Planet gasket

A planetary and gasket technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the power split system - the big risk of the planetary row assembly, the wear resistance needs to be improved, the planetary pad The problem of easy wear and tear of the sheet can be solved, and the compactness can be improved, the surface wear resistance can be improved, and the safety can be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

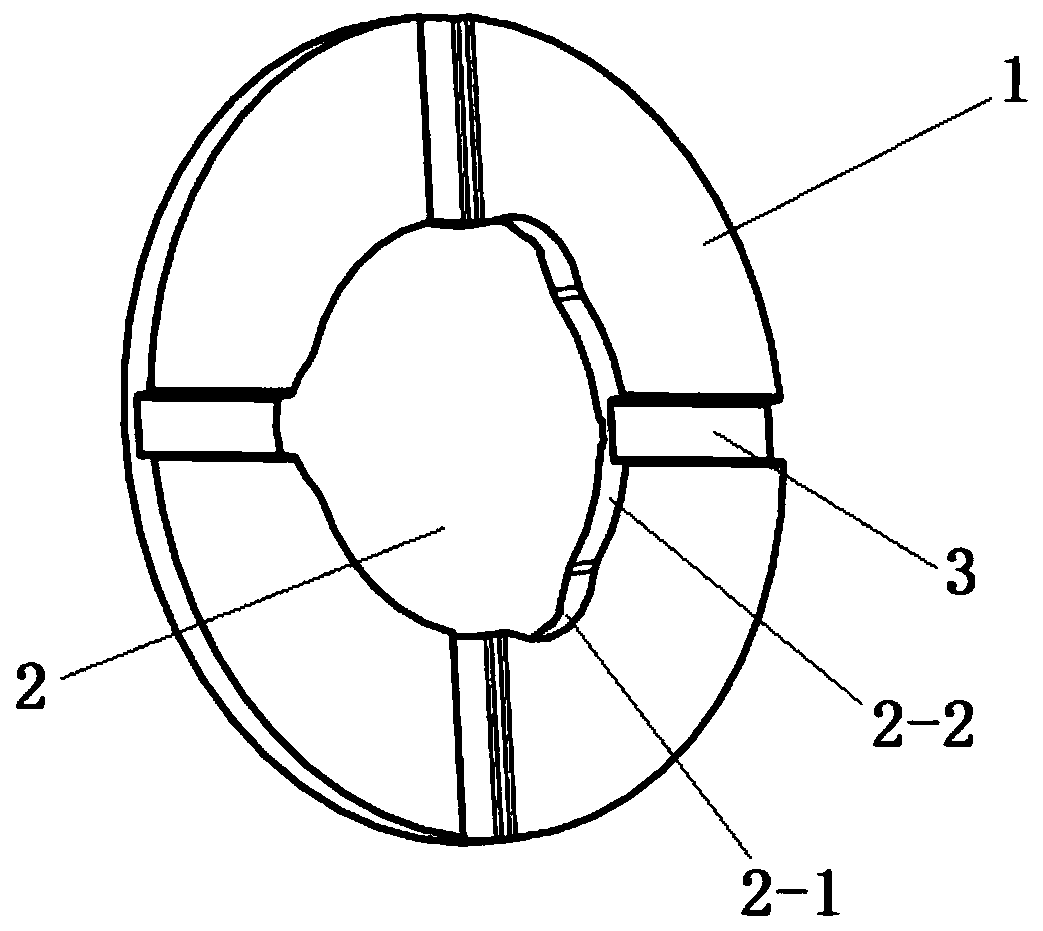

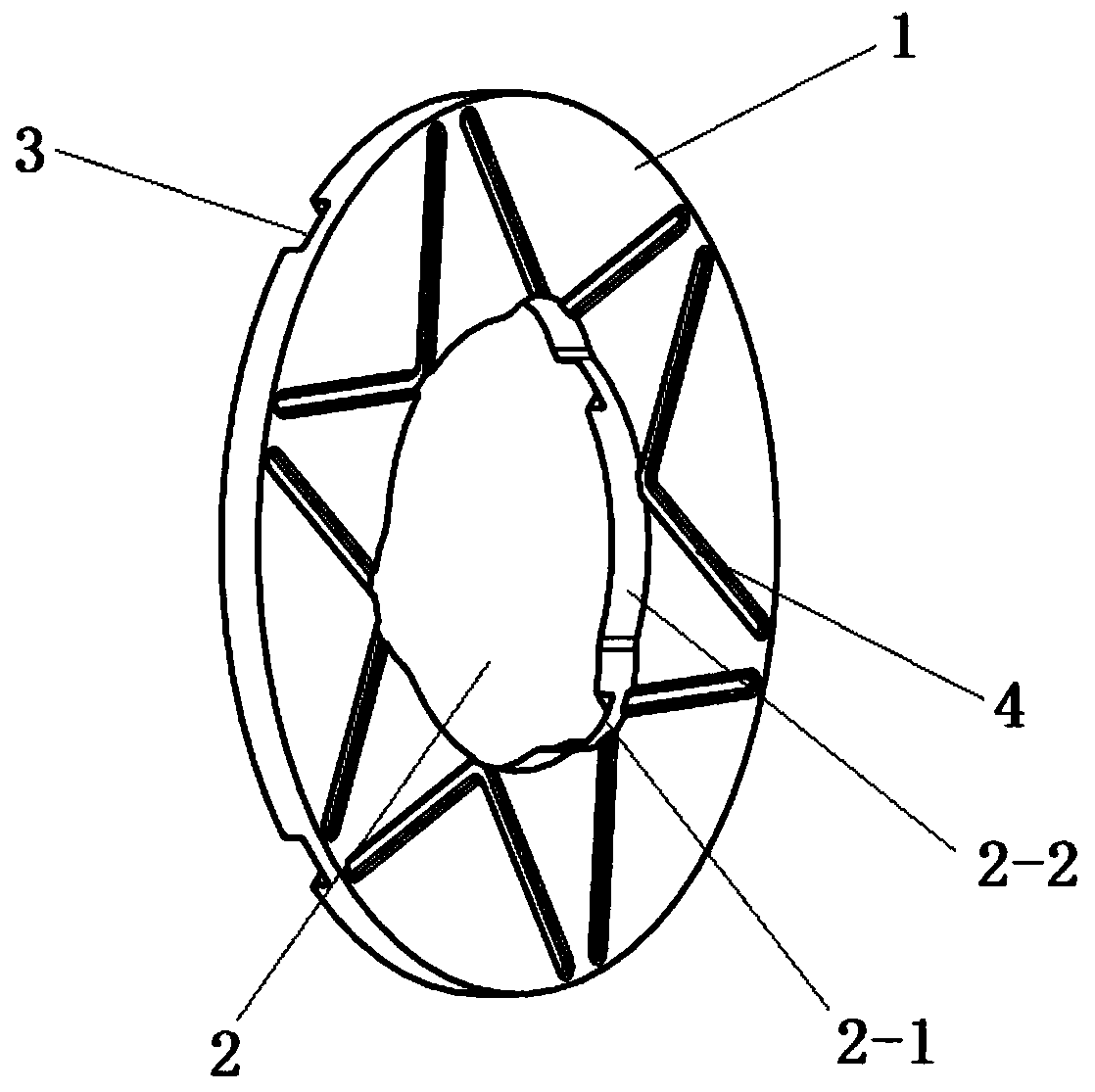

[0015] A planetary spacer, such as figure 1 , figure 2 As shown, including the main body 1, the thickness of the main body 1 is 2.6mm, the overall cross section of the main body 1 is circular, and a through hole 2 is opened in the middle of the main body 1, the overall cross section of the through hole 2 is approximately circular, and the through hole 2 consists of three sections The first circular arc segment 2-1 and the three second circular arc segments 2-2 are connected at intervals, the first circular arc segment 2-1 and the second circular arc segment 2-2 are concentric with the body 1, the first The length of the arc segment 2-1 is less than the length of the second arc segment 2-2, the diameter of the first arc segment 2-1 is greater than the diameter of the second arc segment 2-2, the through hole 2 and the corresponding planetary pin The shafts are matched, and the body 1 is provided with four first grooves 3 with a cross-shaped cross-section that are evenly distri...

Embodiment 2

[0018] A planetary gasket, its structure is similar to that of a planetary gasket in Example 1, the difference is that: the thickness of the body is 2.4mm, the number of the first groove is three, the first groove Evenly distributed along the circumferential direction, the width of the first groove is 2.8mm, the depth of the first groove is 1.1mm; the number of the second groove is five, the width of the second groove is 0.8mm, and the depth is 0.2mm , the V-shaped included angle is 100°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com