Numerical control gantry needle groove milling machine

A needle groove milling machine, gantry technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment and other directions, can solve problems such as large limitations, inconsistent processing depth, lack of theoretical basis, etc., to achieve high safety, accurate indexing, Solve the effect of different processing depths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

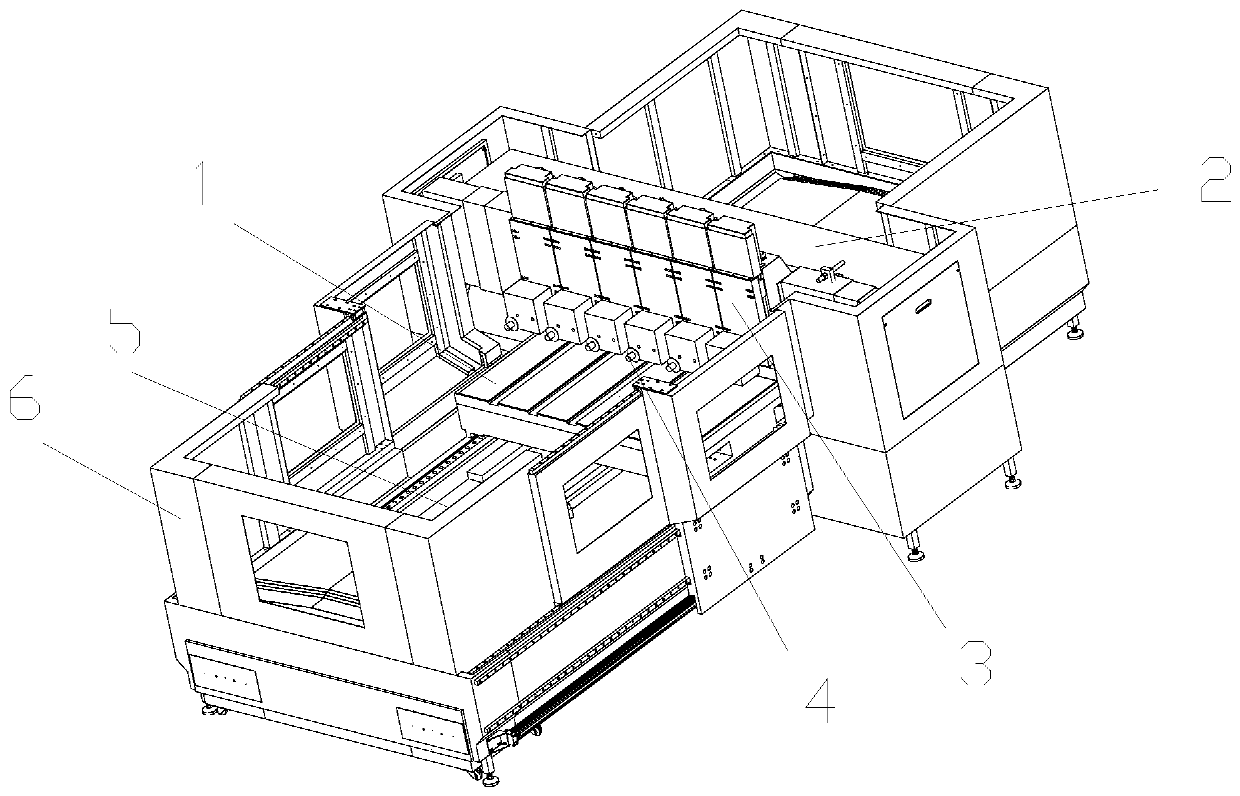

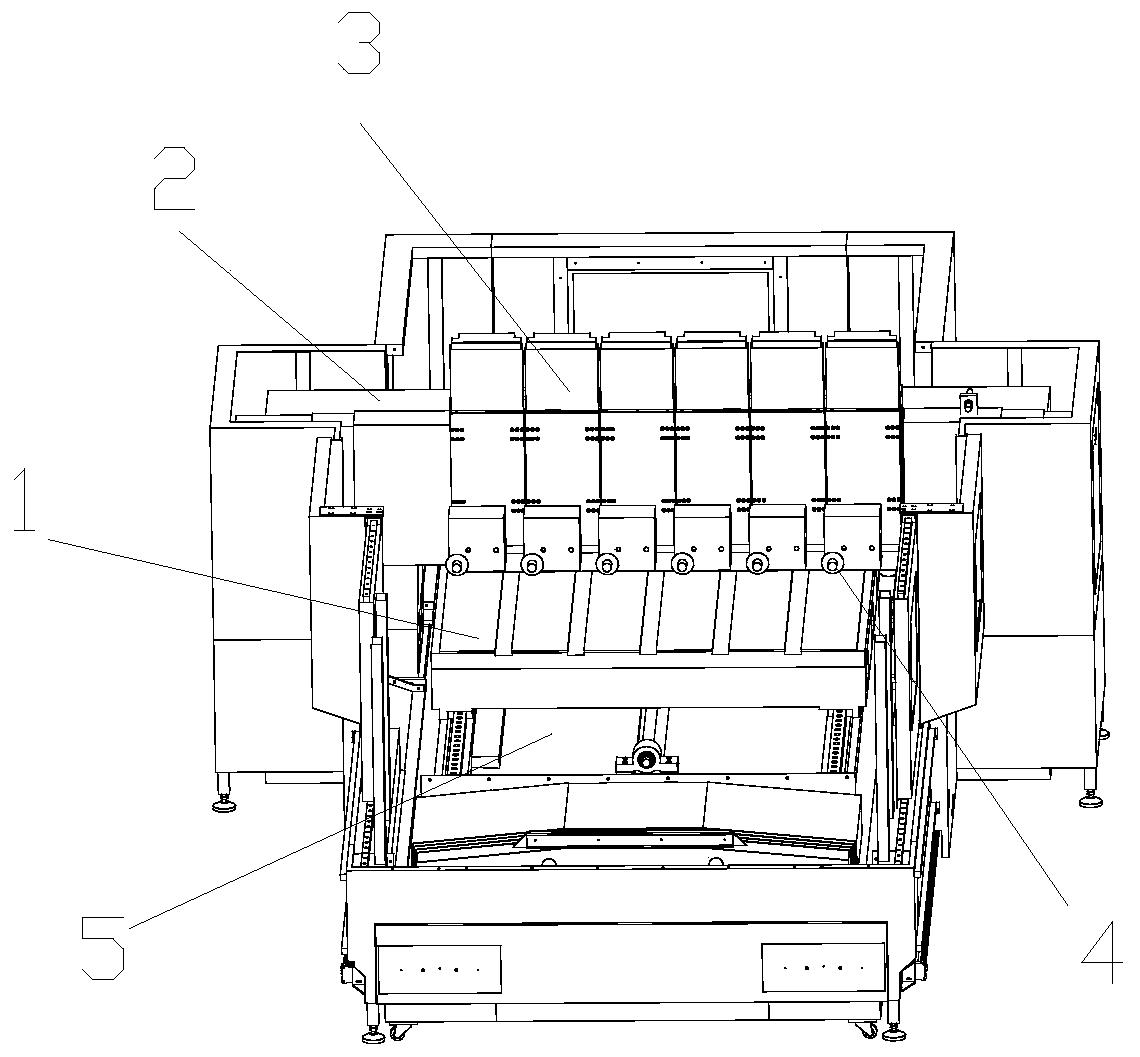

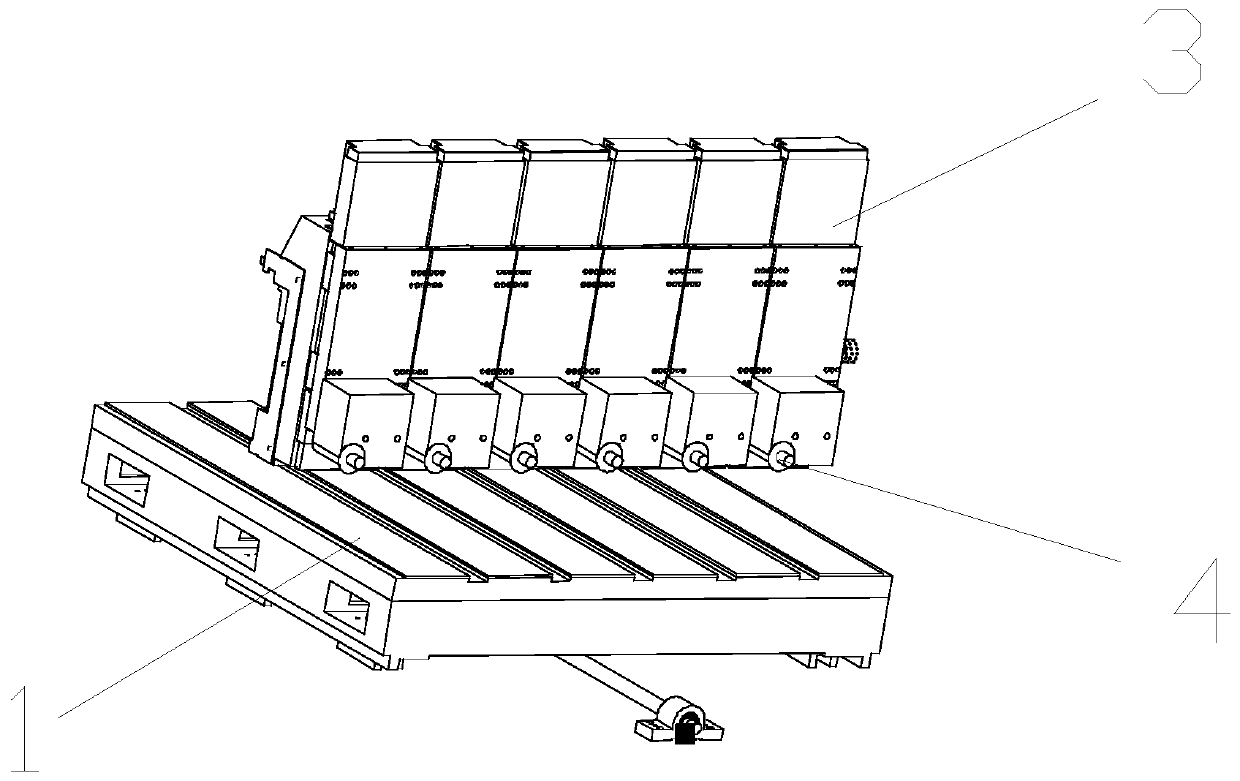

[0023] Embodiment 1 refers to Figure 1-6 A CNC gantry needle slot milling machine includes a milling machine and a milling head. The milling machine is provided with a plurality of milling heads 3 for independent tool setting, and each milling head is provided with a milling cutter 4 .

[0024] A numerically controlled gantry needle slot milling machine, in which a plurality of milling heads 3 move up and down synchronously on the Z axis through connecting pieces, and the milling cutters of the milling heads are provided with an independent fine-tuning structure for tool setting.

[0025] A numerically controlled gantry needle groove milling machine, a processing platform 1 of the milling machine is provided with a grating ruler for measuring the moving distance of a milling cutter, and the grating ruler is connected to a central control system.

[0026] A numerical control gantry needle slot milling machine, with 3 to 6 milling heads.

[0027] A CNC gantry needle groove mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com