Regeneration technology of hydrogen-generation adsorbent

A technology of adsorbent regeneration and adsorbent, which is applied in the field of hydrogen production adsorbent regeneration process, can solve the problems of activated carbon adsorbent regeneration, high safety risks, long time for changing adsorbent, etc., and achieve the effect of saving regeneration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

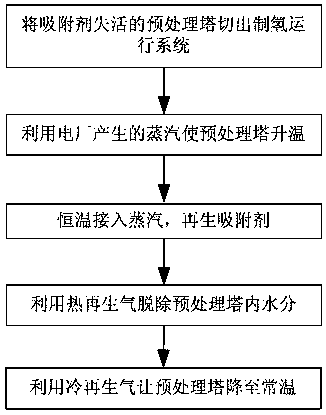

[0045] Please refer to figure 1 as shown, figure 1 It is a flow chart of hydrogen production adsorbent regeneration process. The hydrogen production adsorbent regeneration process of this embodiment includes the following steps:

[0046] (1) The pretreatment tower with deactivated adsorbent is cut out of the hydrogen production operation system, and the other pretreatment towers in the operation system operate normally;

[0047] (2) After the superheated steam generated by the power plant is processed into regeneration steam, it is continuously sent from the top of the pretreatment tower to the tower of the pretreatment tower, and the regeneration steam regenerates the adsorbent in the tower and then flows from the tower of the pretreatment tower Bottom discharge, stop sending regeneration steam after the adsorbent regeneration is qualified;

[0048] (3) The regenerative desorption gas generated by connecting the operation system from the top of the tower, after dehydration...

Embodiment 2

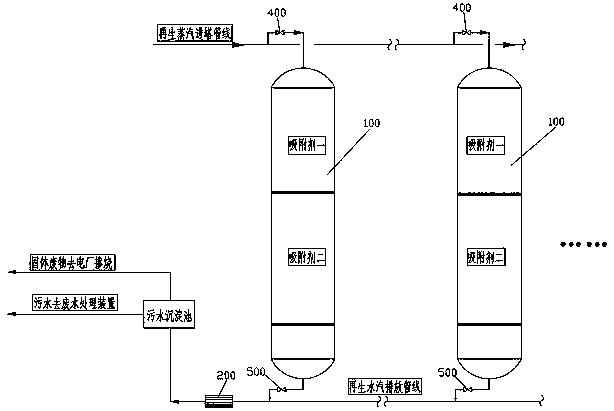

[0057] On the basis of the hydrogen production adsorbent regeneration process disclosed in Embodiment 1, this embodiment discloses a hydrogen production adsorbent regeneration system.

[0058] There are multiple pretreatment towers in the hydrogen production system, and each pretreatment tower is filled with adsorbents. The adsorption efficiency of the adsorbents will decrease after a period of use, and the adsorbents need to be regenerated.

[0059] Such as figure 2 As shown, the hydrogen production adsorbent regeneration system includes:

[0060] The regeneration steam inlet pipeline connected to the tower tops of multiple pretreatment towers 100; the regeneration steam inlet pipeline transports steam at 0.5~0.6Mpa and 240~280°C from the tower top to the tower for adsorbent regeneration;

[0061] A plurality of tower top steam inlet valves 400 corresponding to a plurality of pretreatment towers 100, and a plurality of tower top steam inlet valves 400 are all arranged on th...

Embodiment 3

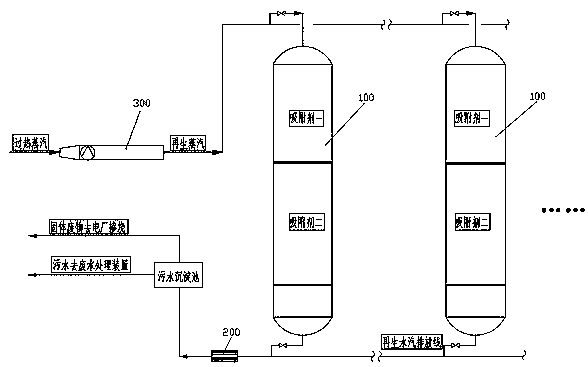

[0078] On the basis of the solutions disclosed in Example 1 and Example 2, this example describes in detail the hydrogen production adsorbent regeneration system and process. This process can realize the regeneration of the adsorbent in the pretreatment tower.

[0079] Temperature swing adsorption is a simple, energy-saving and efficient gas separation and purification technology. It is currently widely used in the pretreatment process of feed gas for pressure swing adsorption hydrogen production units.

[0080] The temperature swing adsorption pretreatment process of oxygen-containing hydrogen production refers to the selective adsorption of tar, naphthalene and other organic impurities in the pretreatment tower filled with activated carbon adsorbent bed through physical adsorption. When approaching or reaching adsorption saturation, it is necessary to regenerate the activated carbon adsorbent to ensure that the activated carbon can be recycled. According to the actual produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com