Frame type decoration structure and mounting method thereof

A frame-type and frame-based technology, which is applied in the direction of building components, building structures, covering/lining, etc., can solve the problems that workers are difficult to adjust the support parts of the board, the flatness is not ideal, and the installation efficiency is low, so as to achieve the overall stability of the decoration structure , Improve the efficiency of positioning and installation, and improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

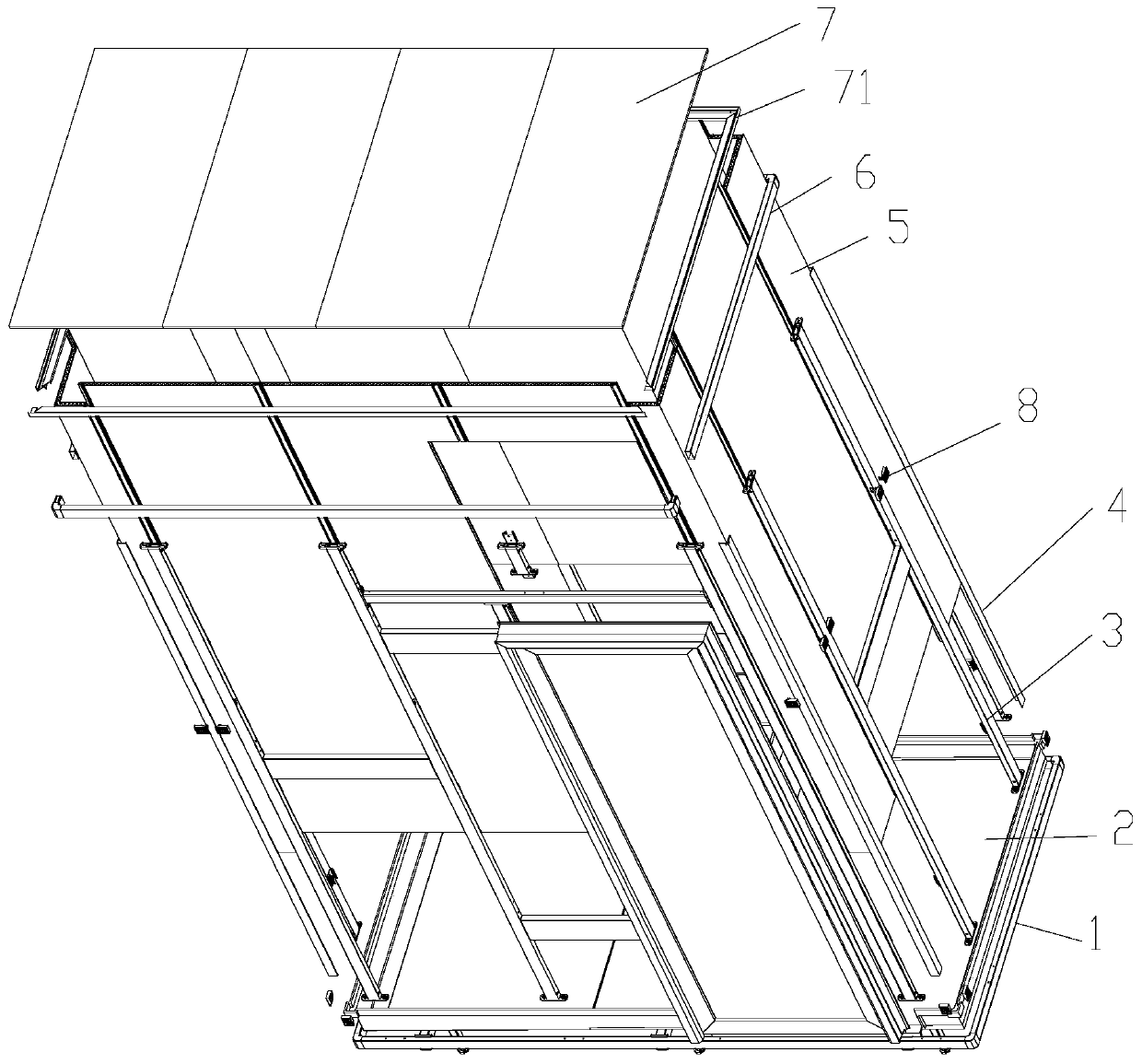

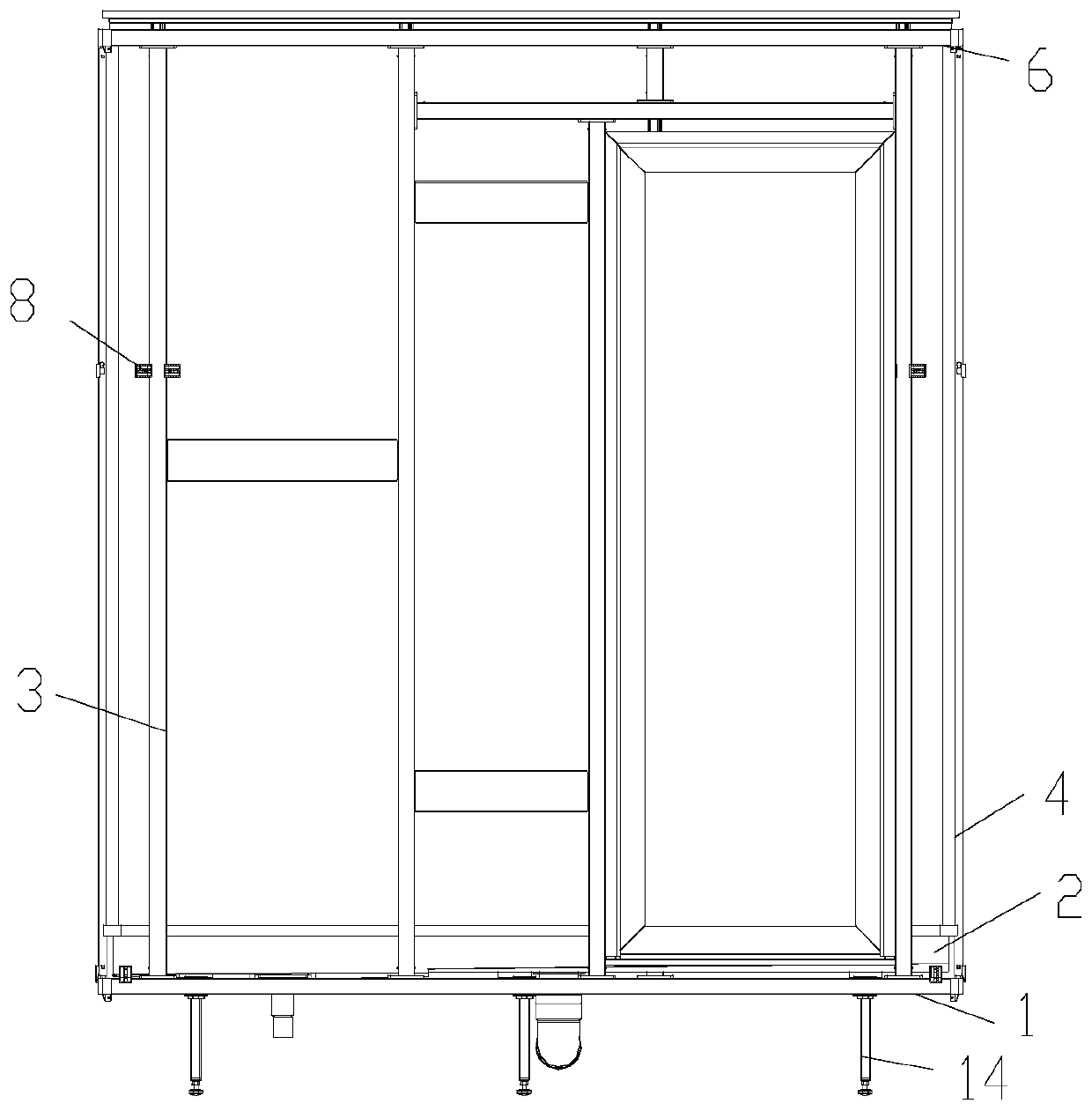

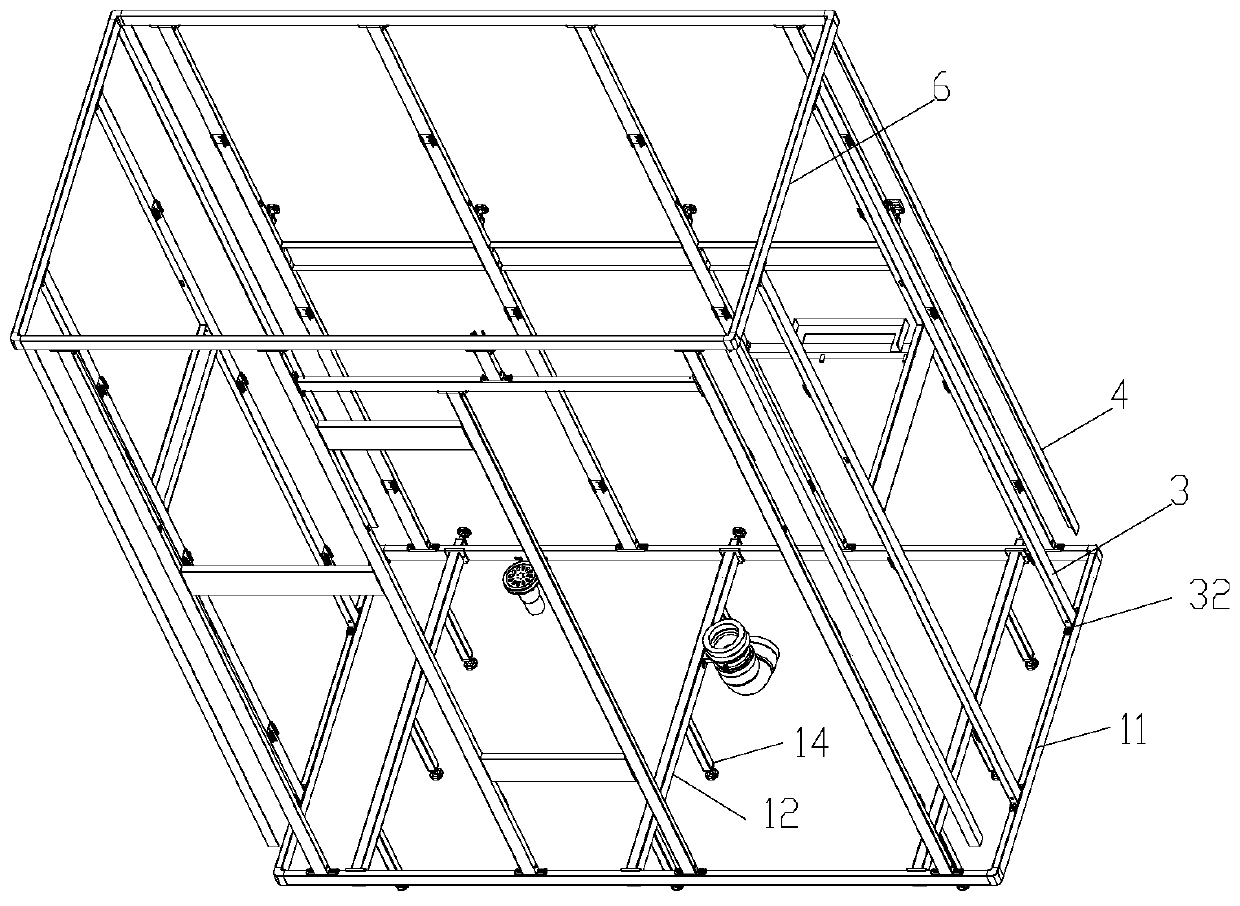

[0086] This embodiment is a frame type decoration structure, which is set in the indoor space, and its structure is as follows: Figure 1 to Figure 20 Shown; Including ground structure, wall structure, ceiling 7 and upper frame 6.

[0087] The ground structure includes a floor support bracket 1 , adjustment feet 13 , lifting feet 14 and floor panels 2 . The floor support frame 1 is set on the solid ground through the lifting feet 14; the floor support frame 1 is provided with adjustment feet 13; the horizontal direction positioning of the floor support frame 1 is realized through the support of the adjustment feet 13 and the solid wall. In practical application, it is also possible that the floor support bracket 1 is provided with adjustment feet 13 above both sides. The floor panel 2 is supported on the floor support frame 1 .

[0088] The wall structure includes several middle frames 3, corner frames 4, upper frames 6 and wall panels 5; the corner frames 4 are arranged on ...

Embodiment 2

[0121] The difference between the frame decoration structure of this embodiment and Embodiment 1 is that: in this embodiment, if Figure 21 to Figure 23 As shown, the lower part of the floor panel 2 is fixedly provided with a reinforcement frame 29; the reinforcement frame is arranged on the floor support frame 1, and the reinforcement frame 29 is provided with a frame connection part 291, and the frame connection part 291 and the floor support frame 1 adopt screws and bolts and other connectors. The rest of the structure of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0123] The difference between the frame decoration structure of this embodiment and the first embodiment is that: in this embodiment, the decoration structure is not provided with a floor drain assembly, and the floor panel is not provided with a floor drain. The rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com