Composition containing phosphate and application thereof

A composition and phosphate technology, applied in the field of polymer additives, can solve the problem of not finding plastic additives, and achieve the effects of reduced warpage and good warpage prevention effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of embodiment 1 anti-warping composition

[0025] The raw materials are mixed according to the components and weight percentage of the anti-warping composition, and then fully stirred evenly to obtain the anti-warping compositions A1 to A8.

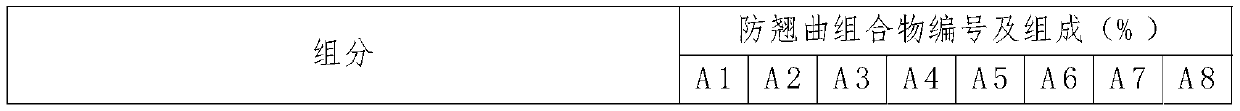

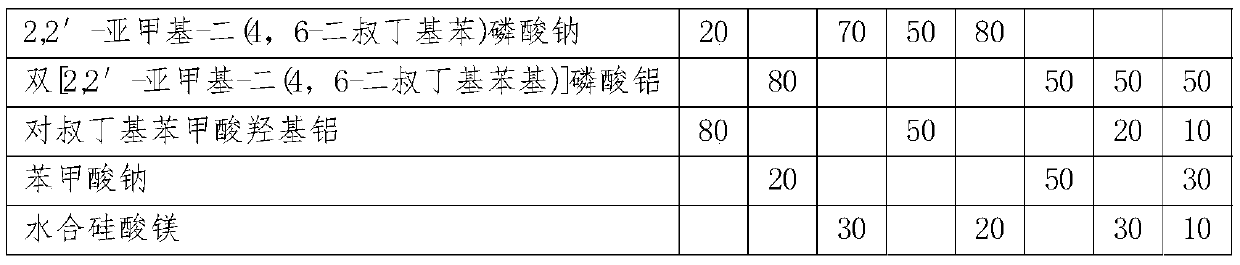

[0026] The composition of table 1 anti-warping composition

[0027]

[0028]

Embodiment 2

[0029] Example 2 Polymer with low warpage

[0030] The preparation method of the polymer is:

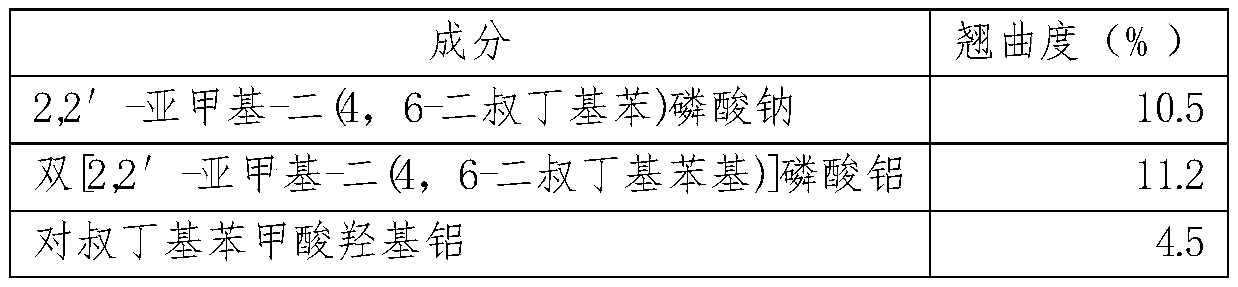

[0031] Five single components of 2,2'-methylene-bis(4,6-di-tert-butylphenyl)sodium phosphate, bis[2,2'-methylene-bis(4,6-di-tert-butyl phenyl)]aluminum phosphate, hydroxyaluminum p-tert-butylbenzoate, sodium benzoate and hydrated magnesium silicate, blank polypropylene and the above-mentioned anti-warping compositions A1-A8 are mixed with polypropylene respectively, one-component and anti-warping compositions The warping composition was added in an amount of 0.1% by weight of the polypropylene, and the blank polypropylene had no additions. Then melt granulation is carried out with twin-screw extruder respectively to obtain polypropylene pellets respectively.

[0032] The measurement method of warpage is:

[0033] 600g of polypropylene pellets containing a single component, polypropylene pellets without any ingredients, and polypropylene pellets containing the above-mentioned A1-A8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com