Magnetron antenna assembly

A technology for antenna components and magnetrons, applied in magnetrons, antenna supports/mounting devices, electrical components, etc., can solve problems such as increased costs, low output efficiency, unfavorable test processing, etc., to reduce discharge and improve The effect of service life and reducing the probability of sparking and generating electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0028] The invention provides a magnetron antenna assembly, the working principle of which is to optimize the design of the antenna and the output window, so that the magnetron antenna assembly has good transmission efficiency, and also reduces the requirements of the magnetron antenna assembly on the excitation cavity , to achieve the purpose of improving the transmission efficiency of microwave coupling, reducing the cost and reducing the matching degree between the antenna and the excitation cavity.

[0029] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

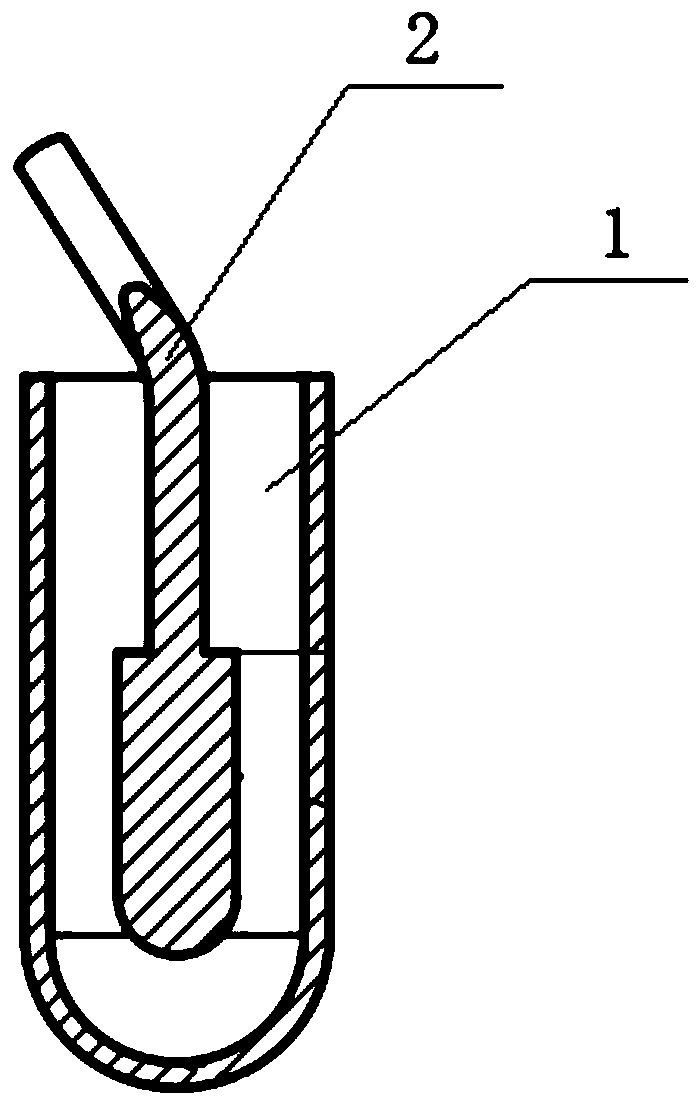

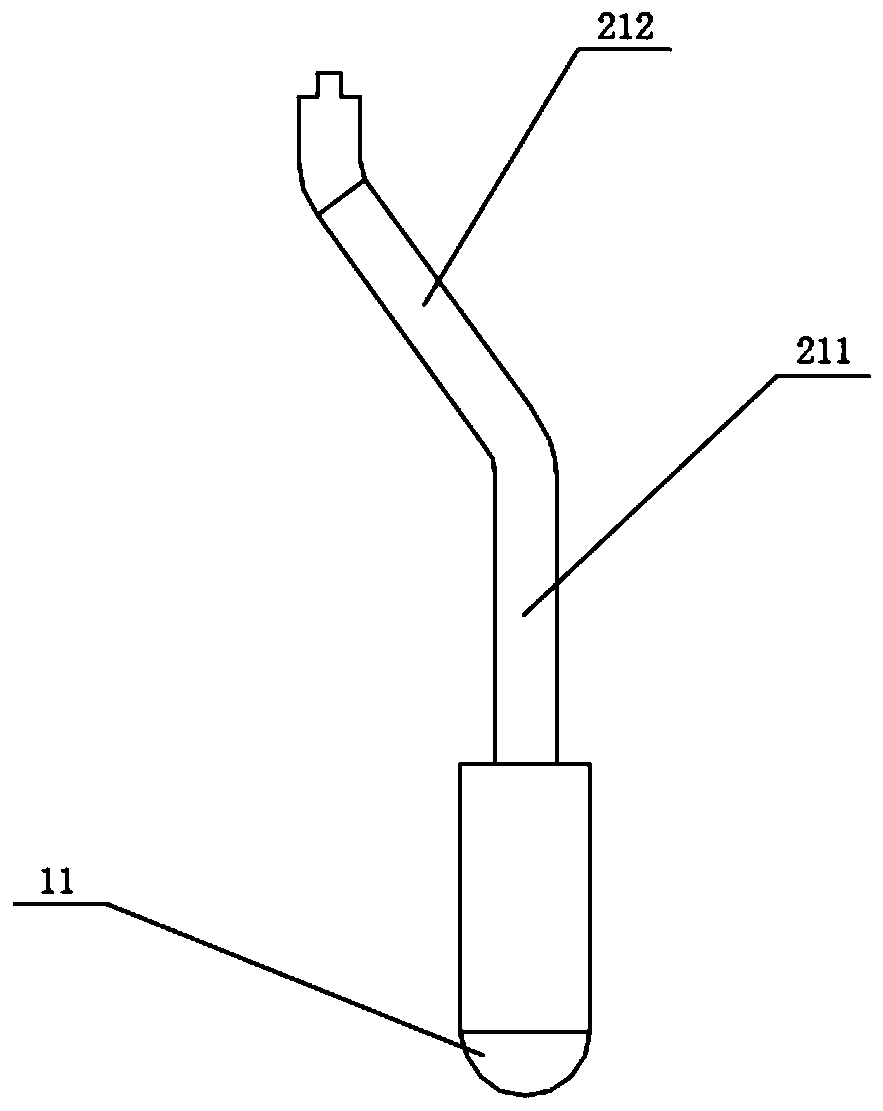

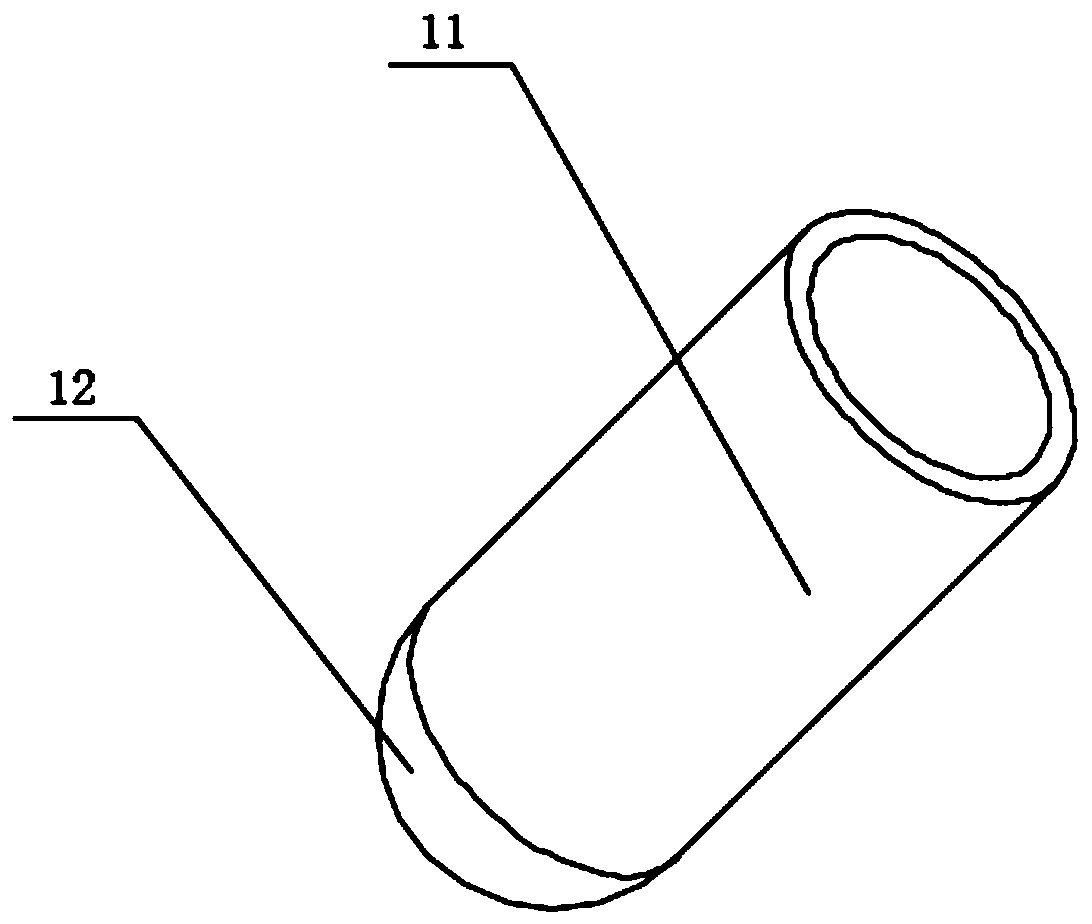

[0030] like Figure 1-Figure 3 As shown, a magnetron antenna assembly includes an output window 1 made of ceramics set on the excitation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com