On-line detection device for feeding speed of primary hopper

A detection device and secondary material technology, which is applied in the direction of jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as unstable feeding, hidden dangers of pouring quality in combustion chambers, etc., to ensure stability, reduce human intervention, The effect of avoiding the problem of stomata

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

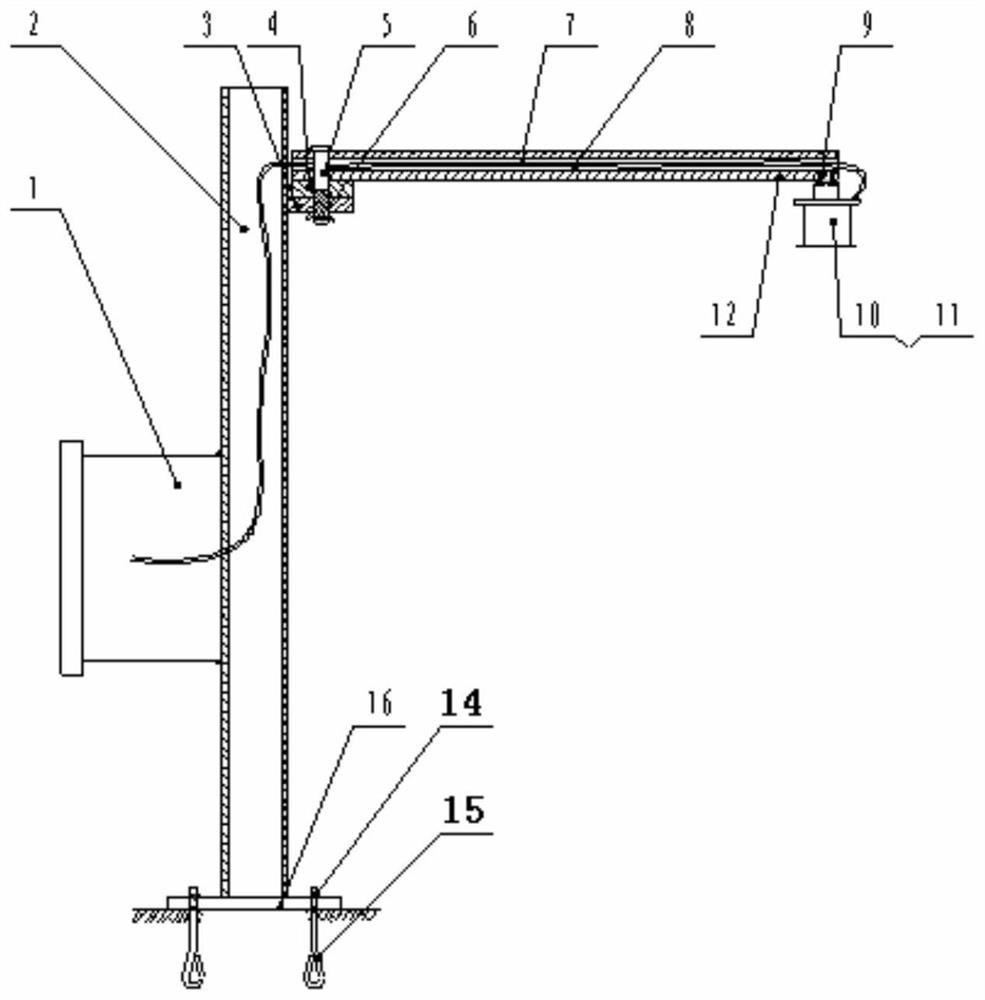

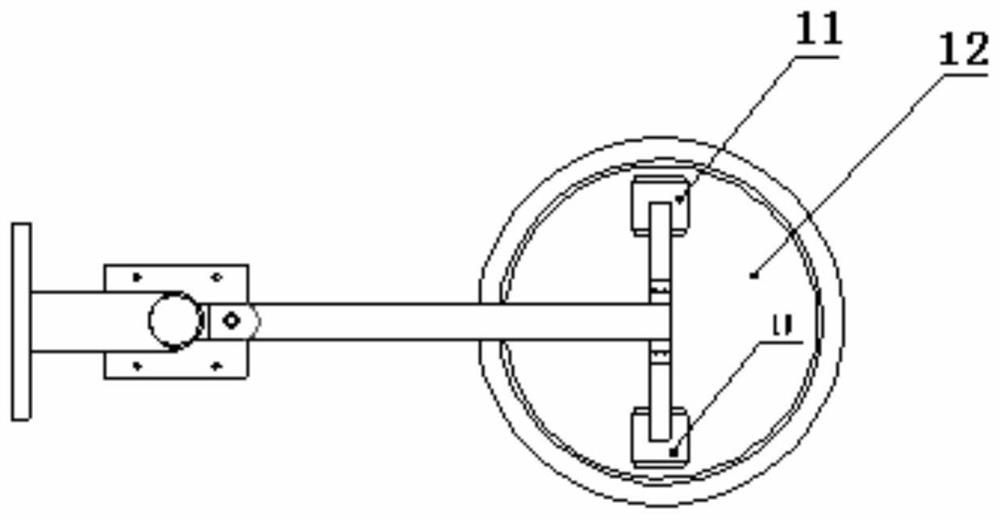

[0019] This embodiment is a device for online detection of the feeding speed of a primary hopper, including a mounting bracket 2, a supporting beam 12, a structured light scanner 11, a camera 10 and a connecting support plate. The installation bracket is fixed on the side of the primary hopper 13 through the installation base 16, anchor bolts 18 and connecting nuts 17, and a support beam 12 is installed on the upper side surface of the installation bracket 2 by connecting a support plate, and the support beam The centerline of the centerline is perpendicular to the centerline of the mounting bracket. Both the camera 10 and the structured light scanner 11 are fixed on the lower surface of the cantilever end of the support beam 12 through a mounting plate, and are respectively located at two ends of the mounting plate. The explosion-proof control box 1 is fixed on the outer surface of the mounting bracket. One end of the power line 7 and the data line 8 communicate with the cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com