Water-soluble humic acid production method

A technology of water-soluble humic acid and production method, which is applied in the directions of organic fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of difficult absorption and utilization of nutrients, inability to decompose chemical residues, and inability to improve soil, etc. Recycling and recycling, solving the effect of not effectively improving soil and being absorbed and utilized by crops, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

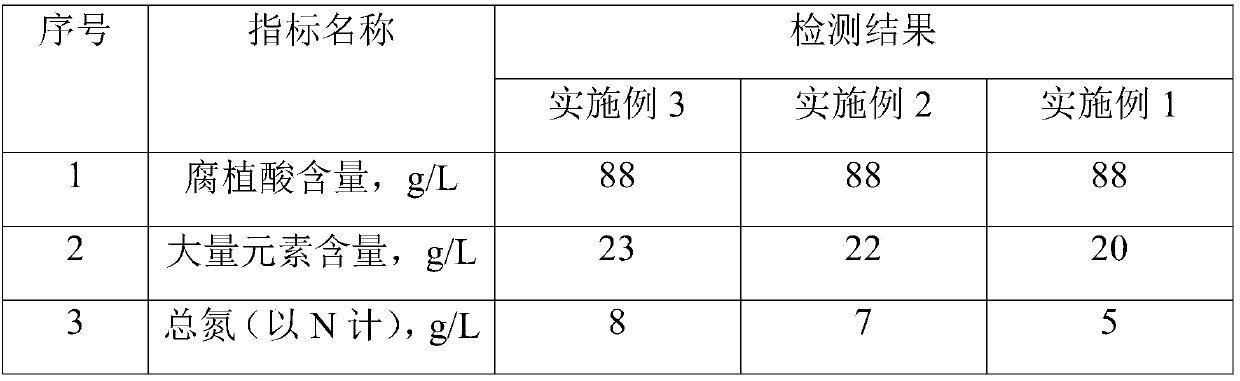

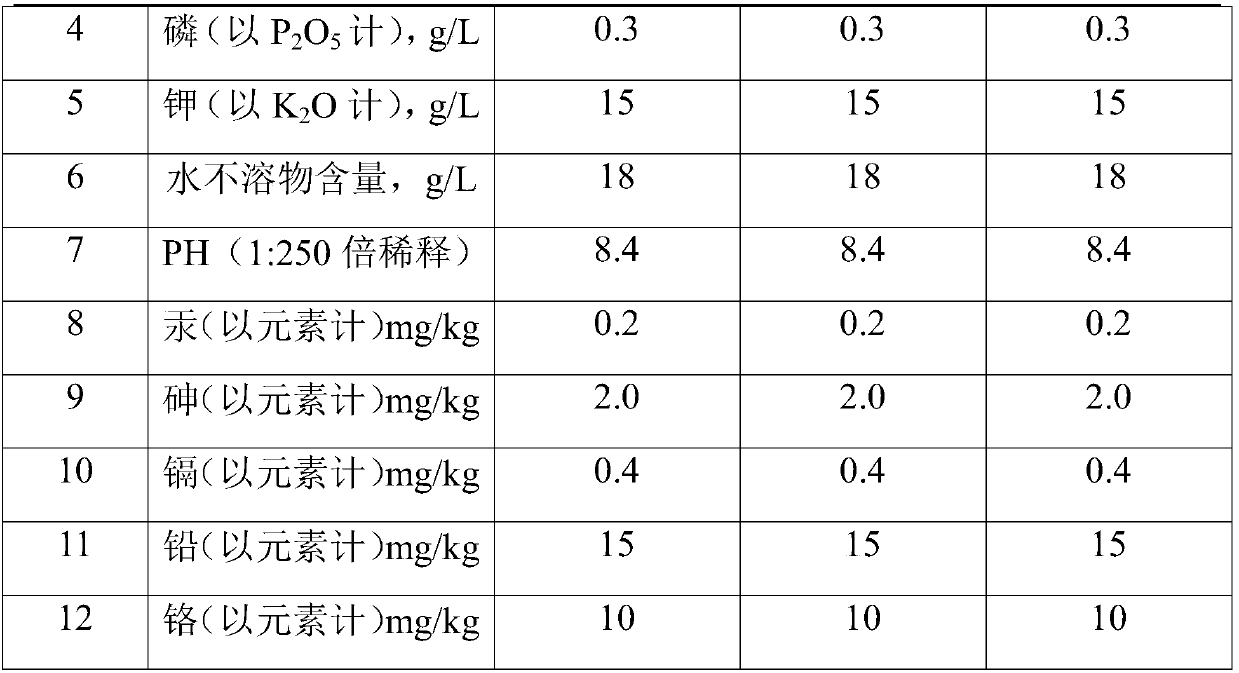

Embodiment 1

[0023] Step1: Add starch wastewater from potatoes and sodium hydroxide or potassium hydroxide (100mL: 1.0-1.3g) into the reaction kettle to make the pH value reach 9, and heat until the mixture boils;

[0024] Step2: Add mineral humic acid into the boiling mixed solution according to the ratio of mineral humic acid: mixed solution = 1g: 3.5mL, heat and stir.

[0025] Step3: Control the temperature of the reactor at 95°C, keep it for 3 hours, then lower the temperature to 80°C, and keep it for another 3 hours.

Embodiment 2

[0027] Step1: Add starch wastewater from potatoes and sodium hydroxide or potassium hydroxide (100mL: 1.0-1.3g) into the reaction kettle to make the pH value reach 9, and heat until the mixture boils;

[0028] Step2: Add mineral humic acid into the boiling mixed solution according to the ratio of mineral humic acid: mixed solution = 1g: 3.5mL, heat and stir.

[0029] Step3: Control the temperature of the reactor to 90°C, keep it for 2 hours, then lower the temperature to 80°C, and keep it for 3 hours.

Embodiment 3

[0031] Step1: Add starch wastewater from potatoes and sodium hydroxide or potassium hydroxide (100mL: 1.0-1.3g) into the reaction kettle to make the pH value reach 9, and heat until the mixture boils;

[0032] Step2: Add mineral humic acid into the boiling mixed solution according to the ratio of mineral humic acid: mixed solution = 1g: 3.5mL, heat and stir.

[0033] Step3: Control the temperature of the reactor to 90°C, keep it for 2 hours, then lower the temperature to 80°C, and keep it for another 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com