Quality control chart pattern recognition method based on improved genetic algorithm optimization

An improved genetic algorithm and pattern recognition technology, applied in the field of quality control chart pattern recognition based on improved genetic algorithm optimization, can solve the problems of low time-consuming efficiency, slow training speed of BP neural network, unsatisfactory recognition effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

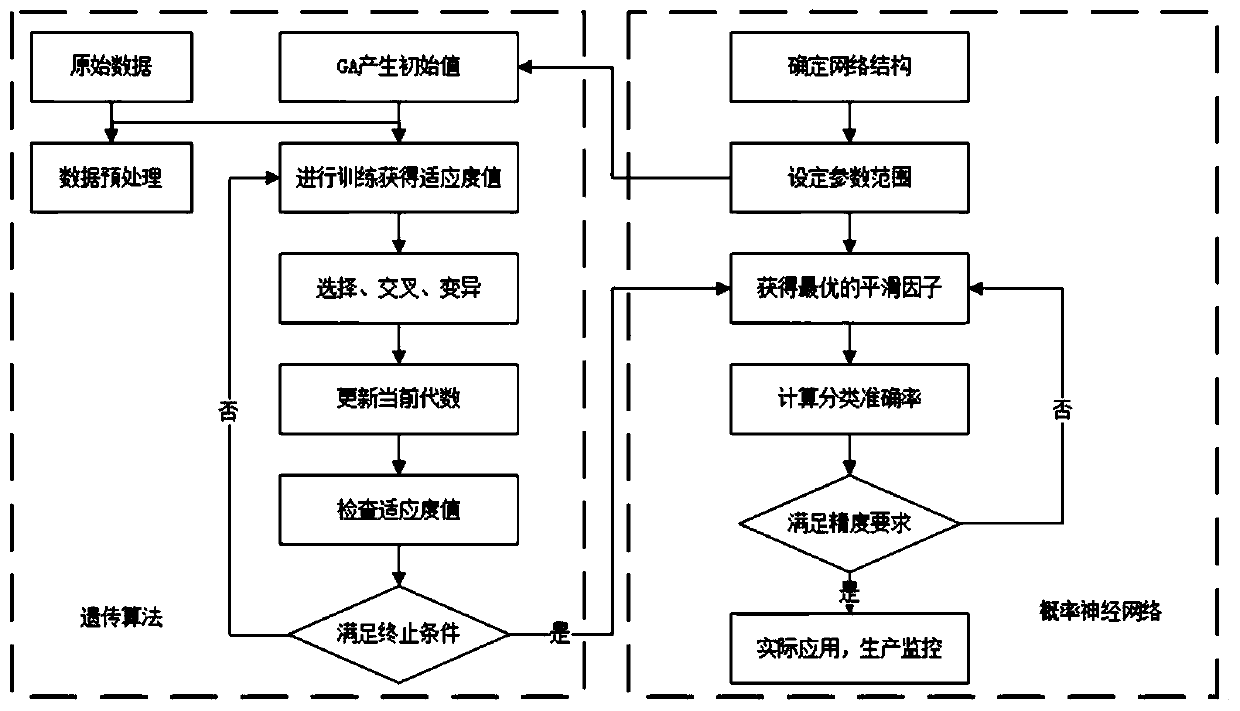

[0072] The present invention will be described in further detail below in conjunction with the accompanying drawings.

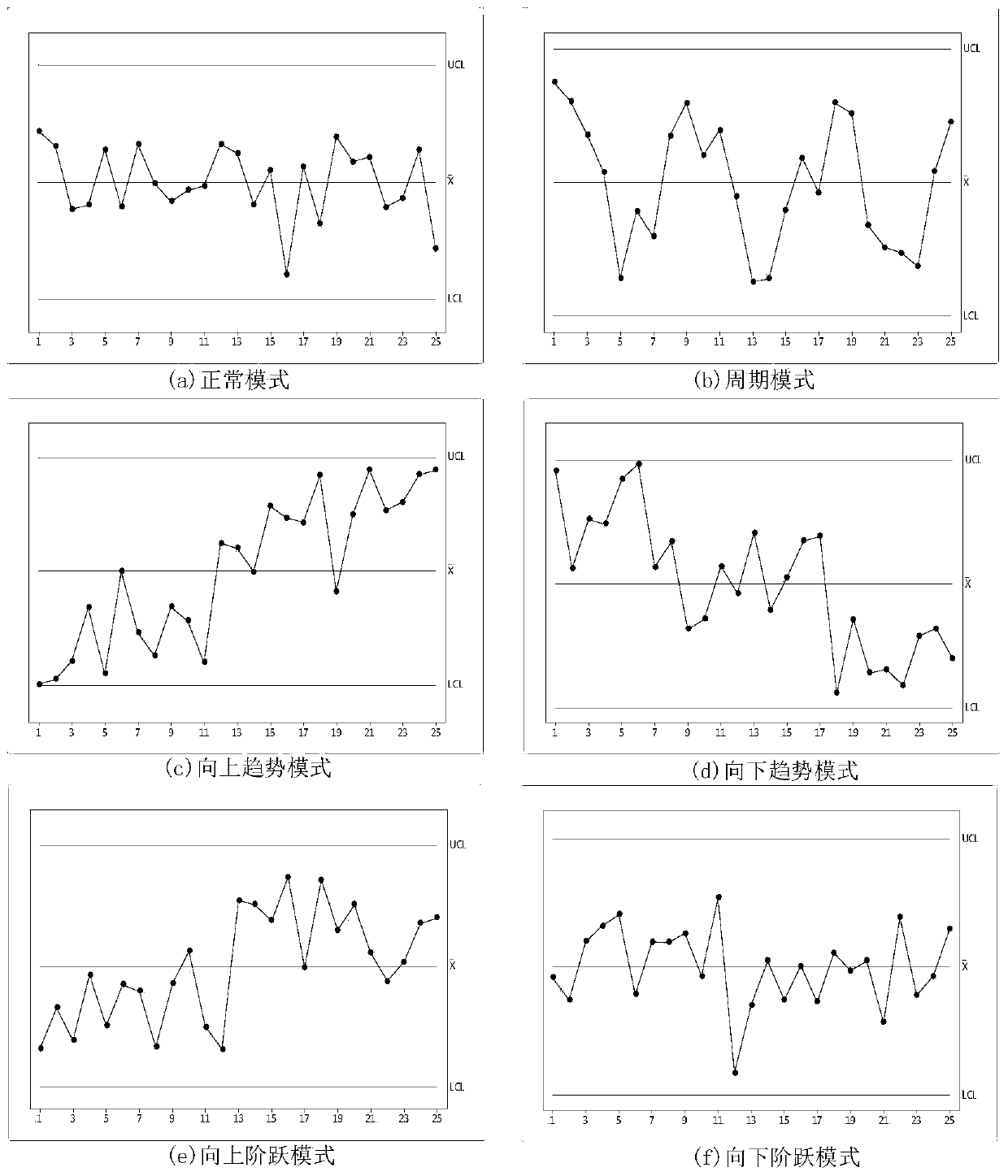

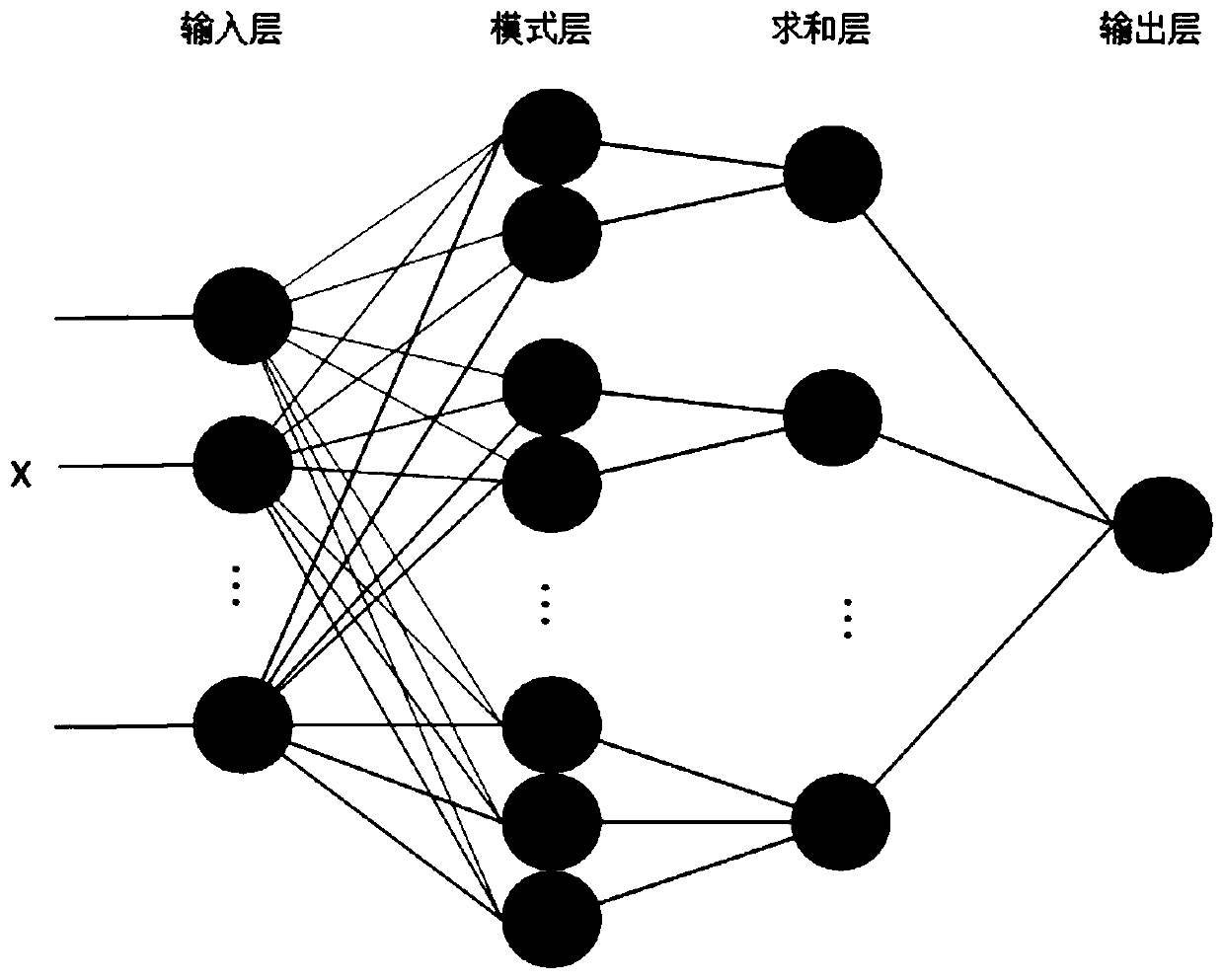

[0073] see Figure 1 to Figure 3 , the SPC control chart in the design of the present invention is the main tool for quality control in the production process. The control chart was first proposed by Dr. Zhu Lan, an American quality expert, to judge whether the production process is in a stable state with a statistical method. Timely alarm prompts can be provided. Therefore, the identification of control chart patterns is the premise of process quality control.

[0074] According to GB / T4091-2000 proposed eight kinds of control chart anomaly judging criteria based on statistical principles, it can monitor and give early warning of out-of-control phenomena in the production process. However, due to the random fluctuations in the production process, that is, noise, these criteria cannot cover all out-of-control situations, and the combination explosion of rul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com