Automatic corrugated pipe forming device and method

An automatic forming and bellows technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor diaphragm stability and complex mechanism, and achieve the effect of simple mechanism, reduced driving mechanism, and stable fixed structure of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

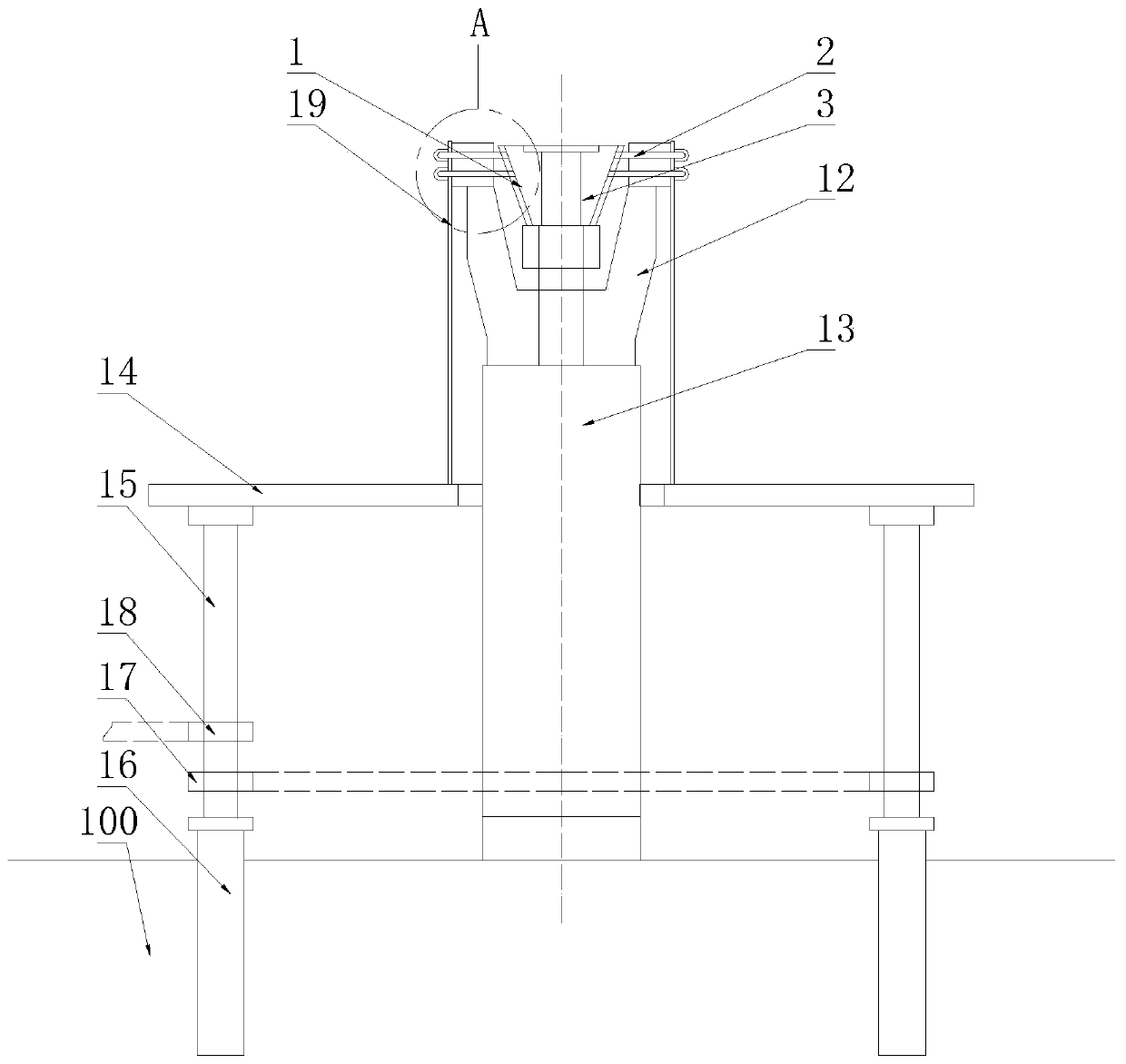

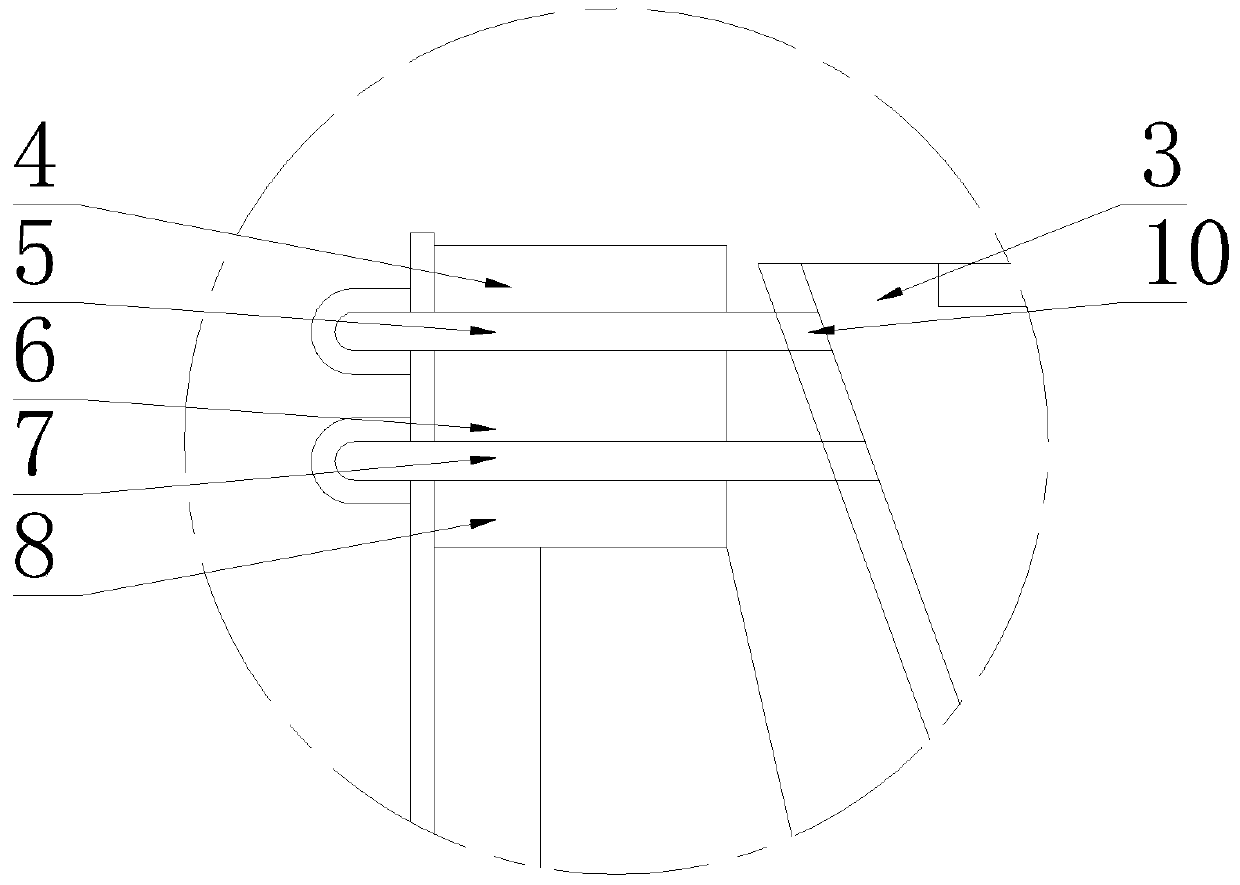

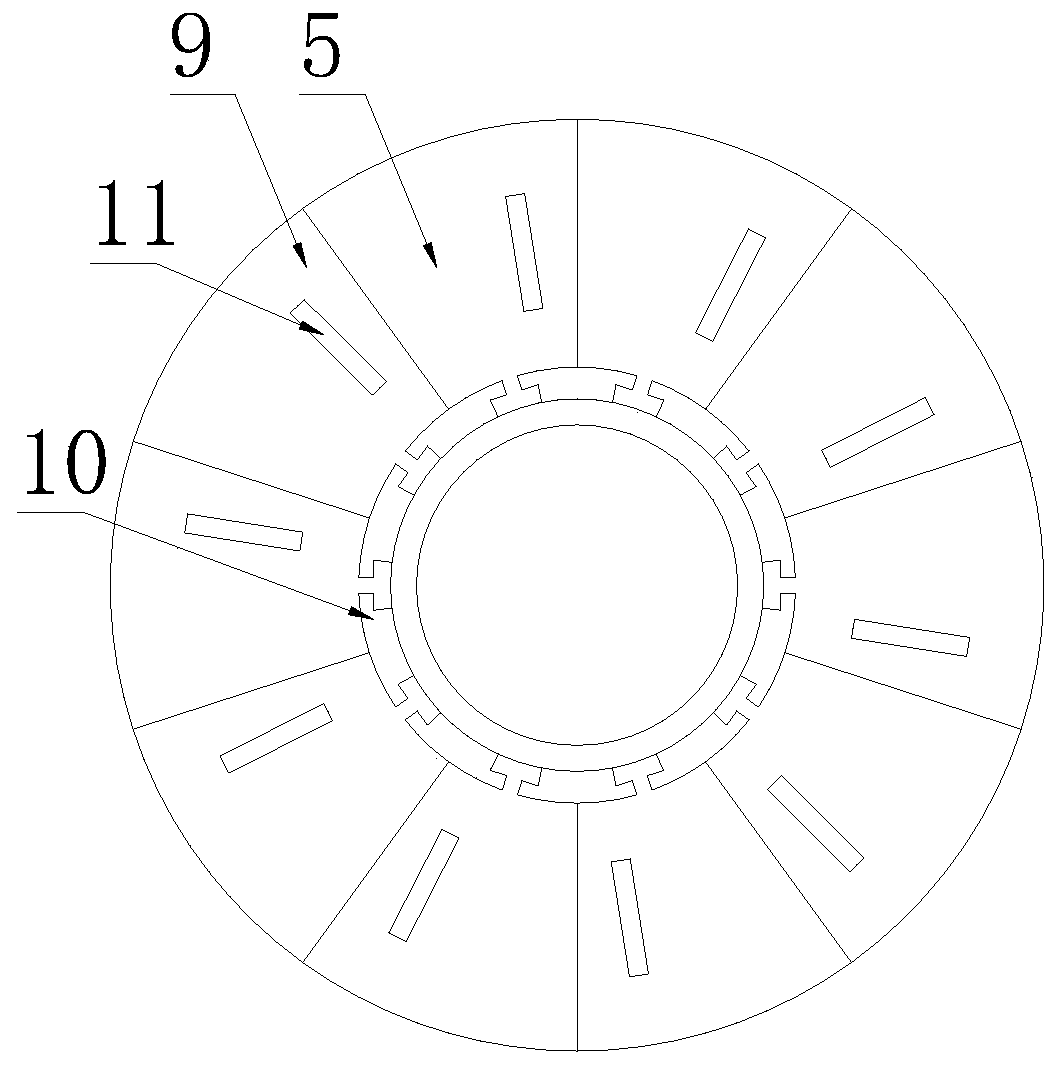

[0029] Such as Figure 1-4 As shown, a bellows automatic forming device includes a bulging device 1 for forming corrugations, and the bulging device 1 includes a die forming mechanism 2 and a conical loading head 3 located at the center of the die forming mechanism 2 The mold forming mechanism 2 includes a pressing plate 4, an upper bulging formwork 5, a splint 6, a lower bulging formwork 7 and a backing plate 8 stacked from top to bottom, and the upper bulging formwork 5 and the lower bulging formwork 7 are composed of The module unit 9 of a plurality of fan rings distributed in an annular array is composed, the inner end of the module unit 9 is provided with a slide block 10, and the outer wall of the conical loading head 3 is provided with a chute arranged in the axial direction, and the slide block 10 embedded in the chute;

[0030] Above-mentioned, the mold unit 9 quantity of last bulging formwork 5 and following bulging formwork 7 is identical, is N, and the angle of ea...

Embodiment 2

[0049] The difference from the first embodiment is that the loading cylinder 13 adopts an adjustable stroke cylinder. The lifting height of the conical loading head 3 can be adjusted by adjusting the stroke of the loading cylinder 13, thereby adjusting the bulging diameters of the upper bulging template 5 and the lower bulging template 7, so as to be suitable for the corrugation forming of tube blanks 19 of various diameters processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com