Center adjustment method of bi-directional thrust bearing for shaft seal and main pump positioning in nuclear power plant

A two-way thrust bearing and center adjustment technology, applied in pumps, pump components, non-variable pumps, etc., can solve the problems of radial pad wear, narrow measurement space, and large vibration value of the main pump, so as to prevent inaccurate values , Simple operation, accurate gap measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] When the shaft seal main pump is assembled for the first time in the factory, when the center position of the two-way thrust bearing is not determined, the upper pump shaft is pushed to the center, and the upper pump shaft is rotated, according to the actual reading of the dial gauge on the upper pump shaft on the inner wall of the seal , to adjust the position of the two-way thrust bearing in the center, so that the two-way thrust bearing meets the operating requirements.

[0032] A method for adjusting the center of a shaft seal nuclear main pump in a nuclear power plant for positioning a two-way thrust bearing, comprising the following steps:

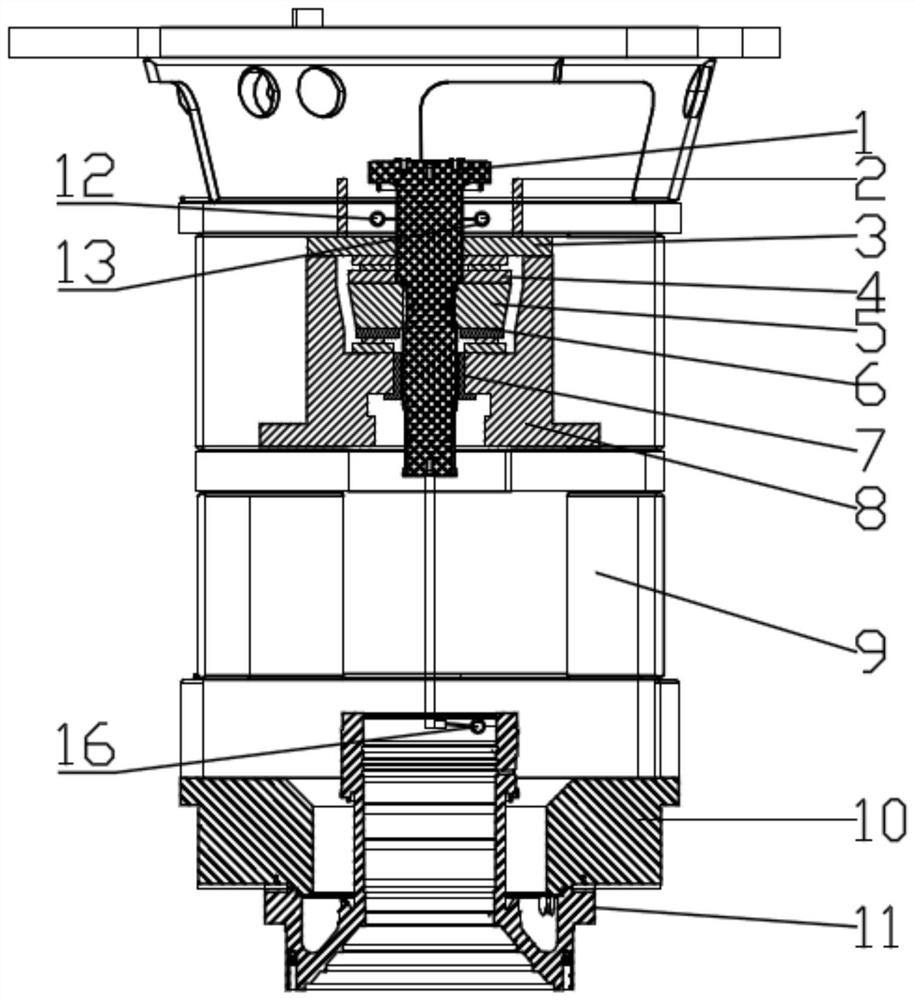

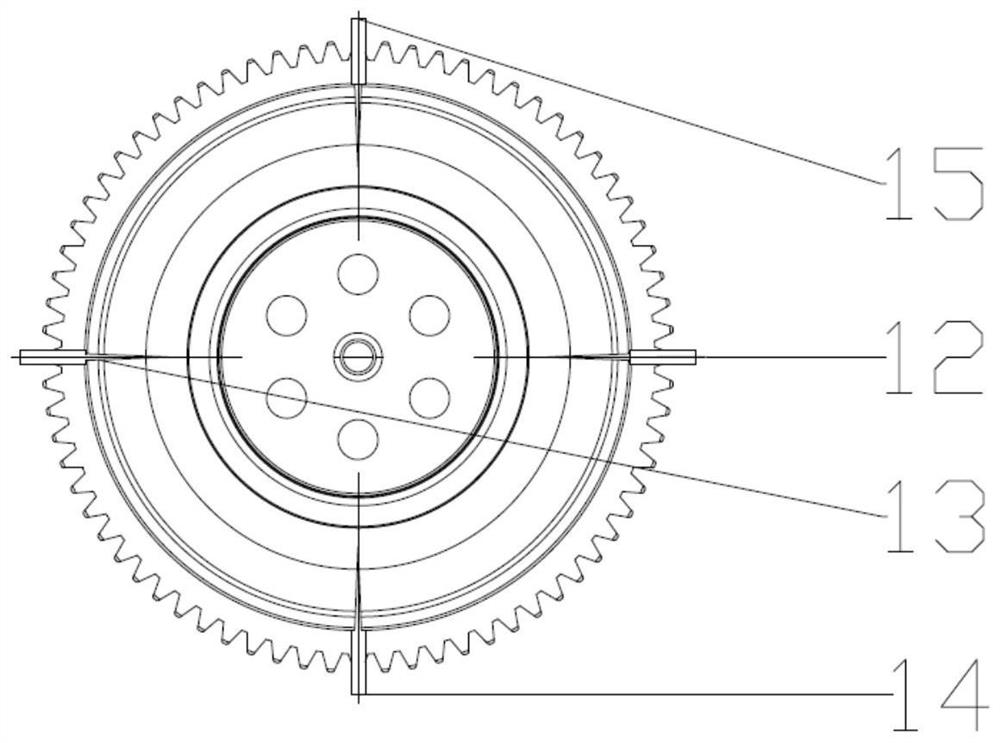

[0033] 1) Complete the assembly of the thrust bearing: such as figure 1 As shown, the pump shaft 1, diversion standpipe 2, bearing chamber cover 3, main thrust pad 4, thrust disc 5, auxiliary thrust pad 6, radial pad 7, and bearing chamber 8 are assembled according to the drawings, and the Put the thrust bearing into the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com