A whole-process slippage calculation method for an assembly type shear connector

A calculation method and assembly technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems affecting calculation accuracy and structural safety, calculation errors of composite beam stiffness and bearing capacity, and small slip calculation results, etc. problems, to achieve the effect of ensuring calculation accuracy and structural safety, correct calculation, and accurate slip calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Referring to Tables 3-7, 3-8, 3, 3-10, a calculation method for slippage in the whole process of fabricated shear connectors, the calculation method includes the following steps:

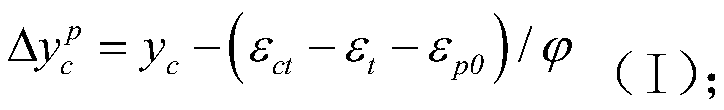

[0051] S1, determine the geometric parameters of the assembled composite beam section, the analytical formula of the plate height is:

[0052]

[0053] where: ε ct Calculate the nominal tensile strain for concrete; ε p0 is the precompressive strain at the edge of the concrete slab; ε t is the ultimate tensile strain of concrete;

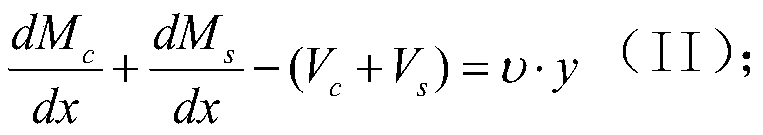

[0054] S2. According to the balance relationship of the internal force of the composite beam in the micro-segment, the static balance equation of the concrete slab and the steel beam in the micro-segment is established:

[0055]

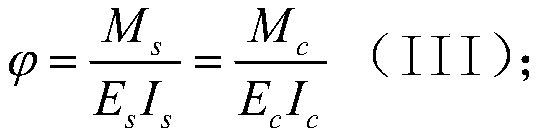

[0056] S3, establish the curvature calculation equation of steel truss beam and concrete slab:

[0057]

[0058] S4, establish the slip-shear stress relationship calculation formula:

[0059]

[0060] S5, the slip-load dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com