Preparation method of polyving akohol nanofiber

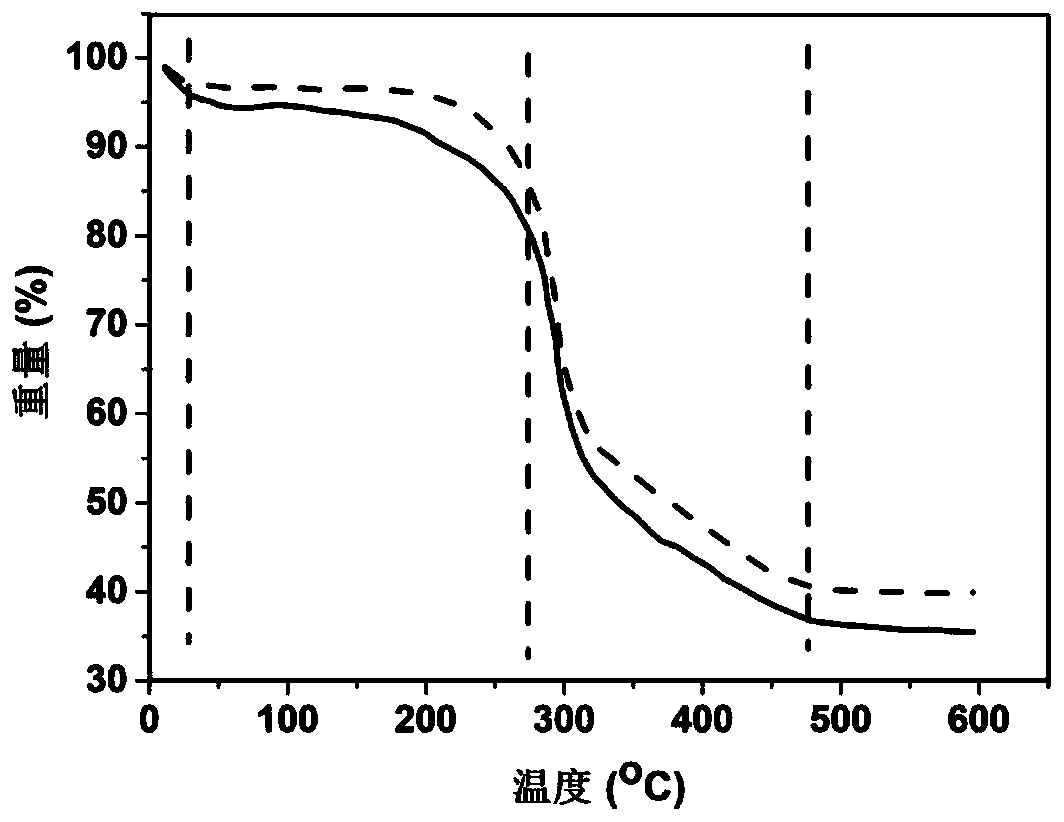

A technology of nanofibers and polyvinyl alcohol, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of long synthesis time of polyvinyl alcohol spinning stock solution, high solubility requirements, and limited development, and achieve excellent Sewage treatment performance, simple processing method, better thermal stability and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in combination with specific embodiments.

[0014] 10g of polyvinyl alcohol powder and 3g of potassium persulfate were added to 87g of water, and stirred at low temperatures of 30, 40, 50 and 60°C for 1 hour respectively to complete the preparation of polyvinyl alcohol spinning stock solution under different synthesis temperature conditions.

[0015] 10 g of polyvinyl alcohol powder was added to 90 g of water, and stirred at a high temperature of 80° C. for 1 hour to complete the preparation of the polyvinyl alcohol spinning stock solution.

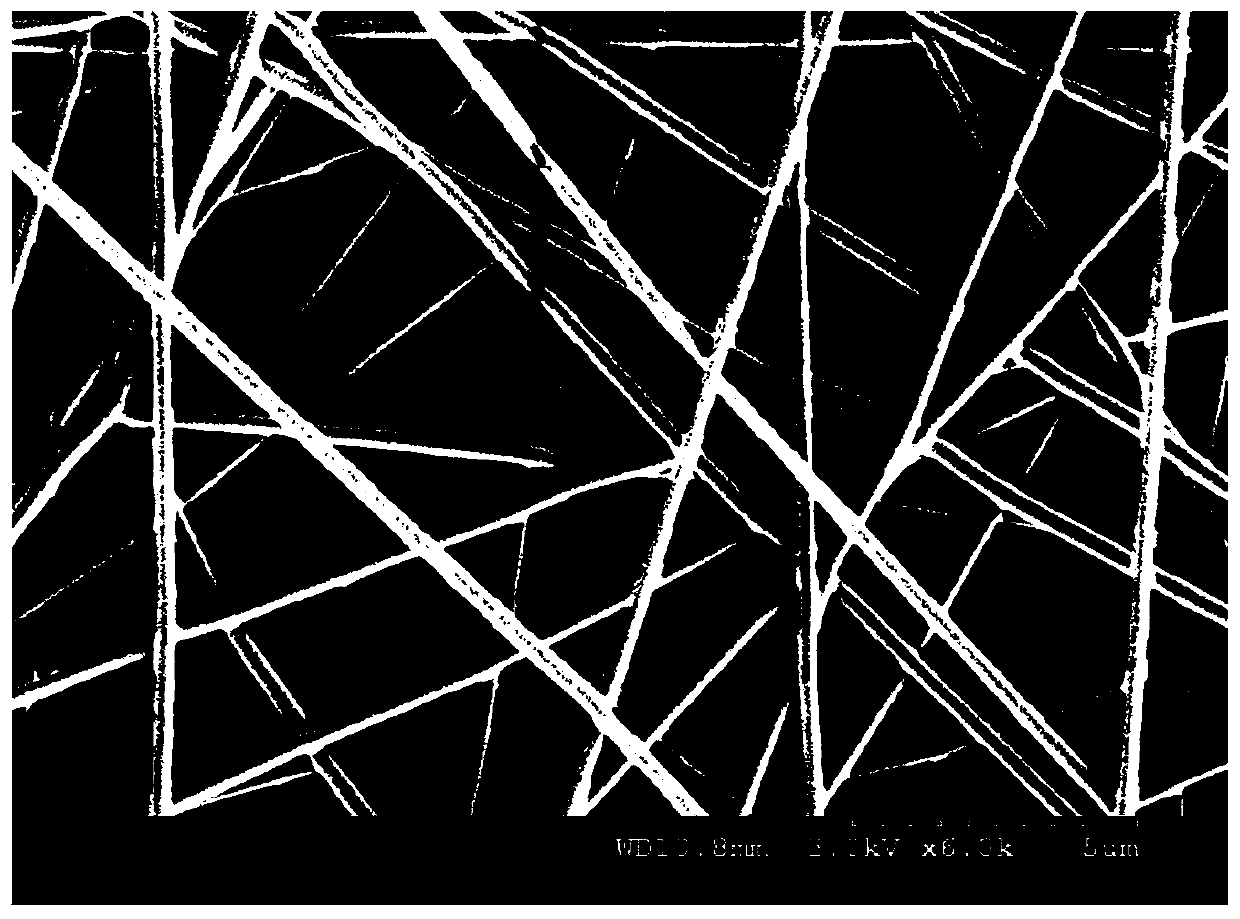

[0016] The synthesized polyvinyl alcohol spinning stock solution was injected into the syringe, and the electrospinning method was used to prepare polyvinyl alcohol nanofibers under the conditions of extrusion rate 0.5mL / hour and spinning voltage 20kV.

[0017] The prepared polyvinyl alcohol nanofibers were tested for fineness (diameter), and the results are listed in Table 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com