Compound noni fermentation method and compound noni enzyme

A technology of compound fermentation and noni fruit, applied in the field of food processing, can solve the problems of different taste quality, poor application effect, low solid content, etc., and achieve the effect of good taste, high solid content and easy absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

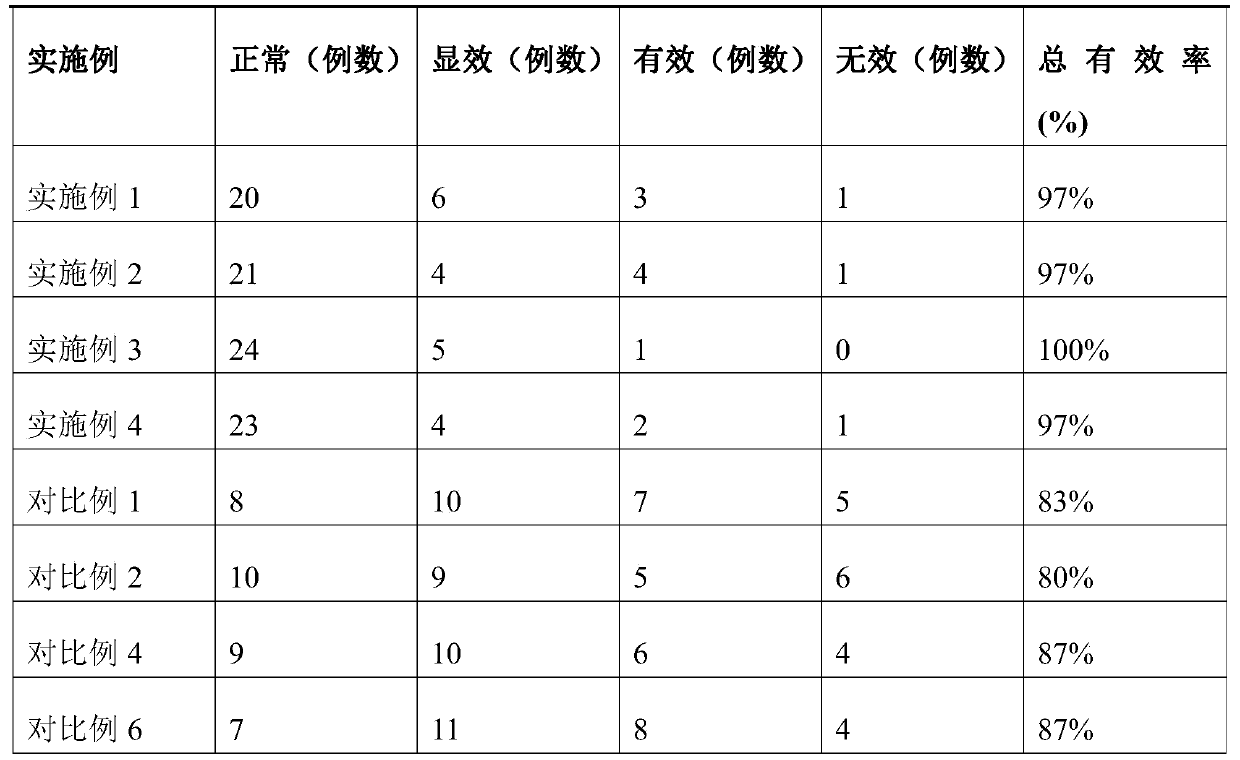

Examples

Embodiment 1

[0027] Embodiment 1-a kind of Noni fruit compound fermentation method comprises the steps:

[0028] (1) According to the ratio of parts by weight, take 85 parts of fresh noni fruit, 8 parts of dragon fruit, 5 parts of mulberry fruit, 2 parts of passion fruit and 8 parts of pineapple; after cleaning, put them in 0.3% dilute acetic acid solution Soak for 35 minutes;

[0029] (2) Squeeze the soaked fresh fruit, filter and separate to obtain compound fruit juice;

[0030] (3) After the compound fruit juice is treated with vacuum microwave and ultrasonic wave successively, wherein, the vacuum microwave treatment time is 1min, the ultrasonic treatment time is 8min, the empty microwave power is 200W, the ultrasonic power is 20W, add the compound enzyme in a 30°C constant temperature water bath Carry out enzymatic hydrolysis for 20h; the compound enzyme is formed by mixing cellulase, β-glucanase and bromelain in a mass ratio of 3:3:5; the amount of the compound enzyme added is 2% of ...

Embodiment 2

[0035] Embodiment 2--a kind of Noni fruit compound fermentation method, comprises the steps:

[0036] (1) According to the ratio of parts by weight, take 85 parts of fresh noni fruit, 8 parts of dragon fruit, 5 parts of mulberry fruit, 2 parts of passion fruit and 8 parts of pineapple; after cleaning, put them in 0.6% dilute acetic acid solution Soak for 30min;

[0037] (2) Squeeze the soaked fresh fruit, filter and separate to obtain compound fruit juice;

[0038] (3) After the compound fruit juice is processed by vacuum microwave and ultrasonic wave successively, wherein, the time of vacuum microwave treatment is 3min, the time of ultrasonic treatment is 6min, the power of vacuum microwave is 100W, and the power of ultrasonic wave is 25W. Carry out enzymatic hydrolysis for 12 hours; the compound enzyme is formed by mixing cellulase, β-glucanase and bromelain in a mass ratio of 8:8:10; the amount of compound enzyme added is 3% of the weight of the compound fruit juice, when ...

Embodiment 3

[0043] Embodiment 3--a kind of Noni fruit compound fermentation method, comprises the steps:

[0044] (1) According to the ratio of parts by weight, take 85 parts of fresh noni fruit, 8 parts of dragon fruit, 5 parts of mulberry fruit, 2 parts of passion fruit and 8 parts of pineapple; after cleaning, put them in 0.5% dilute acetic acid solution Soak for 32 minutes;

[0045] (2) Squeeze the soaked fresh fruit, filter and separate to obtain compound fruit juice;

[0046] (3) After the compound fruit juice is processed by vacuum microwave and ultrasonic wave successively, wherein, the time of vacuum microwave treatment is 2min, the time of ultrasonic treatment is 4min, the power of vacuum microwave is 150W, and the power of ultrasonic wave is 30W. Carry out enzymatic hydrolysis for 15 hours; the compound enzyme is formed by mixing cellulase, β-glucanase and bromelain in a mass ratio of 5:5:8; the amount of compound enzyme added is 2% of the weight of the compound fruit juice, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com