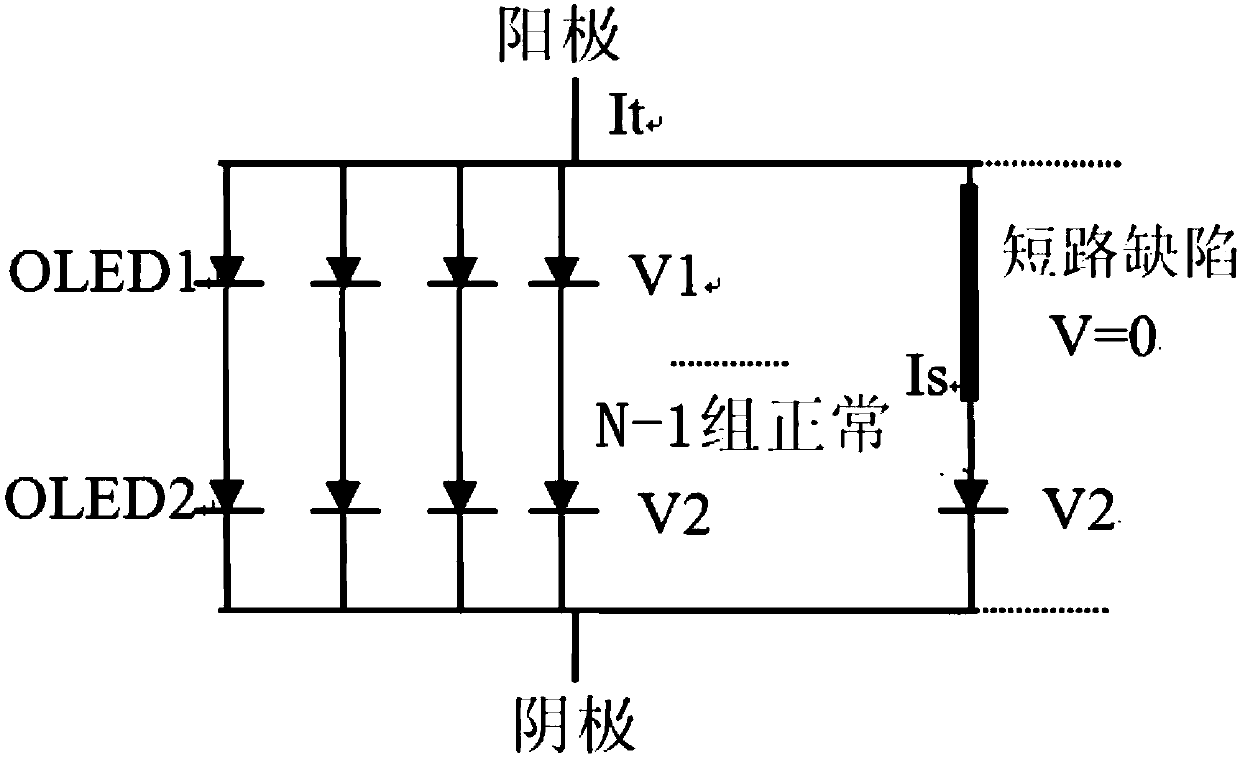

[0036] This embodiment provides an OLED lighting screen body in which light-emitting elements are connected in series, which includes a substrate and a plurality of light-emitting elements arranged on the substrate. The substrate is divided into N light-emitting areas, and each light-emitting area includes M light-emitting elements connected in series through metal, wherein M and N are both integers and M≥2, N≥50. It is sufficient that the metal can achieve electrical conductivity, preferably a single layer of aluminum material, a single layer of silver material, or a stacked arrangement of an aluminum material layer and a silver material layer.

[0037] by figure 1The screen body shown is taken as an example, in which a plurality of light-emitting elements 1 (2) are arranged on the substrate 3, and the light-emitting element 1 and the light-emitting element 2 are divided into a group in the figure, wherein the first electrode of the light-emitting element 1 and the light-emit...

Embodiment 2

[0056] In the OLED lighting screen body in which the light-emitting elements are connected in series provided in this embodiment, such as Figure 4 As shown, it also includes an auxiliary electrode 7 disposed between the light-emitting elements and electrically connected to the metal; an insulating layer 8 covers the auxiliary electrode 7 . For this reason, the sheet resistance of the auxiliary electrode can be selected to be less than or equal to 2Ω / □. The auxiliary electrode 7 can further play a role of preventing short circuit.

[0057] In addition, the width of the metal in this embodiment satisfies the following condition: when more than a set number of light-emitting elements in the light-emitting region have short-circuit defects, the metal will be fused. That is to say, when multiple light-emitting elements are short-circuited, that is, a severe short-circuit phenomenon, the metal is fused to form an open circuit protection mechanism. For example, if there are two li...

Embodiment 5

[0059] This embodiment provides an OLED lighting screen body and its preparation method. Each light-emitting area of the OLED lighting screen body includes a common type first electrode and a set of separate type first electrodes such as Figure 5a As shown, wherein the number of separated first electrodes is N, the preparation method comprises the following steps:

[0060] Step 1: Prepare a plurality of common-type first electrodes 11 and multiple sets of separate-type first electrodes 12 on the substrate, each set of separate-type first electrodes includes P separate-type first electrodes 12, and P The separate first electrodes 12 are arranged in sequence along the length direction of the common first electrodes 11 . Figure 5a In the diagram, a common type first electrode 11 and a group of separate type first electrodes 12 are taken as an example for schematic illustration. In practical application, more electrodes may be distributed according to this arrangement. The pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com