Segment dislocation measuring device and method

A technology of misalignment measurement and measurement, which is applied in the field of segment misalignment measurement devices, can solve the problems that the arc surface of the segment and the feeler gauge cannot be closely fitted, the measurement is inconvenient, and manpower is consumed, etc., and the cost is low, Easy to obtain materials and work conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

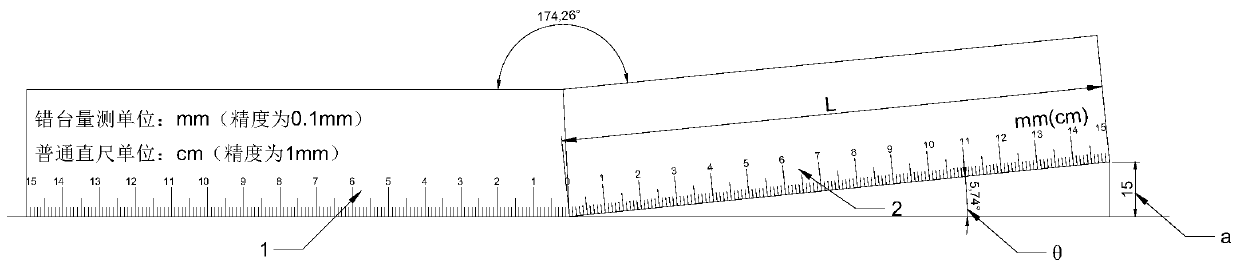

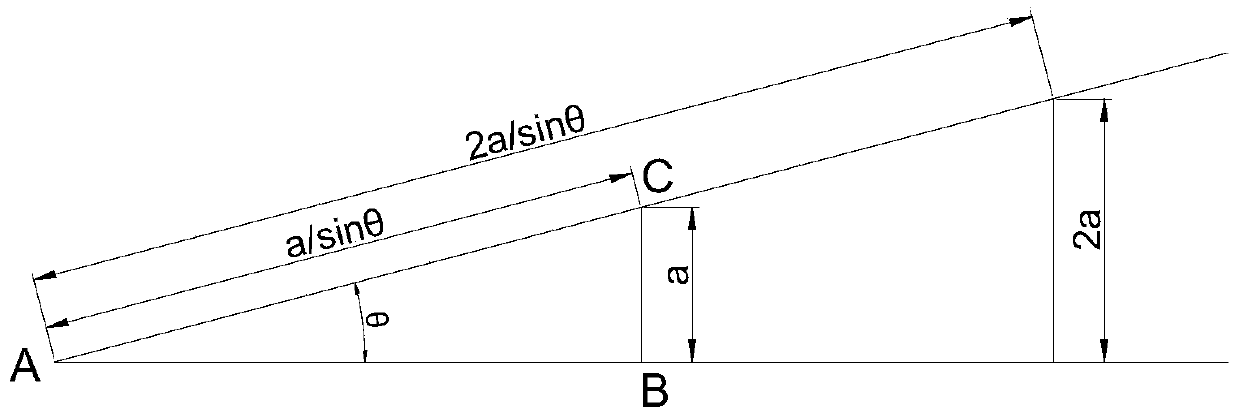

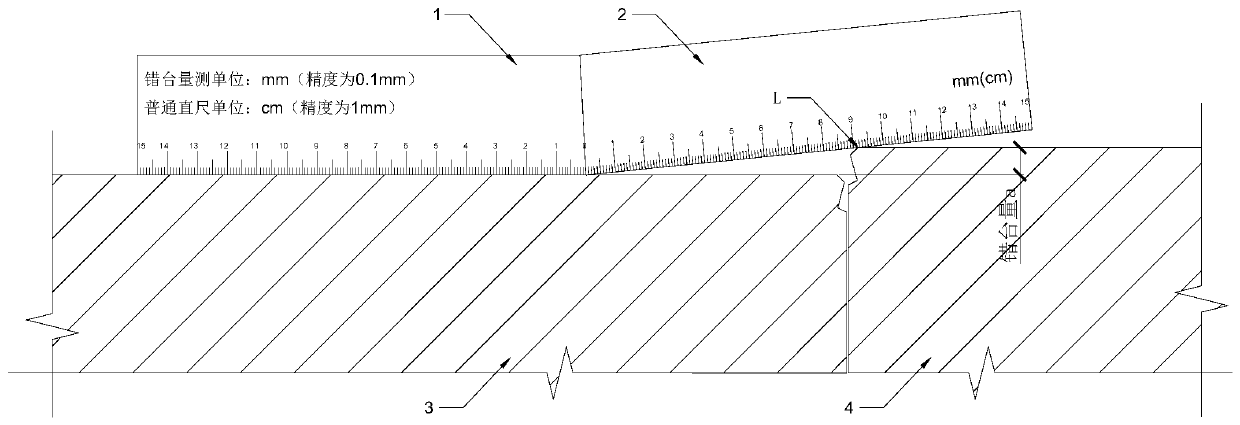

[0035] Take two rulers with a scale range of 0-15cm, an accuracy of 1mm, and a width of 35mm as the first measuring ruler 1 and the second measuring ruler 2, and connect them symmetrically at the 0 scale line to form an integrated structure, and the first The included angle between the measuring ruler 1 and the second measuring ruler 2 is 174.26°, that is, θ=5.74°, the misalignment a=L*sinθ=0.1L, and the measurement accuracy of the misalignment a is 0.1mm. Put the side with the scale line of the first measuring ruler 1 on the first segment 3, that is, the lower step segment of the staggered stage, and move along the direction of the first segment 3 to the second segment 4, that is, the raised segment of the staggered stage Move until the side with the scale line of the second measuring ruler 2 is just in contact with the second tube piece 4, and read the scale at the point of contact with the second tube piece 4 on the second measuring ruler 2 to be 9.1 cm, then The amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com