Non-welding connection structure of fan tower platform

A technology for connecting structures and fan towers, applied in the installation/support of wind turbine configuration, wind power generation, etc., can solve the problem of not many tower platform solutions, reduce operation and maintenance risks, reduce platform reliability, and improve fatigue performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

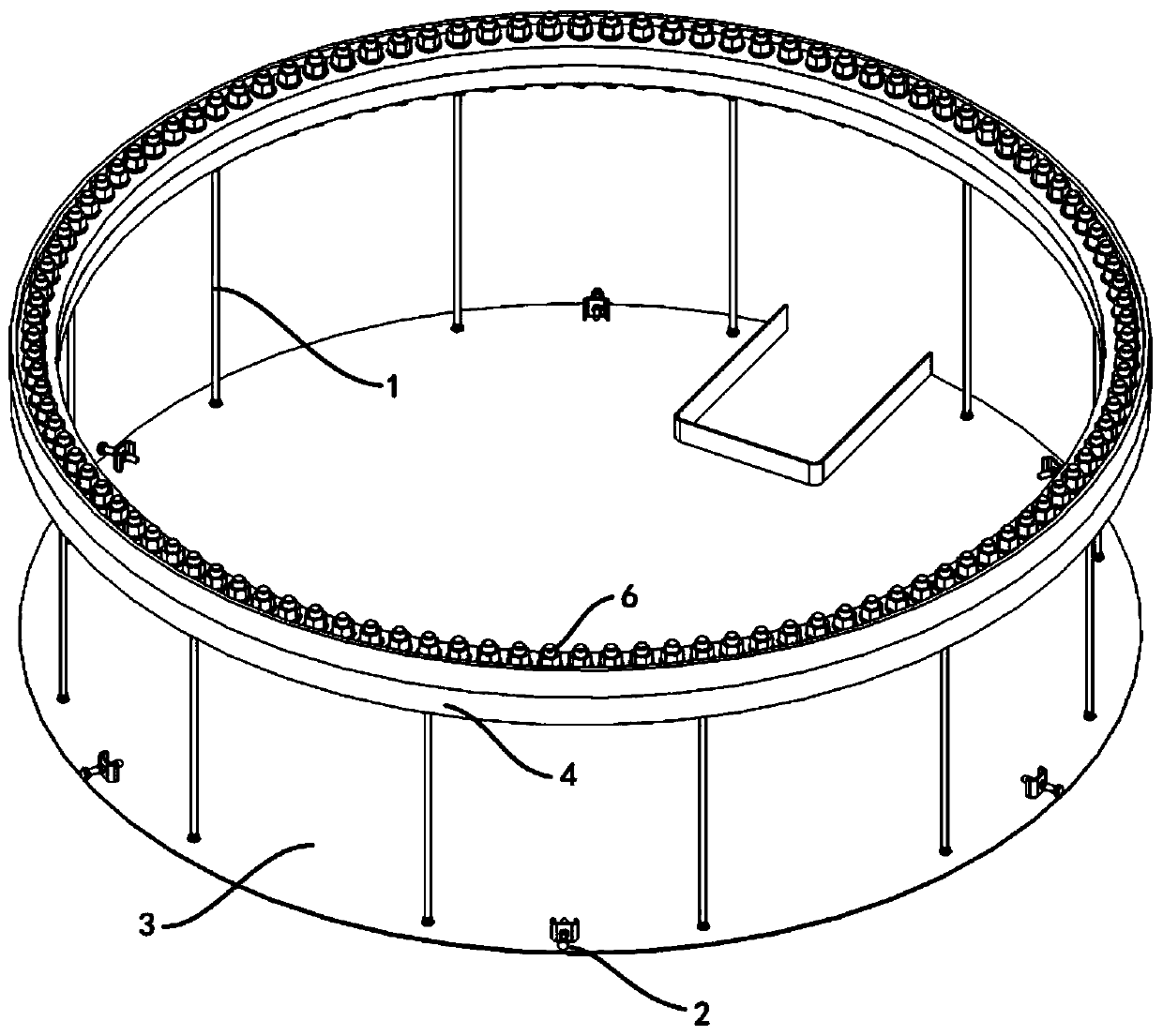

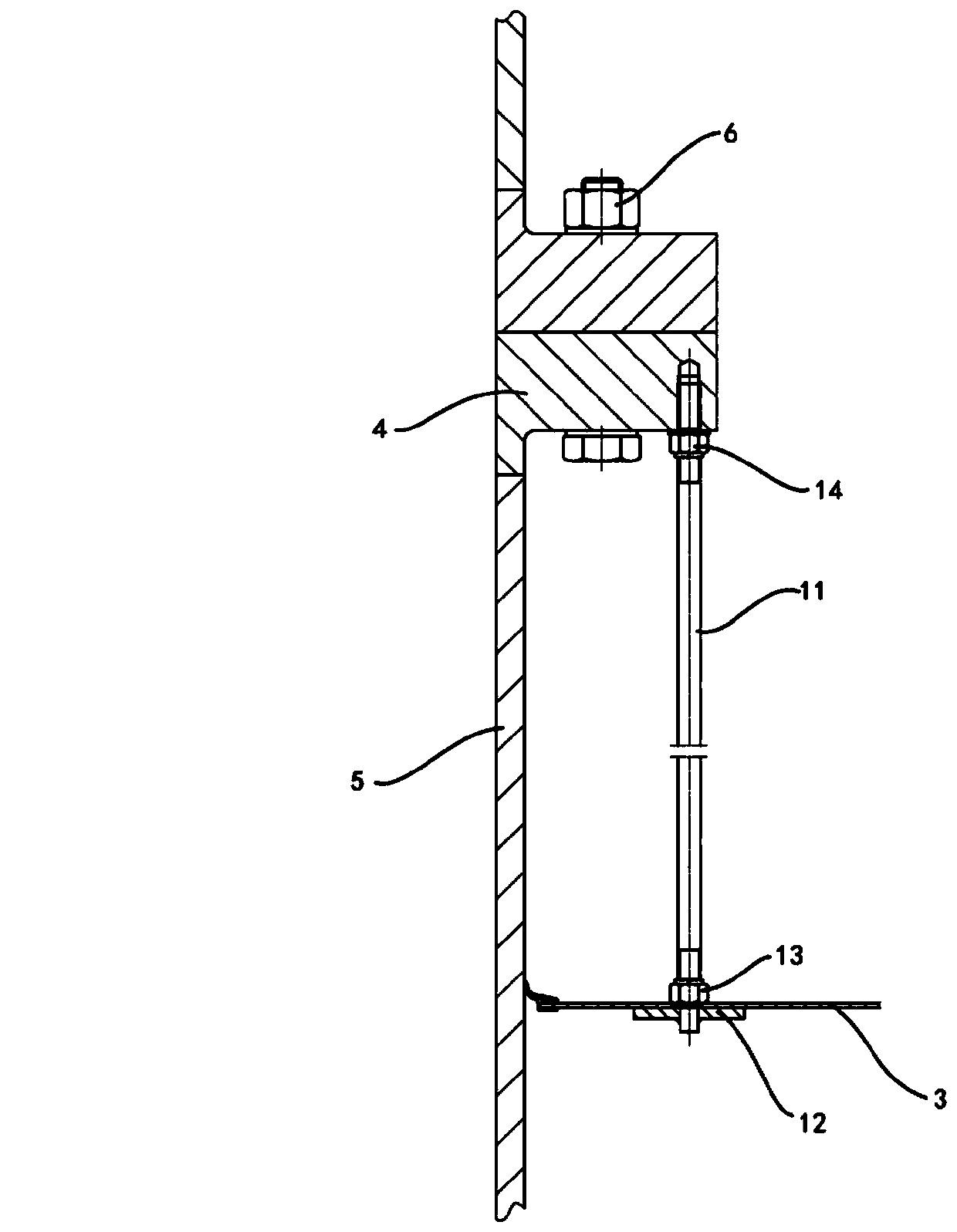

[0024] Such as Figure 1 to Figure 4 As shown, the non-welded connection structure of the wind turbine tower platform provided by this embodiment adopts a suspended platform structure, including a suspension assembly 1 and an anti-swing support assembly 2; there are multiple sets of suspension assemblies 1 (the specific number depends on determined by the actual structure of the platform and the rated load-bearing capacity of the platform), and distributed along the circumferential direction of the tower platform 3; The circumferential distribution; the suspension assembly 1 is composed of a suspension screw 11, a welded bearing plate 12, a lower lock nut 13 and an upper lock nut 14, and the inner end surface of the tower flange 4 of the fan tower is provided with a The threaded hole of the threaded connection of the suspension screw 11 can be processed into a through hole or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com