Silica gel make-up method

A technology of silica gel and mold base, which is used in packaging cosmetics, cosmetic containers, cosmetic powder containers, etc., can solve problems such as difficult color repair, and achieve the effects of not easy cracking and falling off, cost saving, and strong adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

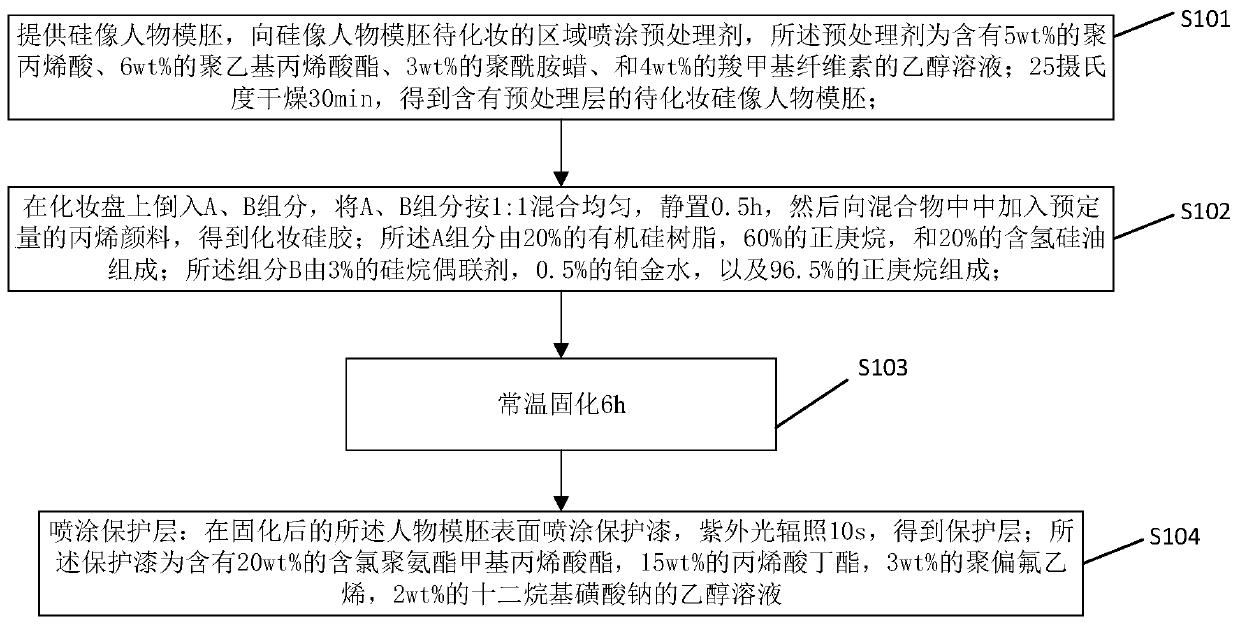

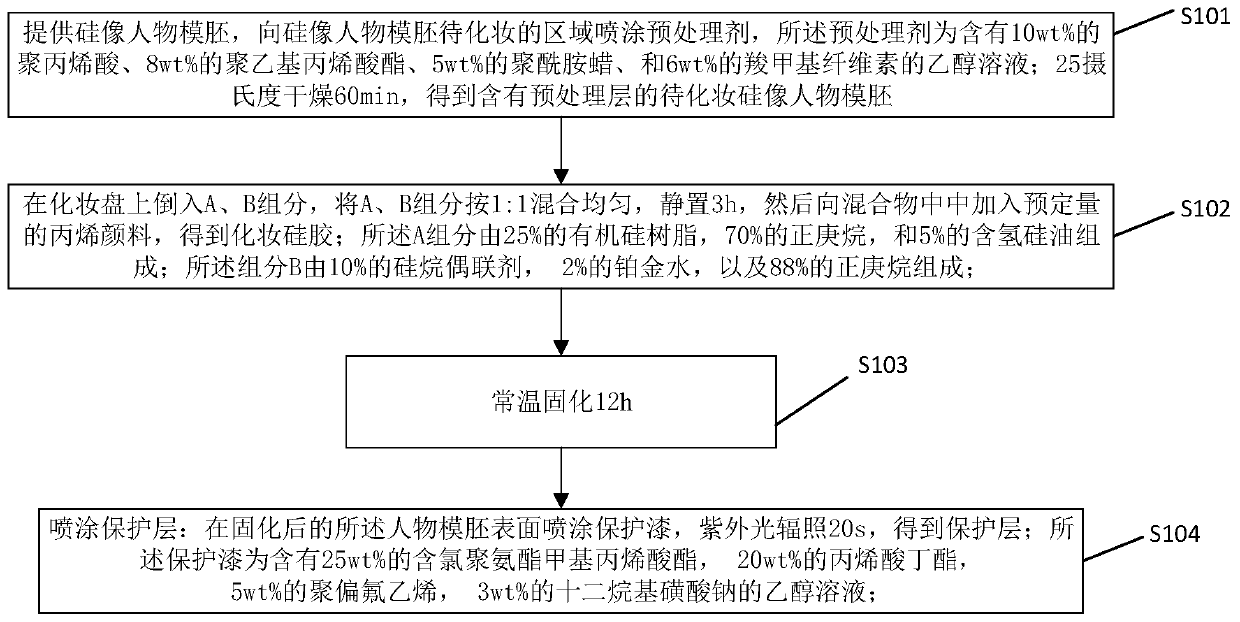

[0028] The present invention provides four embodiments of a silicone makeup method, in order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the present invention more obvious Easy to understand, below in conjunction with accompanying drawing, technical scheme among the present invention is described in further detail:

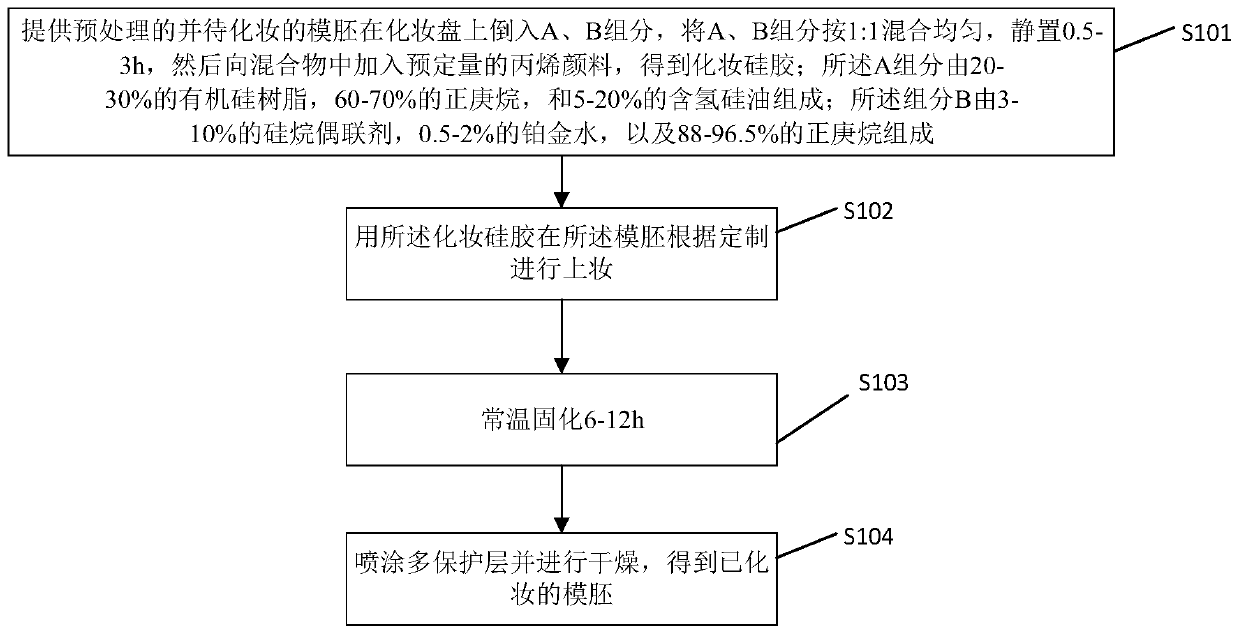

[0029] The present invention firstly provides a first embodiment of a method for applying makeup on silica gel, as figure 1 As shown, a silicone makeup method, especially a makeup method based on a highly simulated robot, includes:

[0030] Step 1 S101, provide the pretreated mold base to be made up and pour A and B components on the make-up tray, mix A and B components evenly at a ratio of 1:1, let stand for 0.5-3h, and then add to the mixture A predetermined amount of acrylic paint is used to obtain cosmetic silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com