A textile fiber press molding device

A compression molding and textile fiber technology, which is applied in the field of textile fiber compression molding device and fiber cotton manufacturing process, can solve the problems of reducing the utilization rate of fiber cotton material, restricting the shape of fiber cotton, and long processing process, so as to improve the material utilization rate , reduce the amount of waste, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

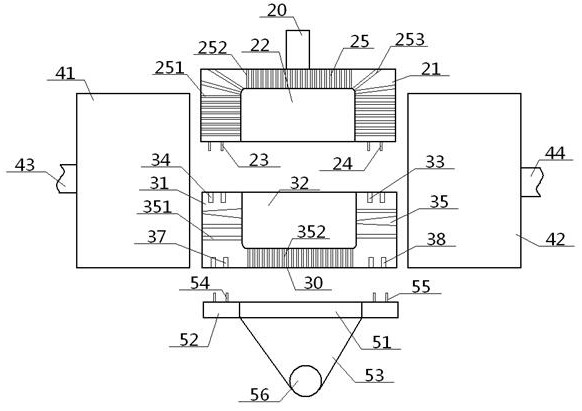

[0055] see figure 1 - Figure 12, a kind of textile fiber pressing molding device, comprises upper mold 2 and lower mold 3 arranged up and down, and hollow outer sleeve 4, and this outer sleeve 4 is set on the outside of upper mold 2, lower mold 3, and outer sleeve 4 The height is greater than the sum of the heights of the upper mold 2 and the lower mold 3, and the width of the inner wall of the outer sleeve 4 is greater than the width of the upper mold 2 and the lower mold 3; Mold cavity 22, lower mold 3 comprises lower mold body 31 and the lower mold cavity 32 that its inside offers, and upper mold cavity 22, lower mold cavity 32 butt up and down to form a molding cavity 1; The top surface of described upper mold body 21 and The lower pressing shaft 20 is connected, and the bottom surface of the upper mold body 21 is provided with a concentric upper inner slide rail 23 and an upper outer slide rail 24 around the position of the upper mold cavity 22. The upper inner slide ra...

Embodiment 2

[0057] Basic content is the same as embodiment 1, the difference is:

[0058] The top surface of the lower mold body 31 is sandwiched between the lower inner chute 33 and the lower outer chute 34. A concave partition groove 36 is provided. The partition groove 36 is an annular structure, and the partition groove 36 includes The partition straight cavity 361 , the partition inner concave cavity 362 , and the partition bottom cavity 363 are connected in sequence from top to bottom, and the widths of the partition straight cavity 361 and the partition bottom cavity 363 are greater than the maximum width of the partition inner concave cavity 362 .

Embodiment 3

[0060] Basic content is the same as embodiment 1, the difference is:

[0061] The air injection device 5 includes an air outlet 51, an outer ring disk 52 and an air containment cover 53. The air containment cover 53 is a conical structure with a wide top and a narrow bottom. The bottom end of the air containment cover 53 is connected with the air intake pipe 56 , the top of the air containment cover 53 is connected to the air outlet 51, the outer ring of the air outlet 51 is provided with an outer ring disk 52, and the top surface of the outer ring disk 52 is provided with concentric inner air around the air outlet 51. The slide rail 54, the external air slide rail 55, the internal air slide rail 54, and the external air slide rail 55 are all ring structures, and the bottom surface of the lower die body 31 is provided with concentric air slide rails around the air intake area 30. Groove 37, air outer chute 38, air inner chute 37, air outer chute 38 are all annular structures, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com