Compound containing cyanobenzene or thiocyanobenzene, and applications in organic electroluminescent devices

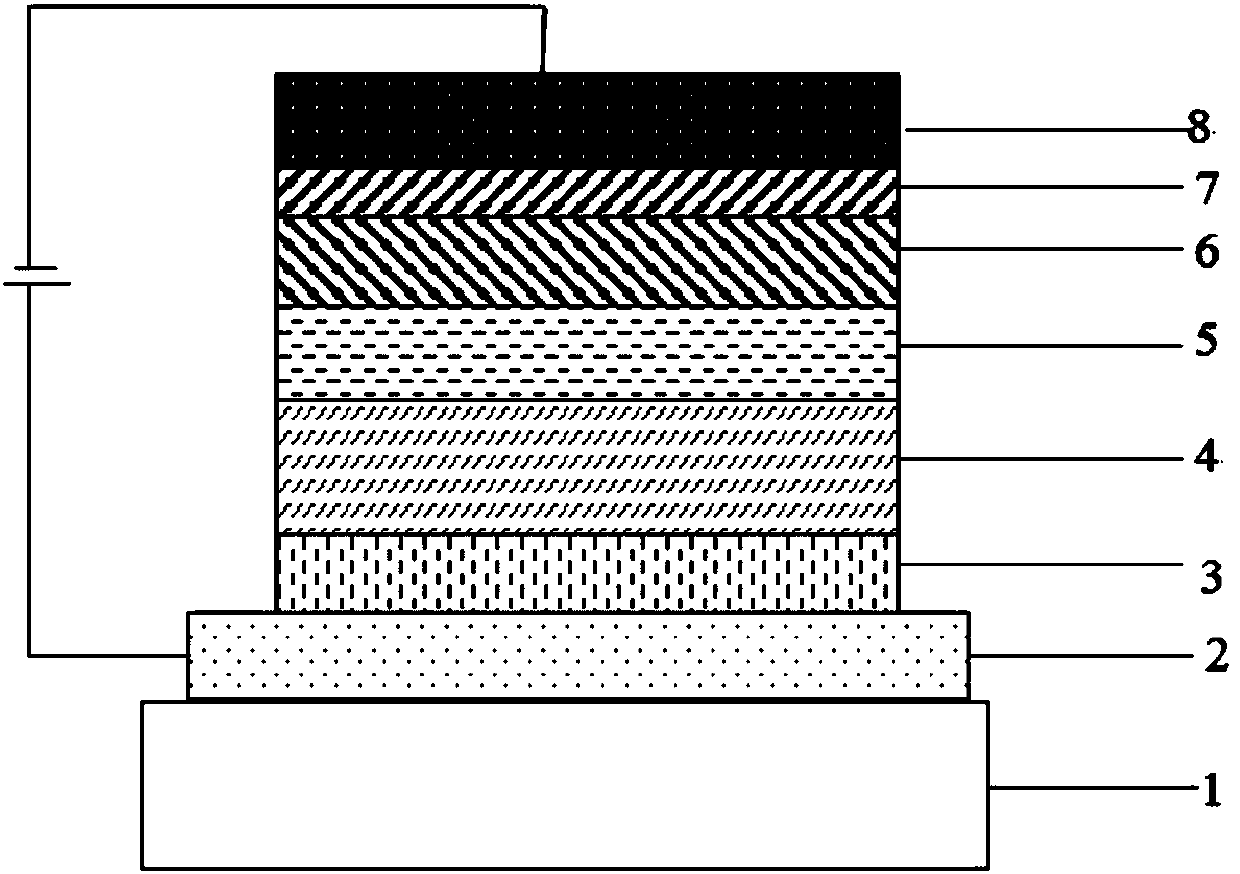

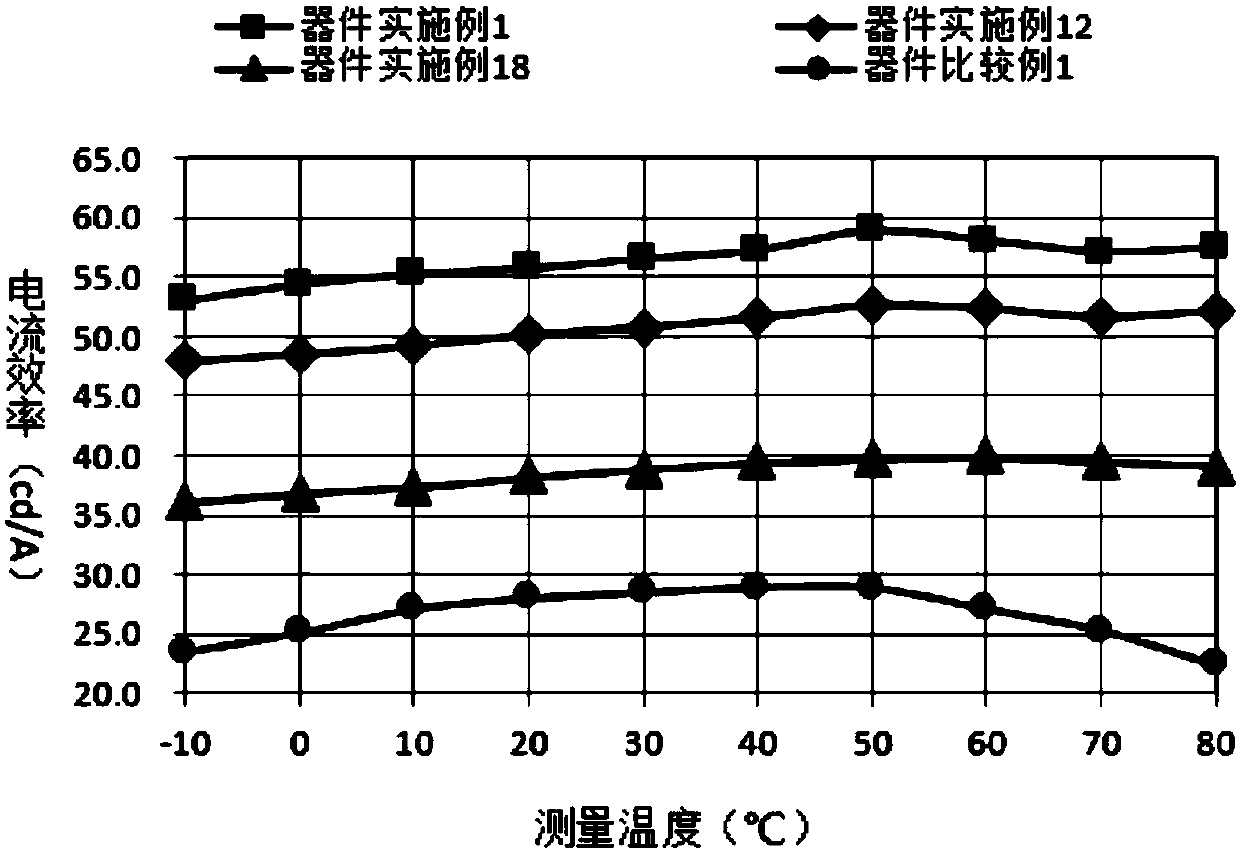

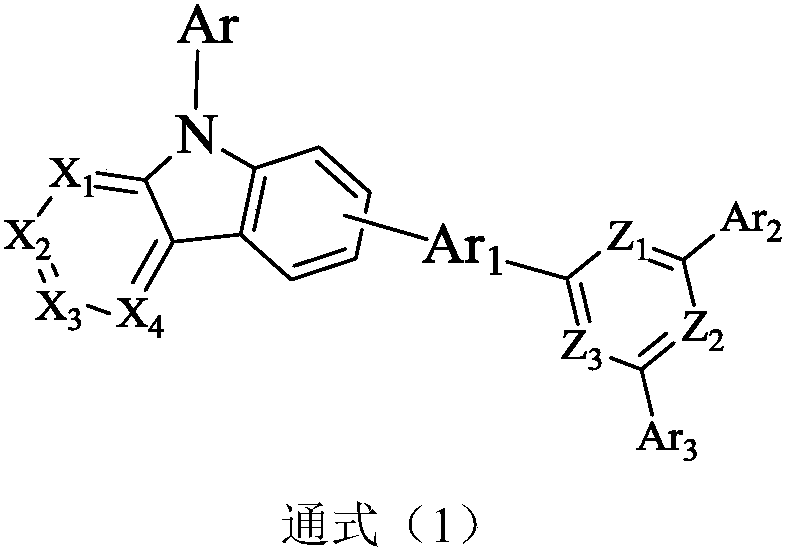

A technology of thiocyanobenzene and compounds, which can be used in electric solid devices, electrical components, light-emitting materials, etc., can solve problems such as differences, and achieve the effects of avoiding aggregation, good industrialization prospects, and good film-forming properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: the synthesis of intermediate M:

[0044]

[0045] (1) Dissolve raw material B and raw material C in a mixed solution of toluene and ethanol, add Pd(PPh 3 ) 4 and K 2 CO 3 , react at 95-110°C for 10-24 hours under an inert atmosphere, monitor the reaction process with TLC during the reaction process, cool and filter the raw materials after the reaction is complete, spin the filtrate to remove the solvent, and pass the crude product through a silica gel column to obtain Intermediate S; the consumption of described toluene and ethanol is to use 30~50mL toluene and 5~10mL ethanol per gram of raw material C, the molar ratio of raw material B and raw material C is (1~1.5):1, Pd(PPh 3 ) 4 The molar ratio with raw material C is (0.006~0.02):1, K 2 CO 3 The molar ratio with raw material C is (1.5~2):1.

[0046] (2) Under the protection of nitrogen, weigh 0.01mol of intermediate S and dissolve it in 150ml of tetrahydrofuran, cool to -78°C, then add 1.6mol...

Embodiment 2

[0056] Embodiment 2: the synthesis of compound 1:

[0057]

[0058] In a 250mL three-necked flask, dissolve 0.01mol of raw material A-1 and 0.012mol of raw material B-1 in 150mL of toluene and ethanol (V 甲苯 :V 乙醇 =5:1) In the mixed solution, add 0.0002mol Pd(PPh 3 ) 4 and 0.02mol K 2 CO 3 , reacted at 110°C for 24 hours under an inert atmosphere, and continuously monitored the reaction process with TLC during the reaction process. After the raw materials were completely reacted, cooled and filtered, the filtrate was rotary evaporated to remove the solvent, and the crude product was passed through a silica gel column to obtain the target product; element Analytical structure (molecular formula C 36 h 23 N 3 ): theoretical value C, 86.90; H, 4.66; N, 8.44; test value: C, 86.95; H, 4.72; N, 8.47; for 497.23.

Embodiment 3

[0059] Embodiment 3: the synthesis of compound 3:

[0060]

[0061] In a 250mL three-neck flask, dissolve 0.01mol of raw material A-1 and 0.012mol of raw material B-4 in 150mL of toluene and ethanol (V 甲苯 :V 乙醇 =5:1) In the mixed solution, add 0.0002mol Pd(PPh 3 ) 4 and 0.02mol K 2 CO 3 , reacted at 110°C for 24 hours under an inert atmosphere, and continuously monitored the reaction process with TLC during the reaction process. After the raw materials were completely reacted, cooled and filtered, the filtrate was rotary evaporated to remove the solvent, and the crude product was passed through a silica gel column to obtain the target product; element Analytical structure (molecular formula C 36 h 23 N 3 S): theoretical value C,81.64; H,4.38; N,7.93; S,6.05; test value: C,81.67; H,4.39; N,7.97; S,6.08; ): The theoretical value is 529.16, and the measured value is 529.18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com