Temperature controlled switch and fuel cell gas in-out system with same

A temperature-controlled switch and temperature-dependent technology, applied in the direction of control valves, valve operation/release devices, valve details, etc., can solve the problems of battery stack damage, affecting the performance of MEA in fuel cell stacks, etc., to achieve wide application fields, structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Example: A temperature control switch and its application in a fuel cell cathode intake system

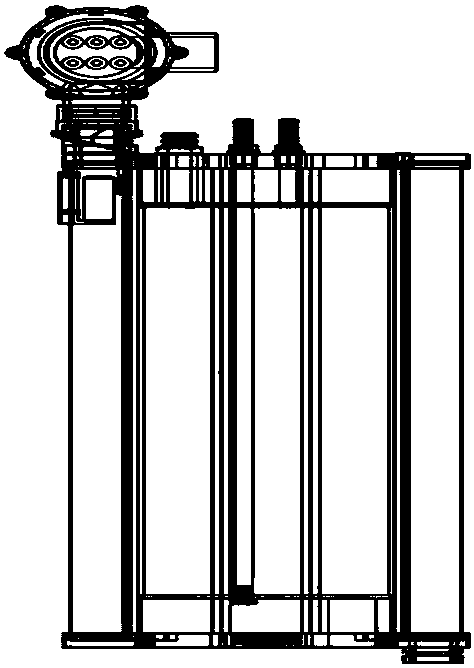

[0015] The fuel cell cathode air intake system of this embodiment includes an oxygen gas source, an air pump, a fuel cell cathode air inlet, and a gas pipeline connecting the above three in series; a temperature control switch is provided on the Inside the gas pipeline between the fuel cell cathode inlet and the gas pump.

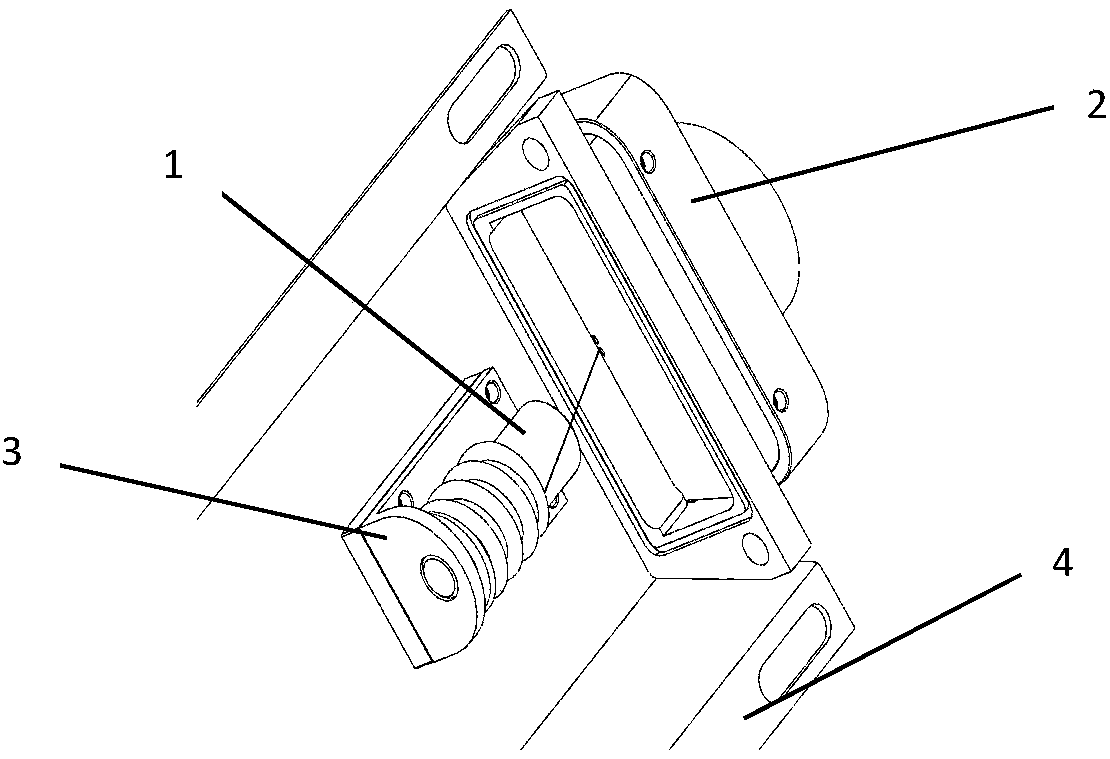

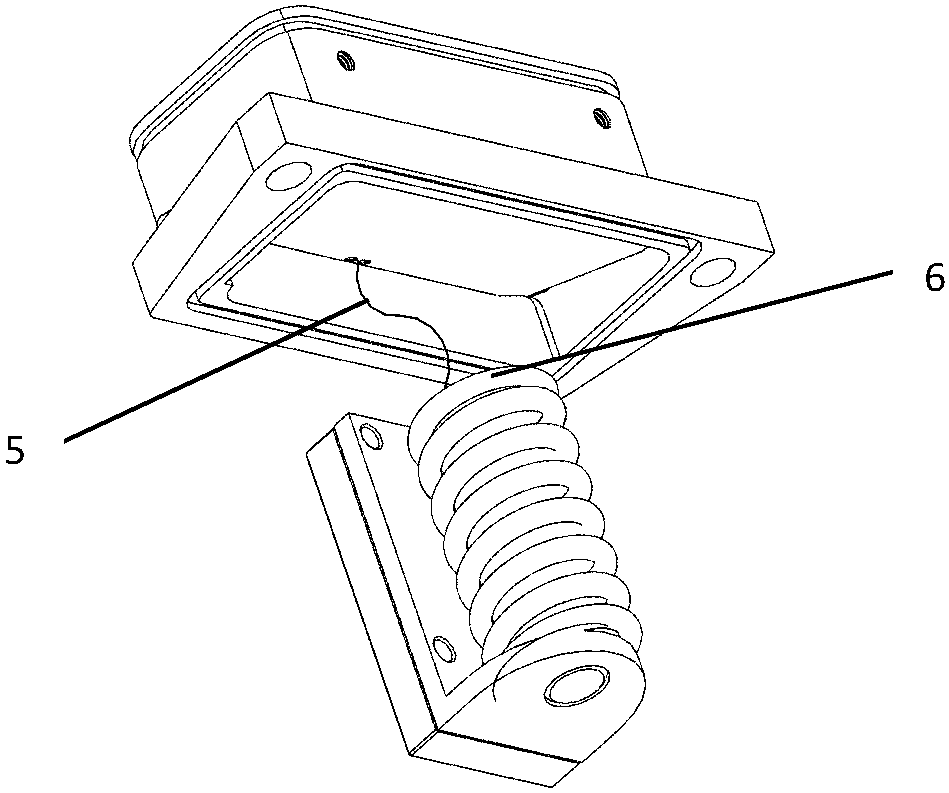

[0016] The temperature control switch includes a temperature control spring, a one-way valve, and a flexible connection chain connecting the two;

[0017] The one-way valve includes a valve core and a valve seat, and the valve core and the valve seat are connected by an asymmetric shaft; the flexible connecting chain and the one-way valve core are connected in an eccentric hinge form, so that the flexible connecting chain is connected with the valve core. The valve core forms a laborious lever;

[0018] The end of the temperature control spring away from the che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com