Moving bottom frame of movable six-axis robot

A six-axis robot and movable technology, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of heavy robot weight, limited effective working range, and reduced robot flexibility, so as to improve structural stability and work position. Easy to adjust and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

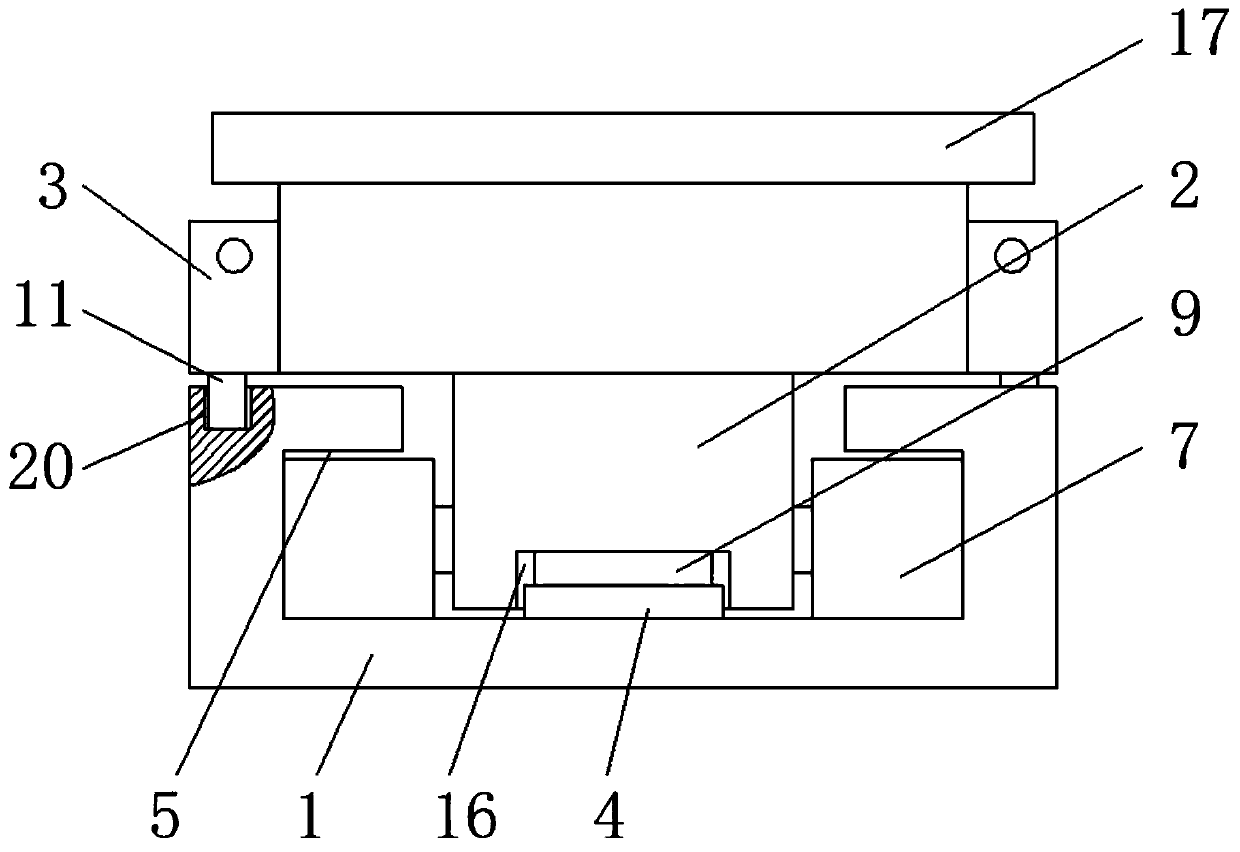

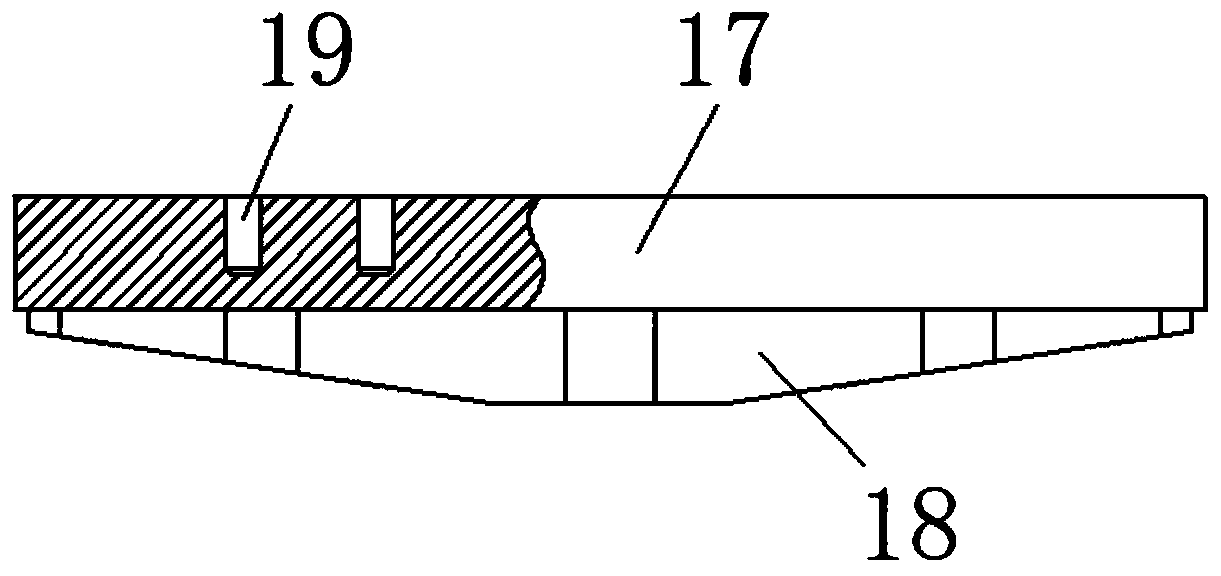

[0029] When the present invention is in use, the track 1 is laid on the ground of the station, the base 2 is installed on the track 1, and then the six-axis robot is placed on the surface of the mounting table 17, and the six-axis robot is fixed on the base 2 by using the fixing seat bolts. The surface of the six-axis robot and the base 2 are respectively connected to the hydraulic station to complete the installation of the six-axis robot.

Embodiment 2

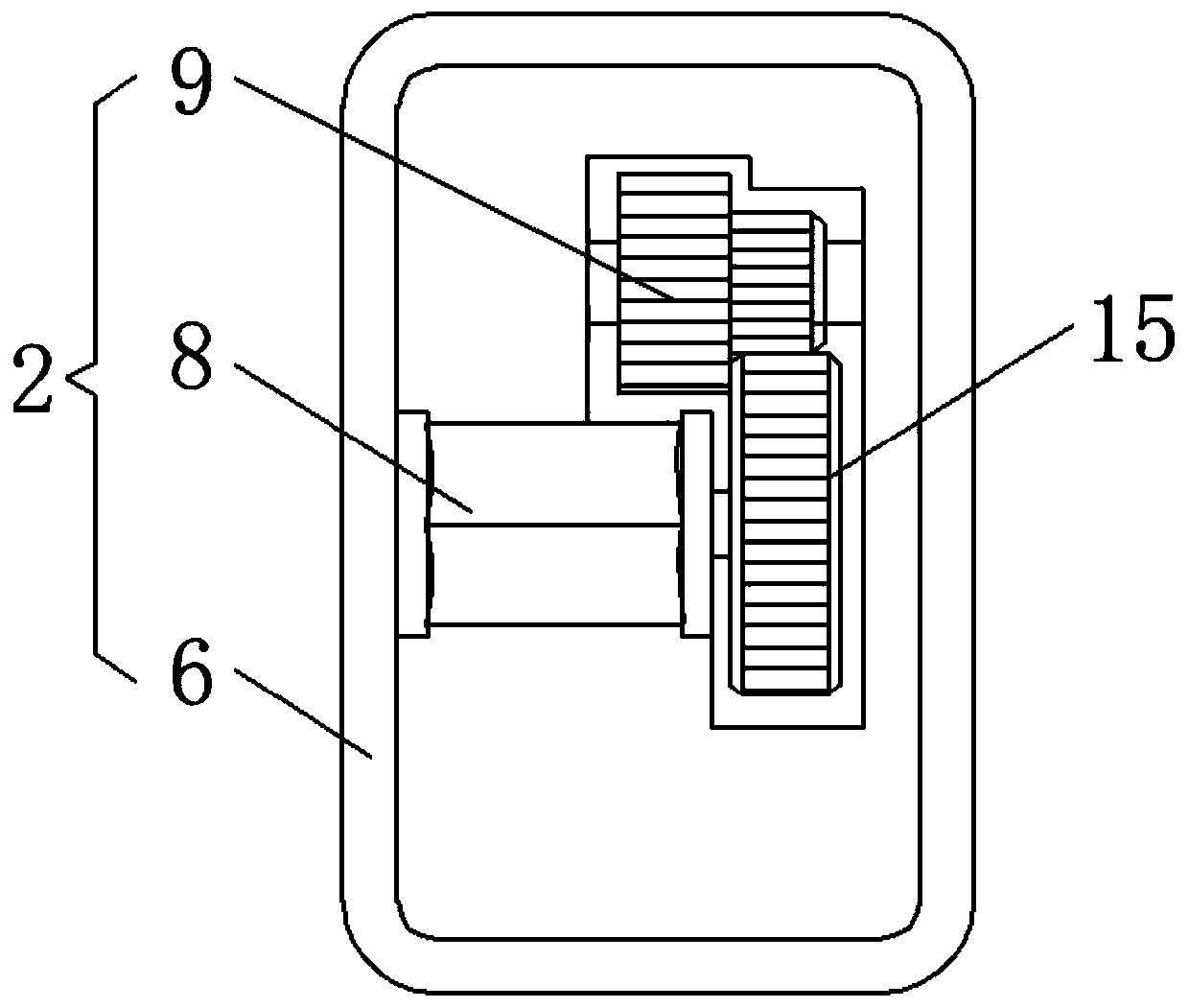

[0031] The present invention has two working states when working, one is a fixed working state, the staff utilizes the hydraulic motor 8 in the base 2 to drive the base 2 to the working position, and then pulls down the turning handle 21 to make the camshaft 14 Squeeze and connect the horizontal plate 12, insert the locking column 11 into the locking hole 20 on the surface of the track 1, and the six-axis robot works in a fixed position; the other is the active working state, when the product needs to be transferred to a long-distance station , by controlling the hydraulic motor 8 to drive the base 2 to continuously reciprocate on the track 1 to transport the product and improve the working flexibility of the six-axis robot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com