Grouting closestool mold capable of achieving precise and rapid mold closing and opening

A mold and rapid technology, applied in the direction of manufacturing tools, unloading devices, auxiliary molding equipment, etc., can solve the problems of manual operation accuracy cannot be guaranteed, high defective product rate, poor mold removal operability, etc., to achieve simple and accurate mold closing effect , The structural design is novel and ingenious, and the alignment is fast and accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with specific embodiment, this case is described in further detail.

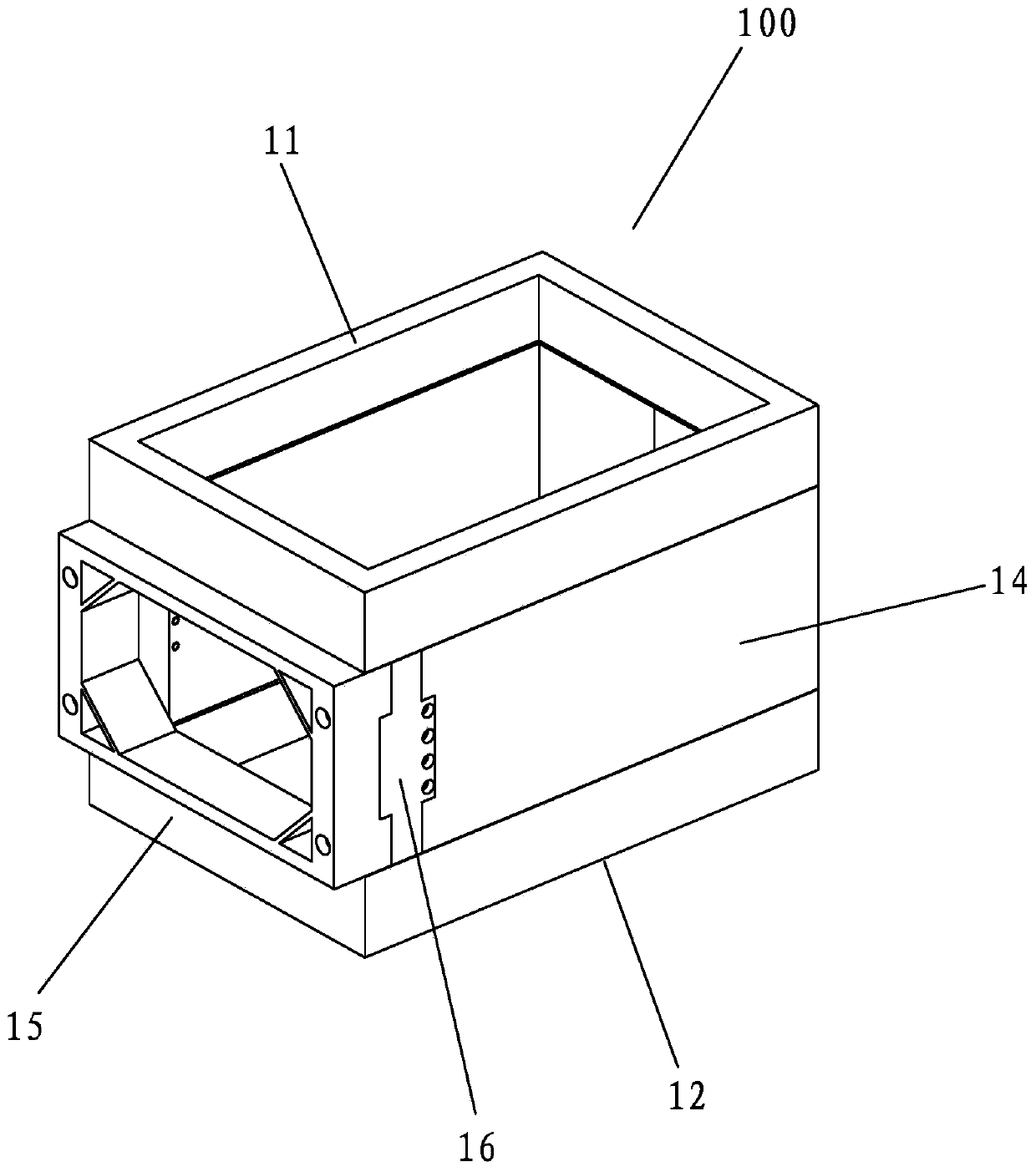

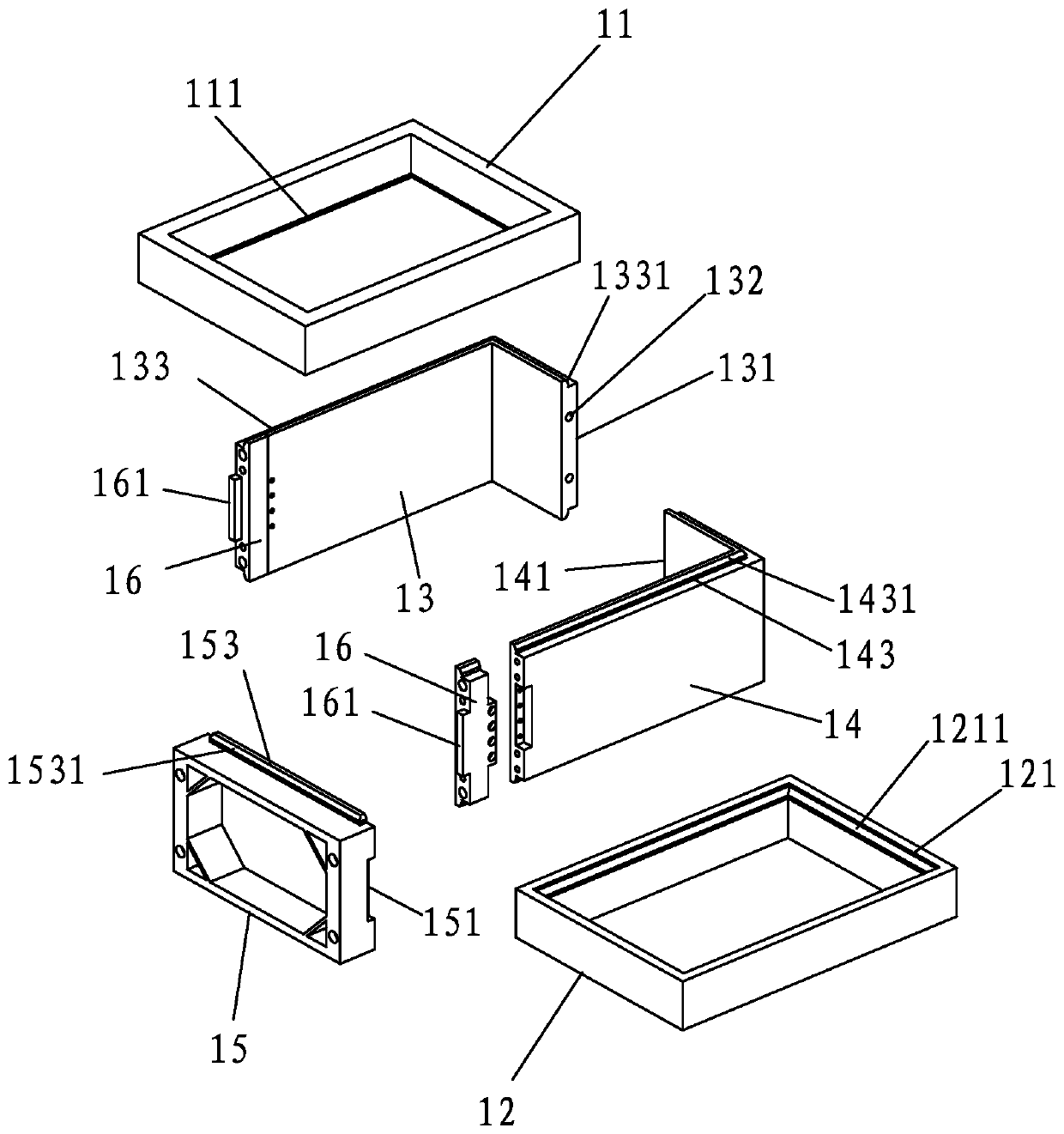

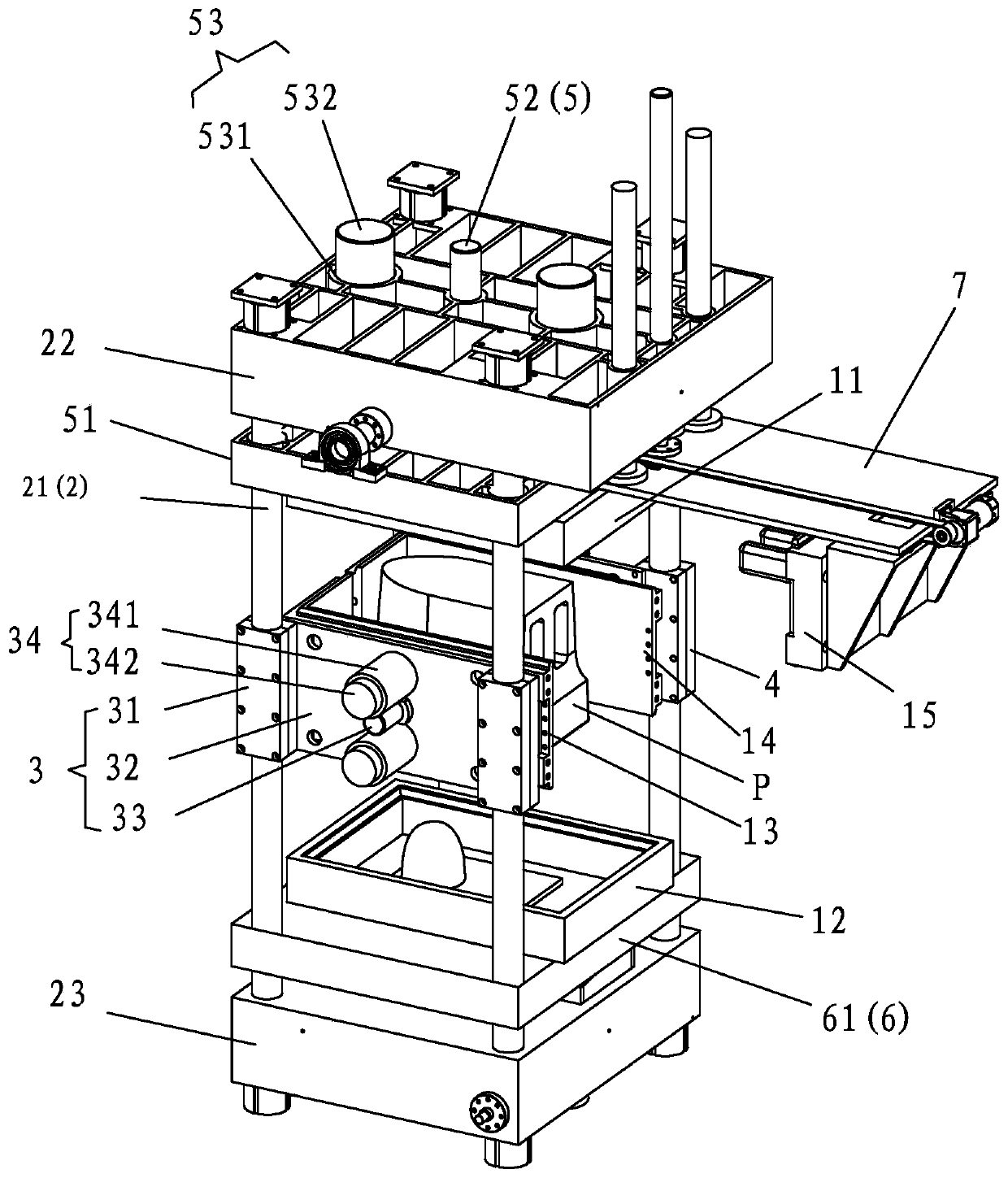

[0069] This case involves a grouting toilet mold that can be closed and opened accurately and quickly, such as Figure 1-4 As shown, a mold body 100 is included, and the mold body 100 is composed of several templates, specifically including an upper cover plate 11 , a lower cover plate 12 , a left side plate 13 , a right side plate 14 and a rear side plate 15 . These templates are molded together to form a quadrilateral mold body, and the inner side of each template has a corresponding model structure (not shown in the figure) corresponding to the toilet embryo body.

[0070] The left side plate 13 and the right side plate 14 are all L-shaped structures, and the left side plate 13 and the right side plate 14 are molded left and right in a butt joint mode to form a door-shaped structure, and wherein the butt joints 131 / 141 are provided with There is an active connection mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com