Mine dust removal system and dust removal method thereof

A technology for dust removal systems and mines, applied in separation methods, chemical instruments and methods, controllers with specific characteristics, etc., can solve the problems of small processing air volume, affecting dust removal efficiency, and poor atomization degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

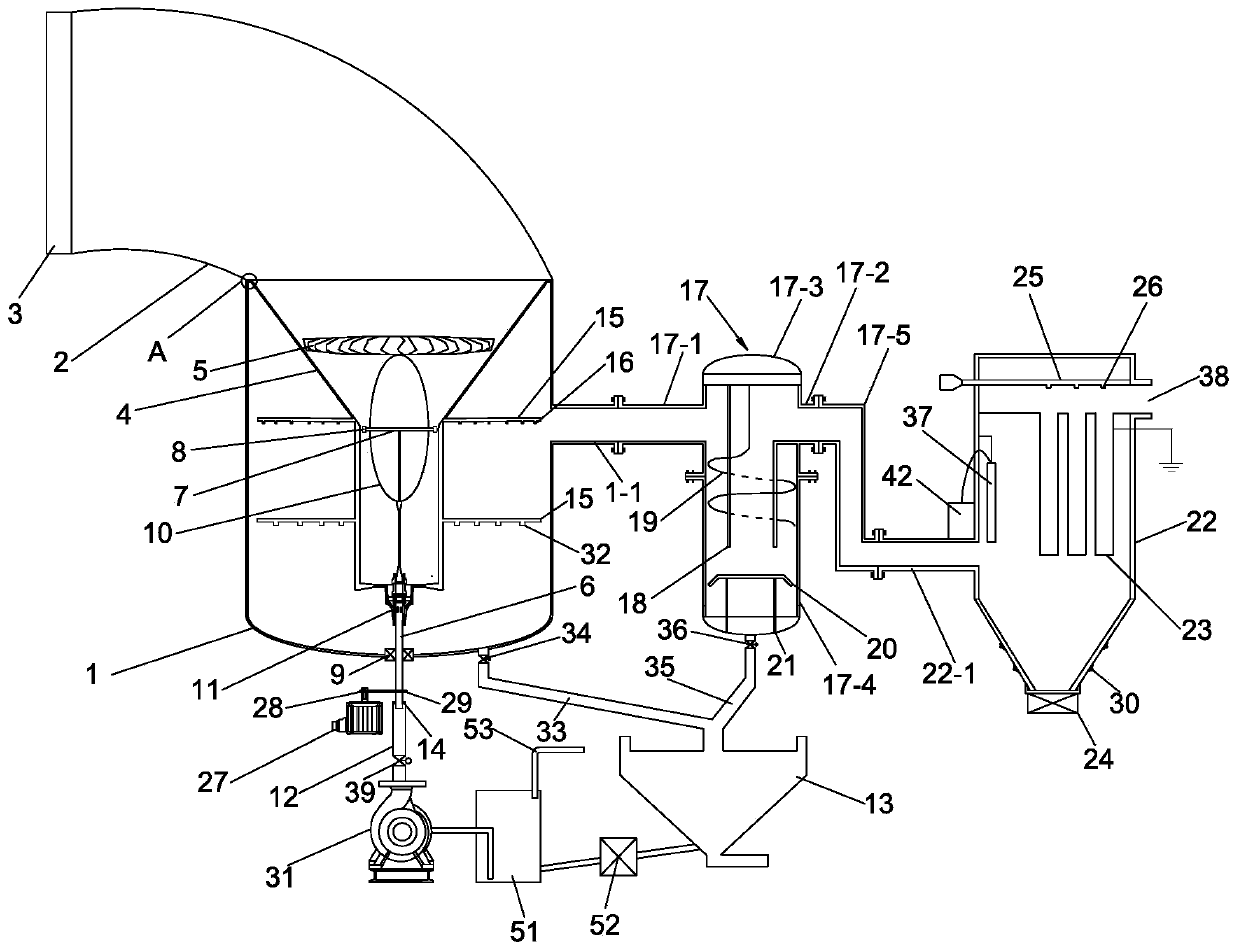

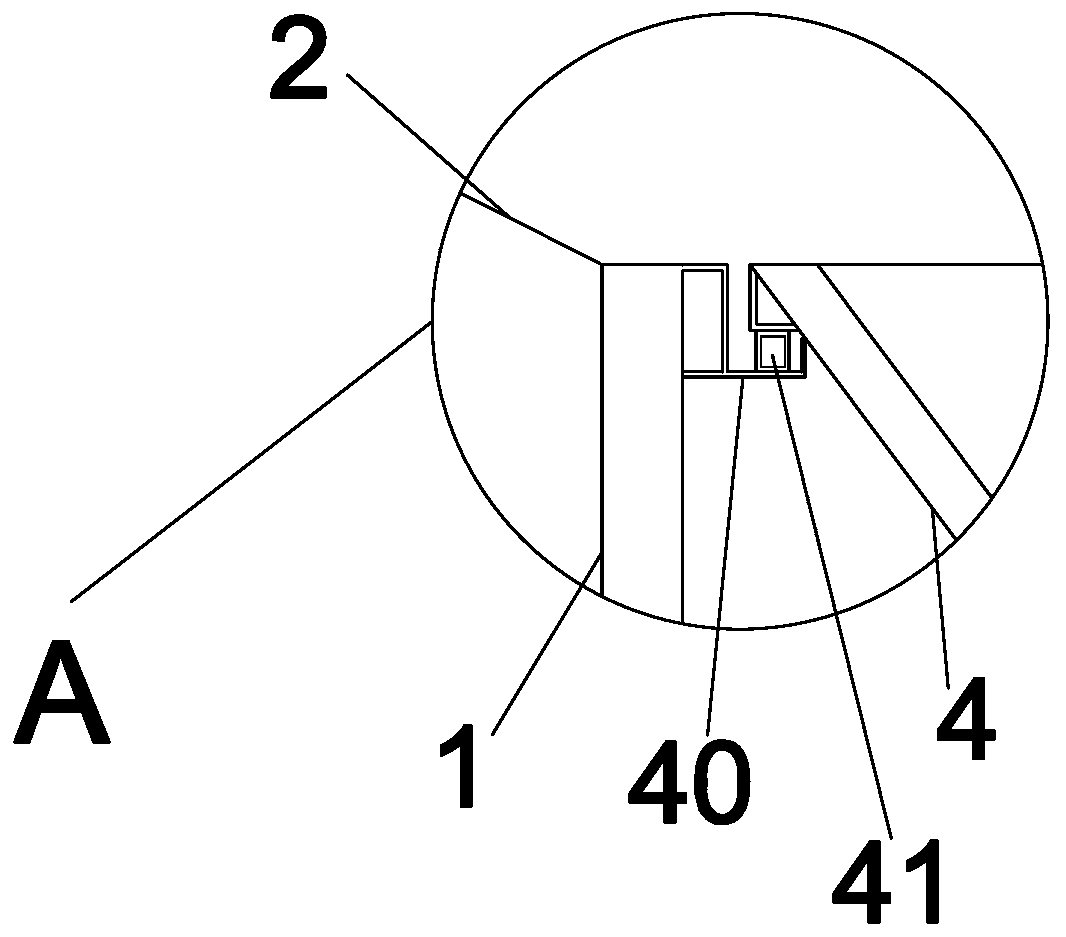

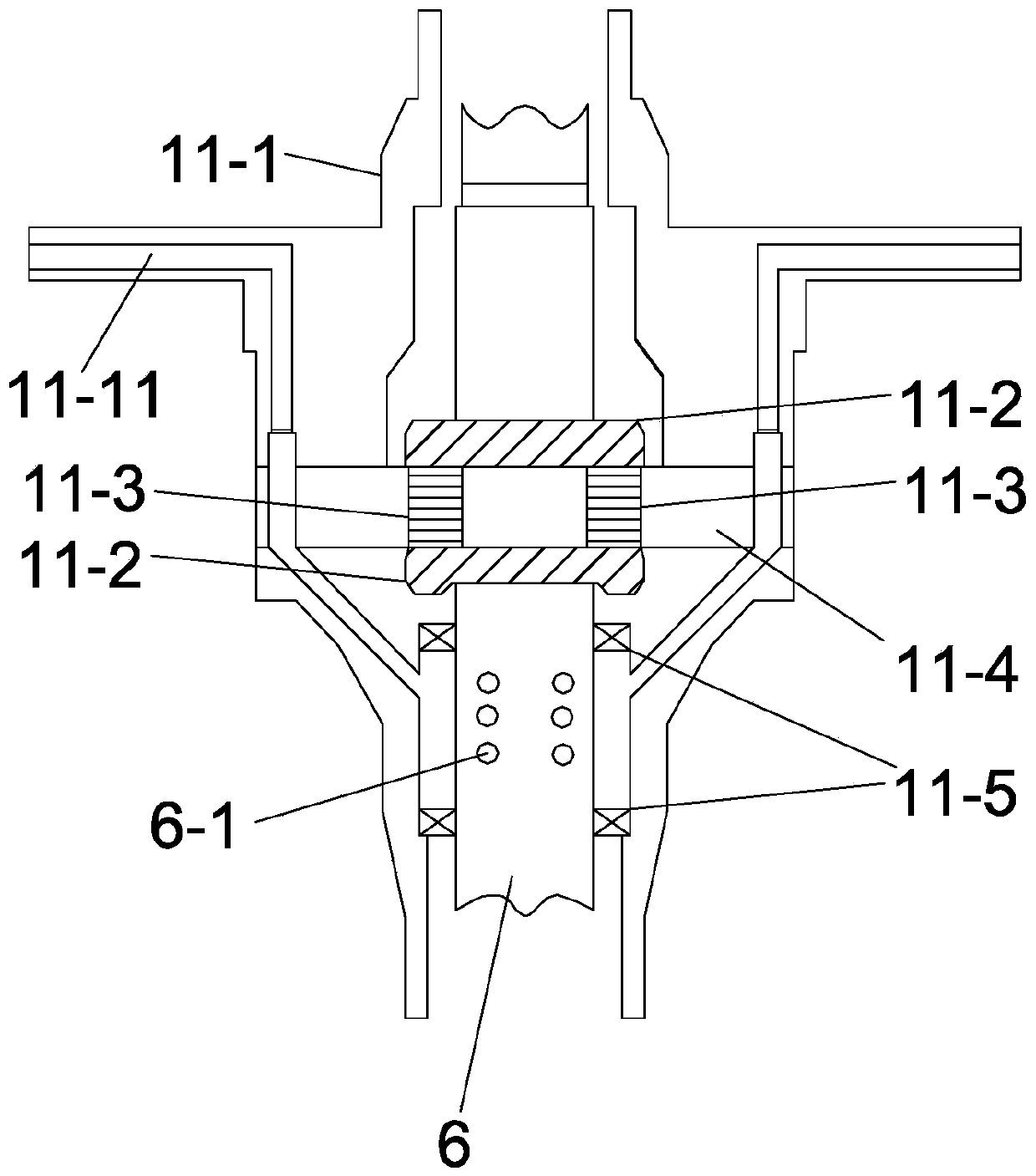

[0061] Such as figure 1 As shown, the mine dust removal system included in the present invention includes a primary dust removal device, a secondary dust removal device, a tertiary dust removal device, a sedimentation filter tank 13 and a water storage device 51;

[0062] The first-level dust removal device includes a first-level dust removal outer cylinder 1, an air intake cylinder 2 connected to the upper opening of the first-level dust removal outer cylinder 1, and a rotary dust removal mechanism arranged in the first-level dust removal outer cylinder 1. The air intake cylinder 2 An air intake grid 3 is provided at the entrance of the air inlet; the rotary dust removal mechanism includes a first-stage dust removal inner cylinder 4, a turbo fan 5 and a water mist injection mechanism arranged in the first-stage dust removal inner cylinder 4, and is used for the first-stage dust removal. The inner cylinder 4, the turbofan 5 and the water mist injection mechanism provide a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com