Efficiency threshing and cleaning device and harvester

A cleaning device, high-efficiency technology, applied in the direction of harvesters, threshing equipment, agricultural machinery and implements, etc., can solve the problem that the smoothness of material flow inside the threshing and cleaning device is not improved, and the distribution position and conveying capacity of the exudates are not satisfied. limited and other problems, to achieve the effect of uniform distribution of protruding materials, variable threshing strength, and strong ability to grab materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

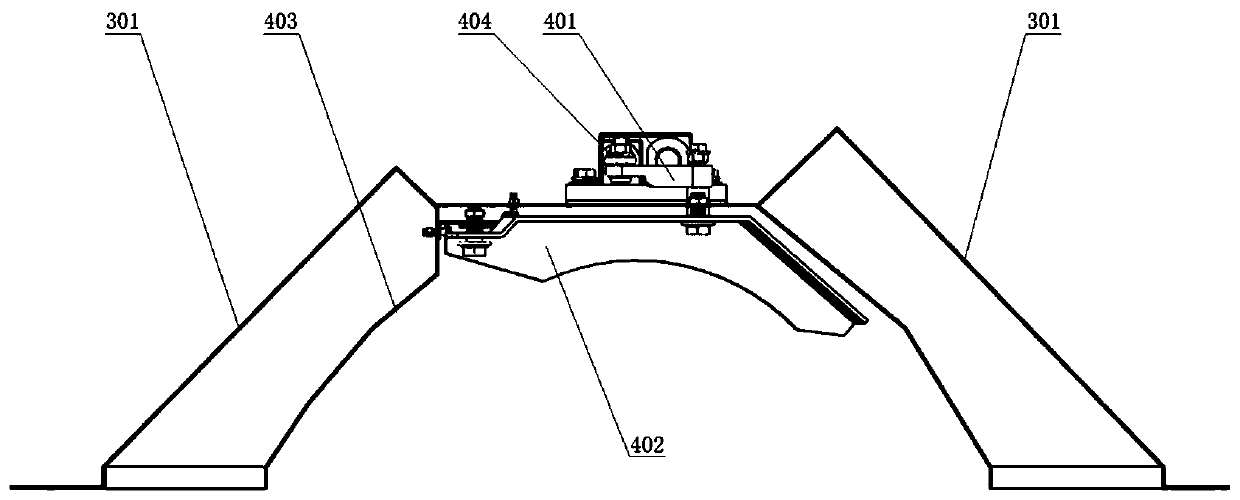

[0069] Such as figure 1 As shown, the high-efficiency threshing and cleaning device includes a tangential flow threshing and separation device 1, a screw feeding device 2, a longitudinal axial flow threshing and separation device 3, a variable diversion top cover 4, an extract distribution adjustment device 5, and an extract conveying device. Device 6, secondary miscellaneous auger 7, vibrating screen 8 and cleaning fan.

[0070] The screw feeding device 2 is located between the tangential flow threshing separation device 1 and the longitudinal axial flow threshing separation device 3. It has a strong ability to grab materials and prevents blockage and flow when the material transitions from a tangential flow state to an axial flow state. fluctuation. The variable deflector top cover 4 is located above the interior of the longitudinal axial flow threshing separation device 3, which increases the threshing separation area. The top cover deflector adjustment mechanism 401 and t...

Embodiment 2

[0090] A harvester, comprising the high-efficiency threshing and cleaning device described in Embodiment 1. Therefore, it has all the beneficial effects described in Embodiment 1, which will not be repeated here.

[0091] Preferably, the high-efficiency threshing and cleaning device of the present invention can be used in conjunction with a large feed volume combine harvester, and can meet the threshing and cleaning requirements of the combine harvester when the feed volume is 5kg / s-14kg / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com