Chloride-free coagulating early strength agent for oil well cement and preparation method and application of agent

An oil well cement, coagulation-promoting and early-strength technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of cement stone strength decline, etc., and achieve the effect of easy control and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

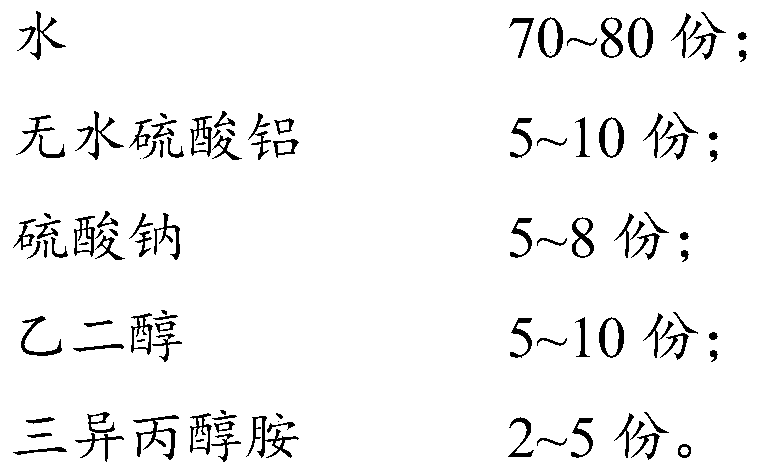

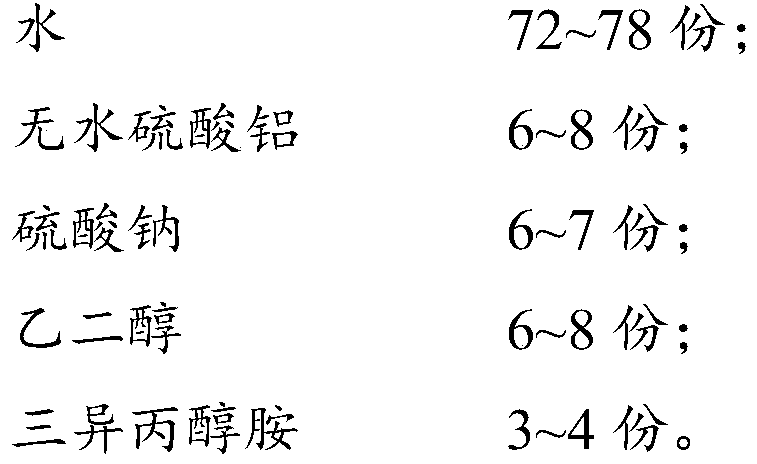

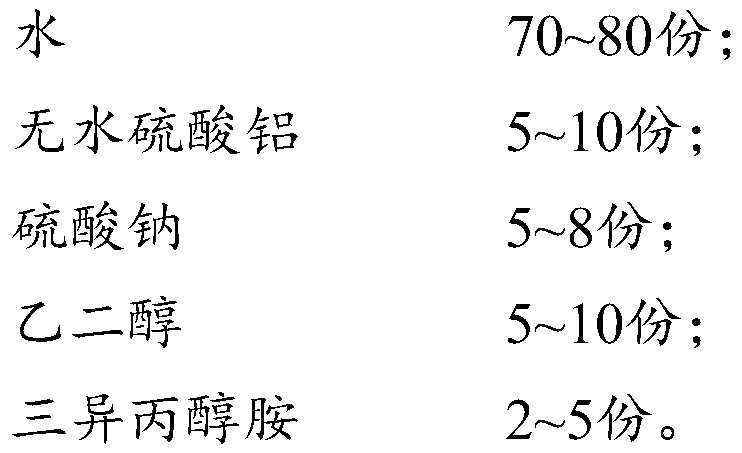

[0026] The present invention provides a preparation method of the chlorine-free coagulation accelerator accelerator for oil well cement described in the above technical scheme, comprising the following steps:

[0027] Anhydrous aluminum sulfate, sodium sulfate, ethylene glycol and triisopropanolamine are dissolved in water to obtain a chlorine-free coagulation accelerator for oil well cement.

[0028] The present invention preferably dissolves under stirring conditions, and the stirring speed is preferably 100 to 200r / min, more preferably 150r / min; the present invention preferably mixes anhydrous aluminum sulfate, sodium sulfate, ethylene glycol and triisopropanol The amines are sequentially added into water for dissolution, each substance is completely dissolved and stirred evenly, and then the next substance is added; in a specific embodiment of the present invention, each substance is preferably stirred for 0.5-1 hour before adding the next substance.

[0029] In the presen...

Embodiment 1

[0035] The composition of the chlorine-free coagulation accelerator for oil well cement is: 75g of water, 6g of anhydrous aluminum sulfate, 5g of sodium sulfate, 6g of ethylene glycol, and 2g of triisopropanolamine;

[0036] Anhydrous aluminum sulfate, sodium sulfate, ethylene glycol and triisopropanolamine are dissolved in water in sequence and mixed evenly to obtain the chlorine-free coagulation accelerator accelerator for oil well cement.

[0037] performance testing

[0038] The performance tests of the chlorine-free coagulation accelerator accelerator for oil well cement obtained in Example 1 were carried out under low temperature conditions and high temperature conditions respectively.

[0039] (1) Low temperature (45°C) performance test:

[0040] The high temperature resistant cement slurry system consists of G grade cement, water, external admixture (quartz sand), fluid loss reducer (commercially available) and dispersant (commercially available), of which G grade cem...

Embodiment 2

[0059] The composition of the chlorine-free coagulation accelerator for oil well cement is: 80g of water, 7g of anhydrous aluminum sulfate, 7g of sodium sulfate, 8g of ethylene glycol, and 5g of triisopropanolamine;

[0060] Anhydrous aluminum sulfate, sodium sulfate, ethylene glycol and triisopropanolamine are dissolved in water in sequence and mixed evenly to obtain the chlorine-free coagulation accelerator accelerator for oil well cement.

[0061] According to the method in Example 1, the obtained oil well cement chlorine-free coagulation accelerator accelerator is tested for performance under low temperature conditions, and the obtained results are shown in Table 3;

[0062] Table 3 Example 2 Effect of chlorine-free coagulation accelerator accelerator on high temperature resistant cement slurry system for oil well cement

[0063]

[0064] According to the method in Example 1, the obtained oil well cement chlorine-free coagulation accelerator accelerator was tested for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com