Self-tensile strength measuring mold of flame-spraying nylon coating layer

A technology of flame spraying and tensile strength, which is applied in the direction of applying stable tension/pressure to test the strength of materials and the preparation of test samples. It can solve the problems of easy cracking of the coating, poor cohesion of the coating, and poor adhesion of the coating. Good and other questions, to achieve accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some of these specific details. The following description of the embodiments is only to provide a better understanding of the present invention by showing examples of the present invention.

[0016] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

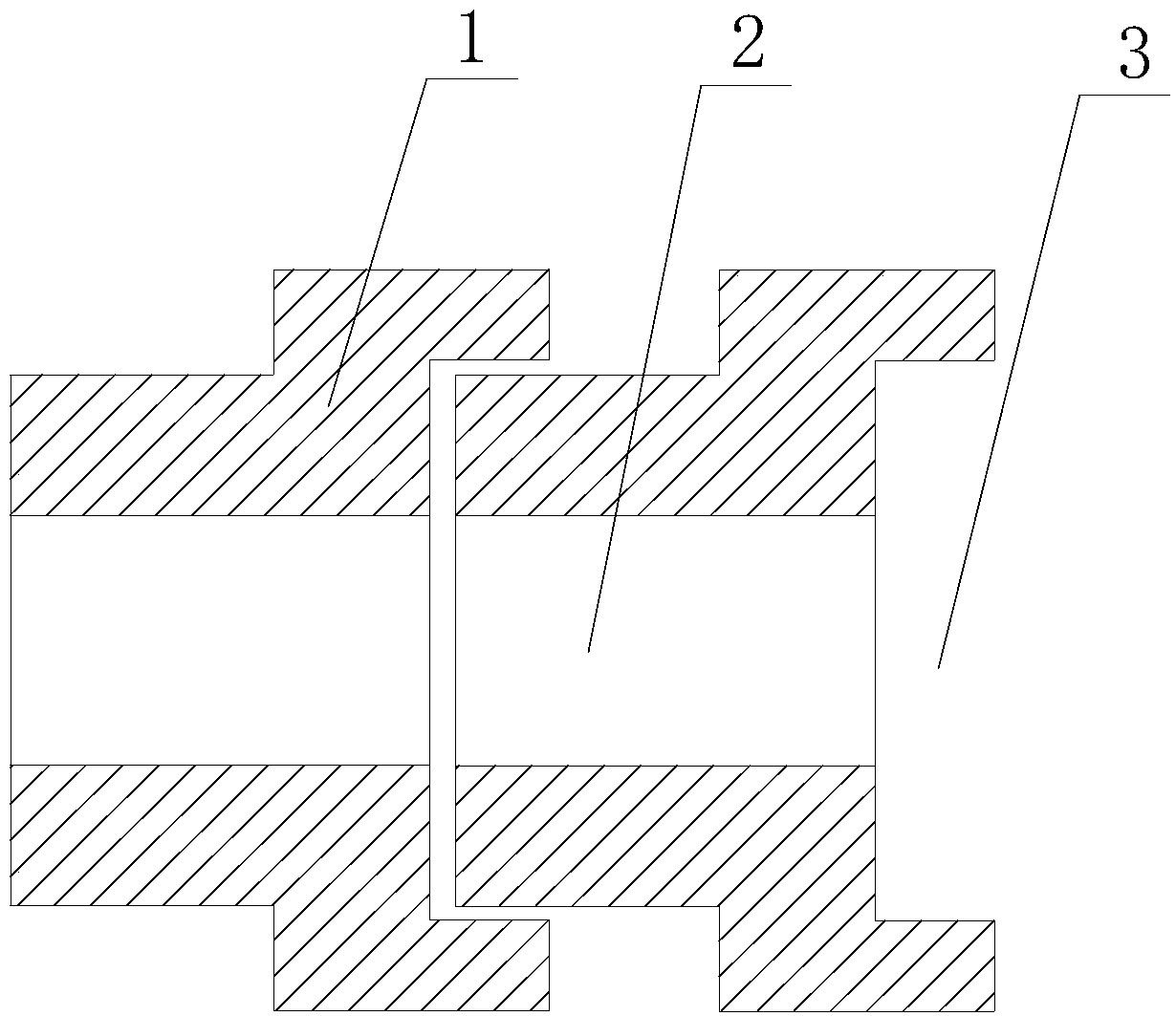

[0017] Such as figure 1 Shown, the present invention provides a kind of self-tensile strength measurement mold of flame spraying nylon layer, comprises mold body, and through hole is arranged in the middle of described mold body; One end of described mold body is a cylinder, and the other end of described mold body One end is provided with a cylindrical boss; the cylindrical boss is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com