Functional linseed oil powder composition and preparation method thereof

The technology of linseed oil and composition is applied in the field of functional linseed oil powder composition and preparation thereof, which can solve the problems of easy oxidation, difficult preservation, and high linolenic acid content in linseed oil, so as to prevent constipation and strengthen bones. , good oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

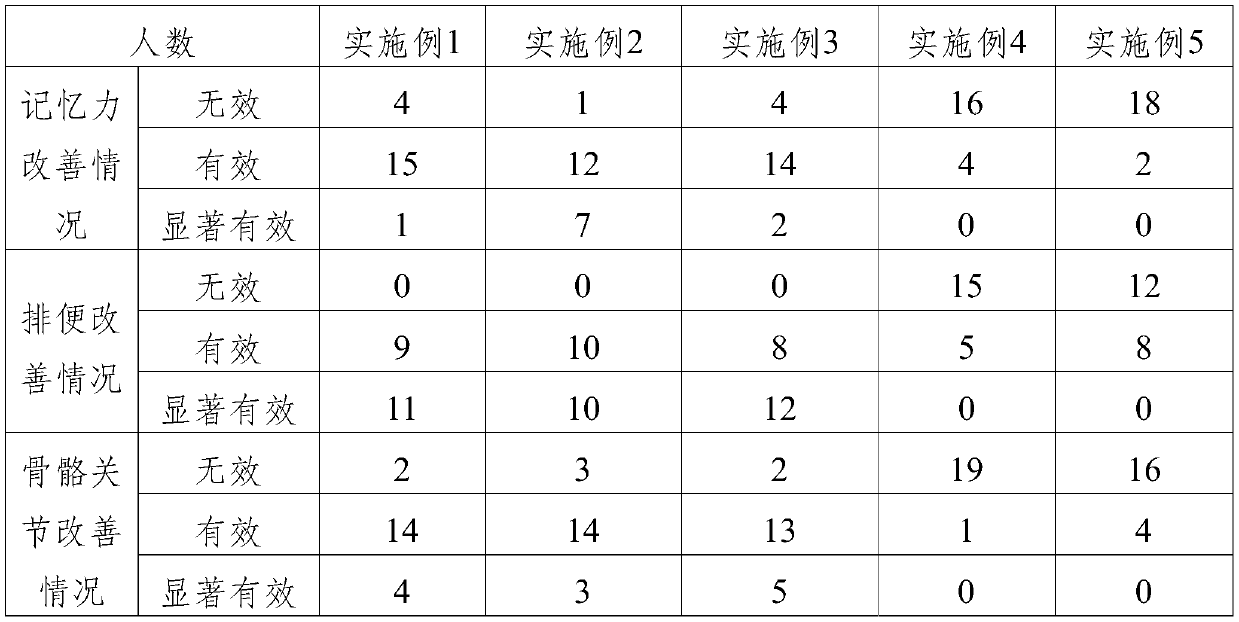

Embodiment 1

[0022] (1) Preparation of linseed oil powder grease

[0023] The analysis conditions of the Rancimat Food Oxidation Analyzer were set at a temperature of 90°C and a gas flow rate of 20L / h. Under these conditions, the linseed oil was screened. Select linseed oil (linolenic acid content is 67.80%, Rancimat oxidation induction time is 9.29h) 300g, phosphatidylserine 8g, monoglyceride 16g, sodium stearoyl lactylate 8g, sodium caseinate 15g, dipotassium hydrogen phosphate 15g, Silica 3g, glucose syrup 635g, prepare linseed oil powder grease. Among all raw materials, the mass ratio of linseed oil is 30%, and the mass ratio of phosphatidylserine is 0.8%.

[0024] The preparation steps are as follows:

[0025] 1) Preparation of oil phase: Stir and mix linseed oil, monoglyceride and sodium stearoyl lactylate.

[0026] 2) Preparation of the water phase: 2L of water (90° C.), phosphatidylserine, sodium caseinate, glucose syrup, dipotassium hydrogen phosphate, and silicon dioxide were ...

Embodiment 2

[0033] (1) Preparation of linseed oil powder grease

[0034] The analysis conditions of the Rancimat Food Oxidation Analyzer were set at a temperature of 90°C and a gas flow rate of 20L / h. Under these conditions, the linseed oil was screened. Choose linseed oil (linolenic acid content is 57.89%, Rancimat oxidation induction time is 8.66h) 300g, phosphatidylserine 13g, monoglyceride 8g, sodium stearoyl lactylate 16g, whey protein concentrate 60g, dipotassium hydrogen phosphate 12g, 2g of silicon dioxide, 40g of modified starch, and 549g of glucose syrup were used as raw materials to prepare linseed oil powder. Among all raw materials, the proportion of linseed oil is 30%, and the proportion of phosphatidylserine is 1.3%.

[0035] The preparation steps are as follows:

[0036] 1) Preparation of oil phase: Stir and mix linseed oil, monoglyceride and sodium stearyl lactylate.

[0037] 2) Preparation of the water phase: 2L of water (85° C.), phosphatidylserine, whey protein conc...

Embodiment 3

[0044] (1) Preparation of linseed oil powder grease

[0045]The analysis conditions of the Rancimat Food Oxidation Analyzer were set at a temperature of 90°C and a gas flow rate of 20L / h. Under these conditions, the linseed oil was screened. Select linseed oil (linolenic acid content is 52.84%, Rancimat oxidation induction time is 12.83h) 400g, phosphatidylserine 11g, monoglyceride 10g, sodium stearoyl lactylate 16g, casein 50g, dipotassium hydrogen phosphate 12g, dioxide 3 g of silicon, 100 g of modified starch, and 398 g of glucose syrup were used as raw materials to prepare linseed oil powder. Among all raw materials, the proportion of linseed oil is 40%, and the proportion of phosphatidylserine is 1.1%.

[0046] The preparation steps are as follows:

[0047] 1) Preparation of oil phase: Stir and mix linseed oil, monoglyceride and sodium stearyl lactylate.

[0048] 2) Preparation of the water phase: 2L of water (70° C.), phosphatidylserine, casein, modified starch, gluco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com