Large-size graphene foaming plate

A graphene foam, large-size technology, applied in the field of foam boards, can solve the problems of graphene foam boards not being firmly spliced, easy to fail connections, etc., to achieve the effect of increasing strength and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

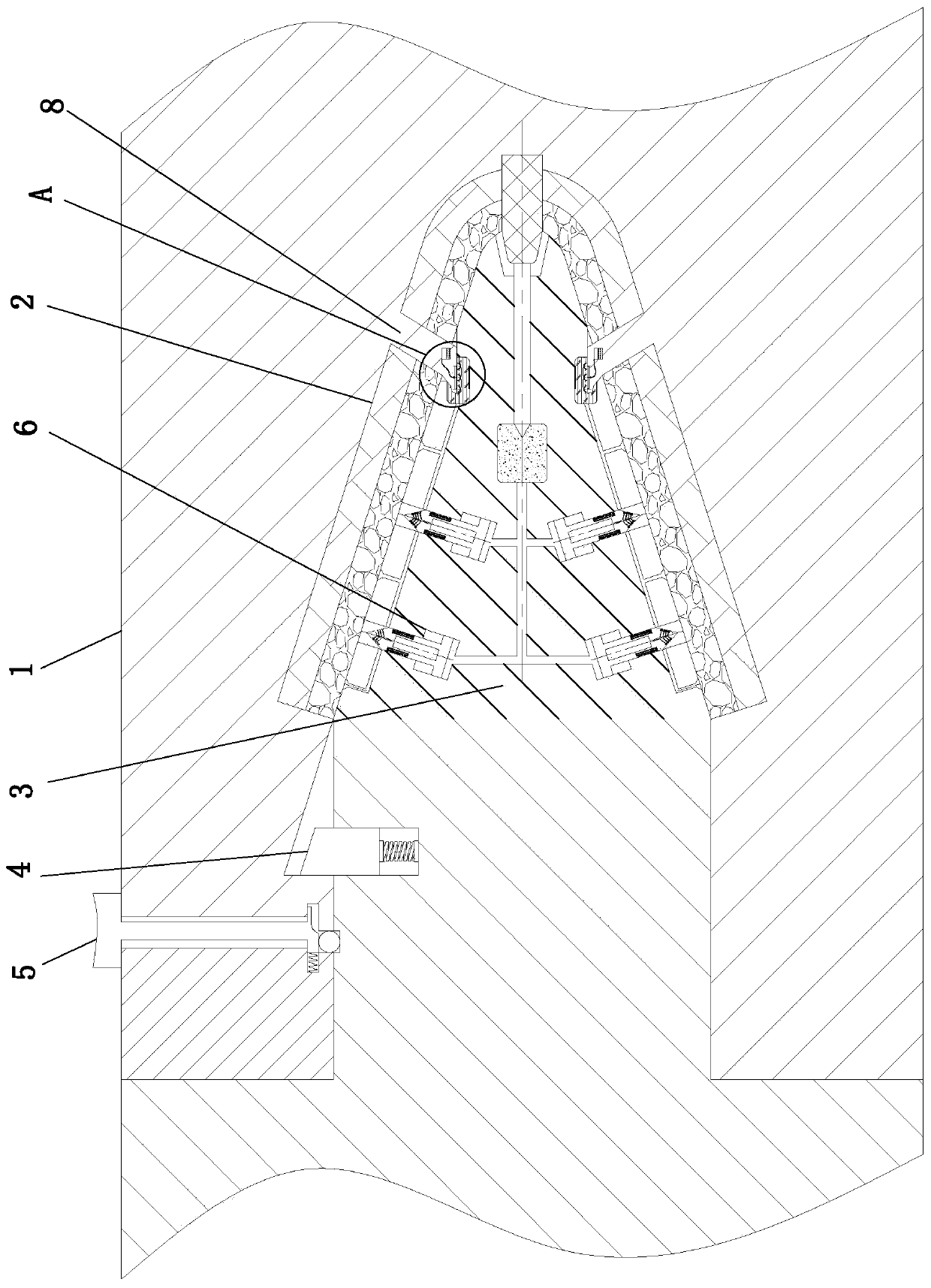

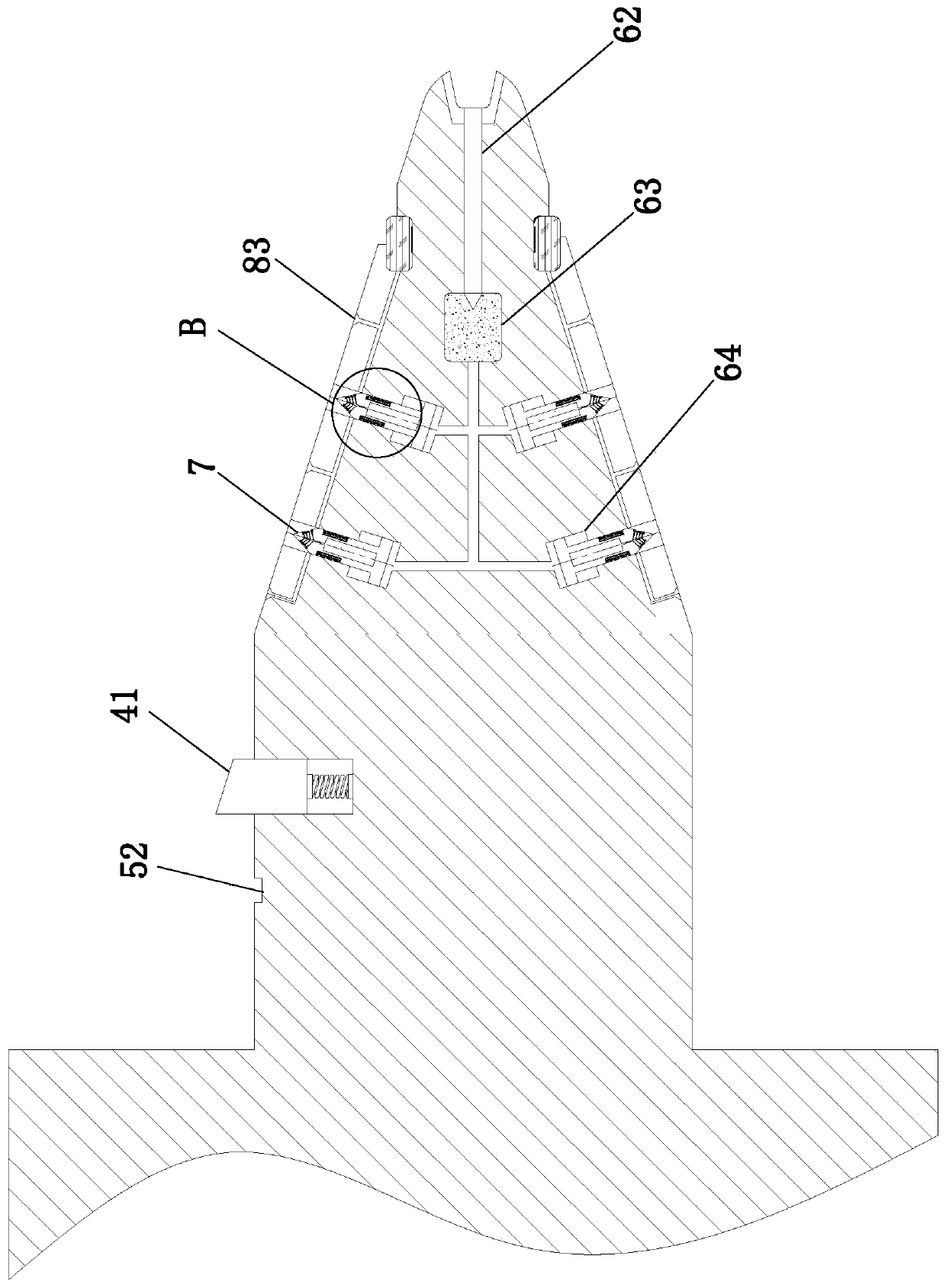

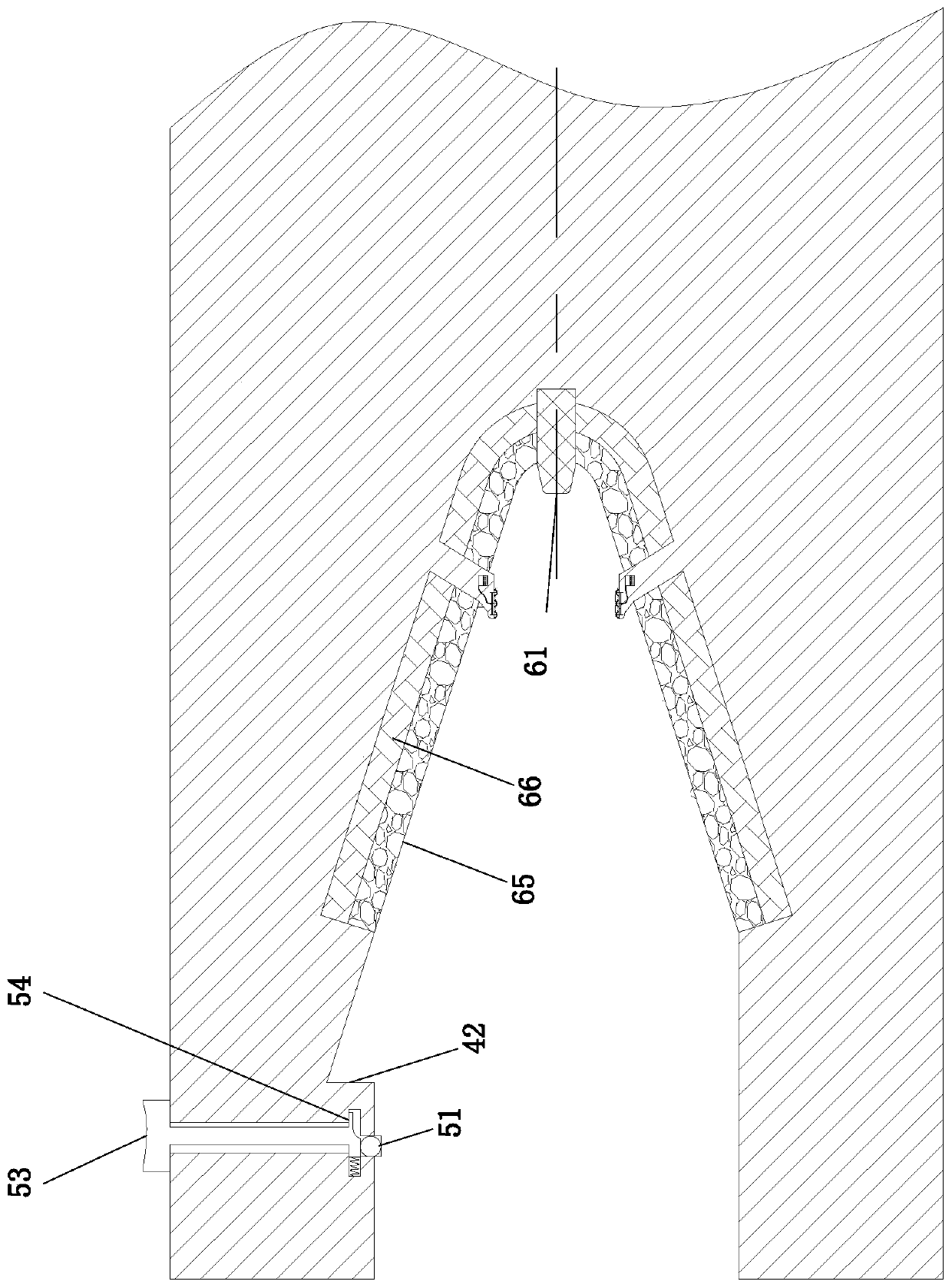

[0026] As a specific embodiment of the present invention, the locking unit 5 includes a steel ball 51, a locking groove 52, a push handle 53, and a top bar 54; the limiting groove 42 is opened on the side close to the opening of the V-shaped slot 2 There is a push hole, which is a waist-shaped hole. The push hole is sleeved with a push handle 53. The push handle 53 can slide left and right along the push hole. The end of the push handle 53 away from the outside of the V-shaped slot 2 is provided with a top cavity, and the push handle 53 The other end is provided with an arc-shaped groove, which is convenient for finger pressing; a top bar 54 is provided in the top cavity, a spring is arranged between one end of the top bar 54 and the top cavity, and both ends of the spring are connected to the top cavity and the top bar 54 respectively. The push handle 53 is fixed to the top bar 54 and the thickness of one end of the top bar 54 close to the spring is greater than the other end; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com