Wave suppression type water maintenance platform for seaplane

A seaplane and platform technology, applied to seaplanes, boats used for aircraft, motor vehicles, etc., can solve the problems of lack of water maintenance project design, inability to guarantee the safety and reliability of water maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

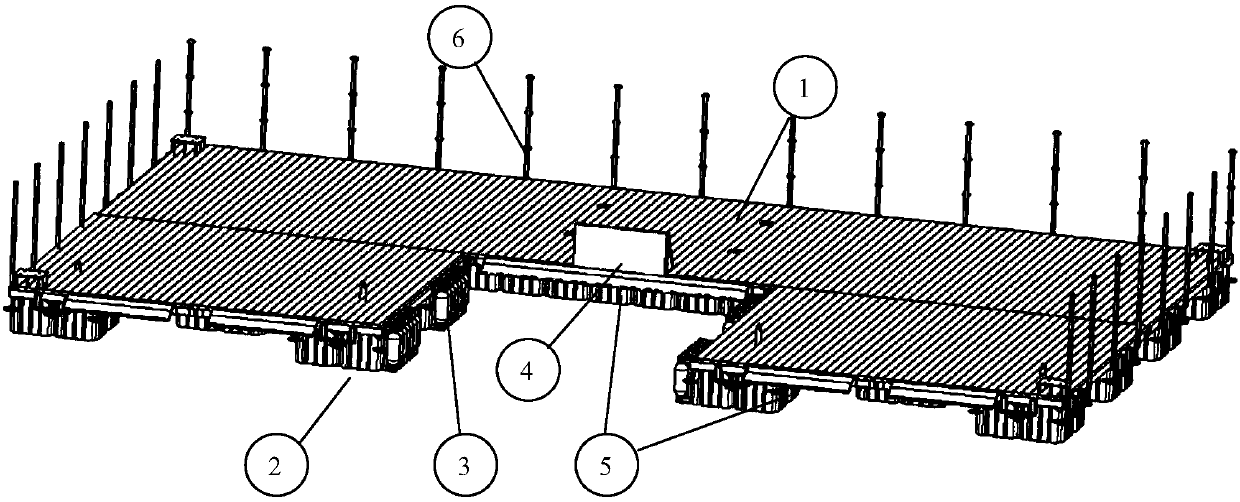

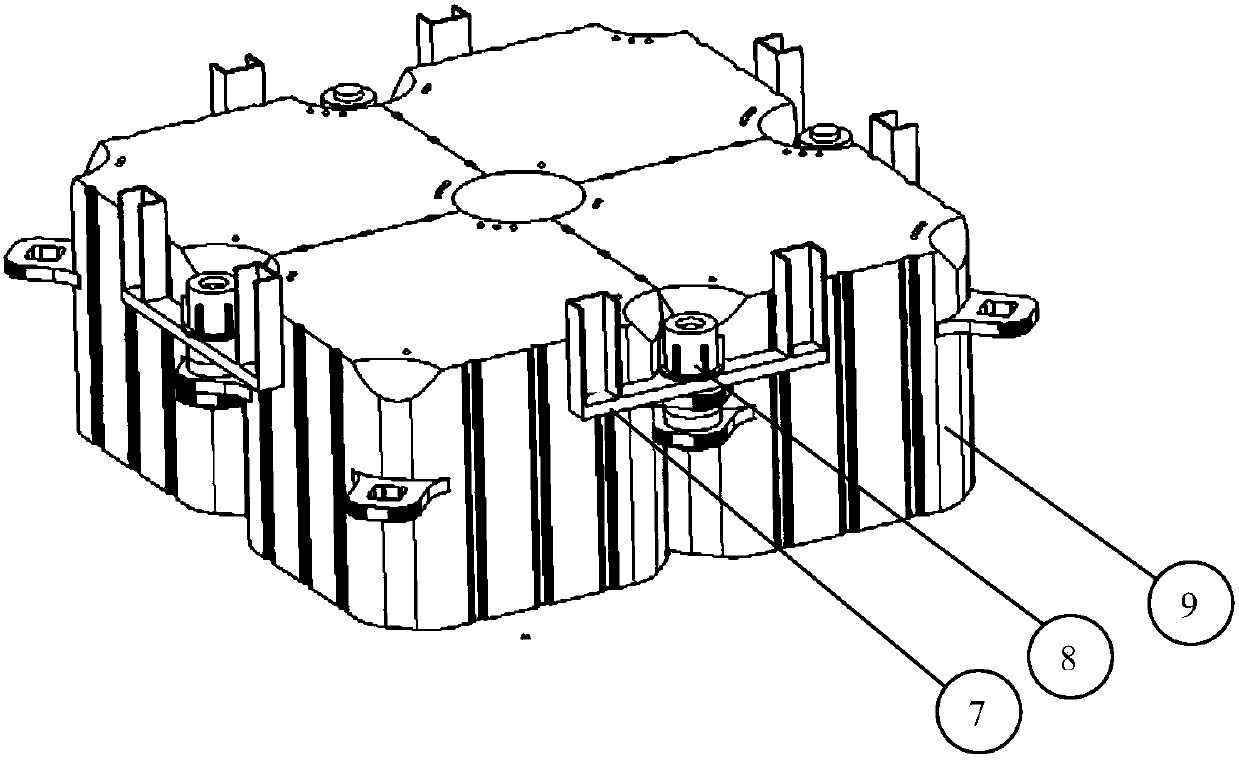

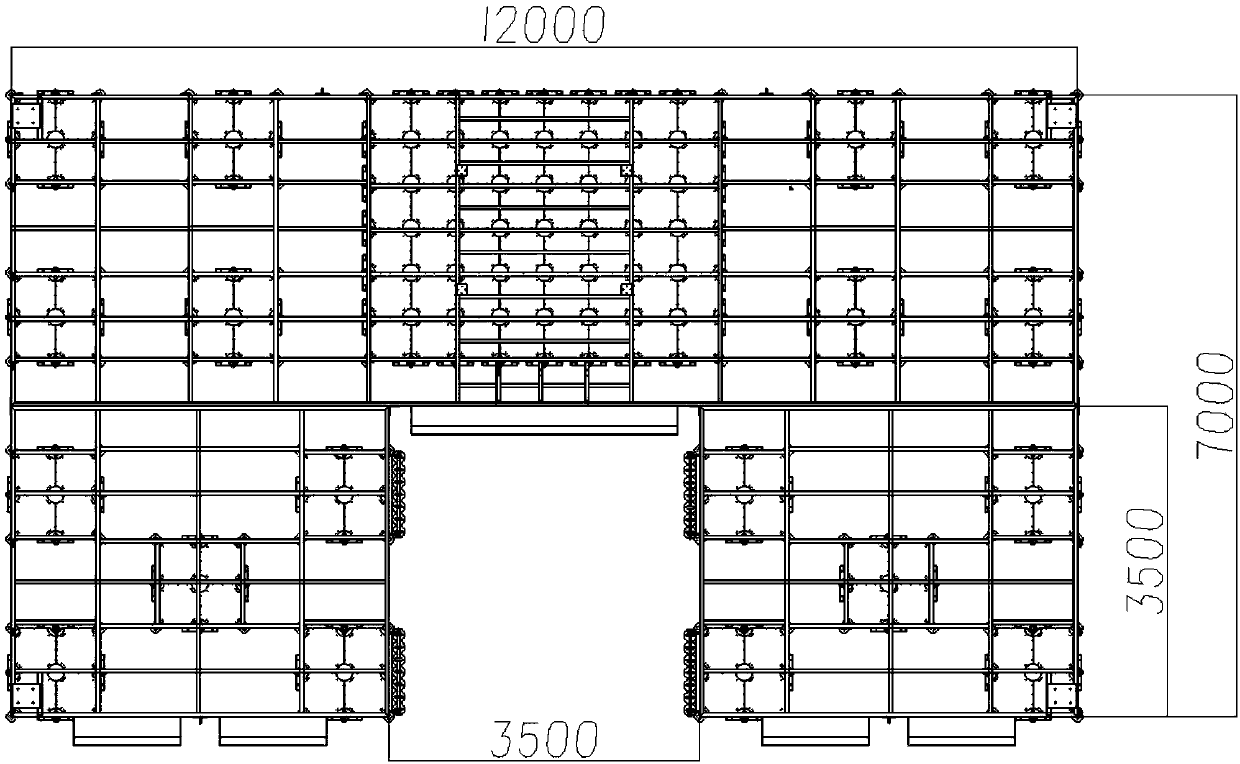

[0026] see figure 1 It is the suitable connection interface layout of the water maintenance platform combined with the nose and wing cutting of the seaplane provided by the present invention. The platform buoys form a group of four components that are evenly distributed on the rigid frame, ensuring that the platform has sufficient buoyancy and reduces the overall cost of the platform. weight. It can make the seaplane and the maintenance platform form a perfect system structure, which is convenient for the maintenance personnel to carry out the inspection and maintenance work of the maintenance on the water. The wave-suppressing water maintenance platform of the seaplane includes a platform rigid frame 1, a buoy assembly 2, a buffer device 3, an anti-collision baffle 4, a wave-suppressing plate 5 and a guar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com