A spiral multi-space structure system

A technology of spiral rise and space structure, applied in special structures, building components, etc., can solve the problems of failing to reflect the overall charm of the spiral building structure, and achieve the effect of beautiful appearance, enhanced lateral rigidity, and overall load bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

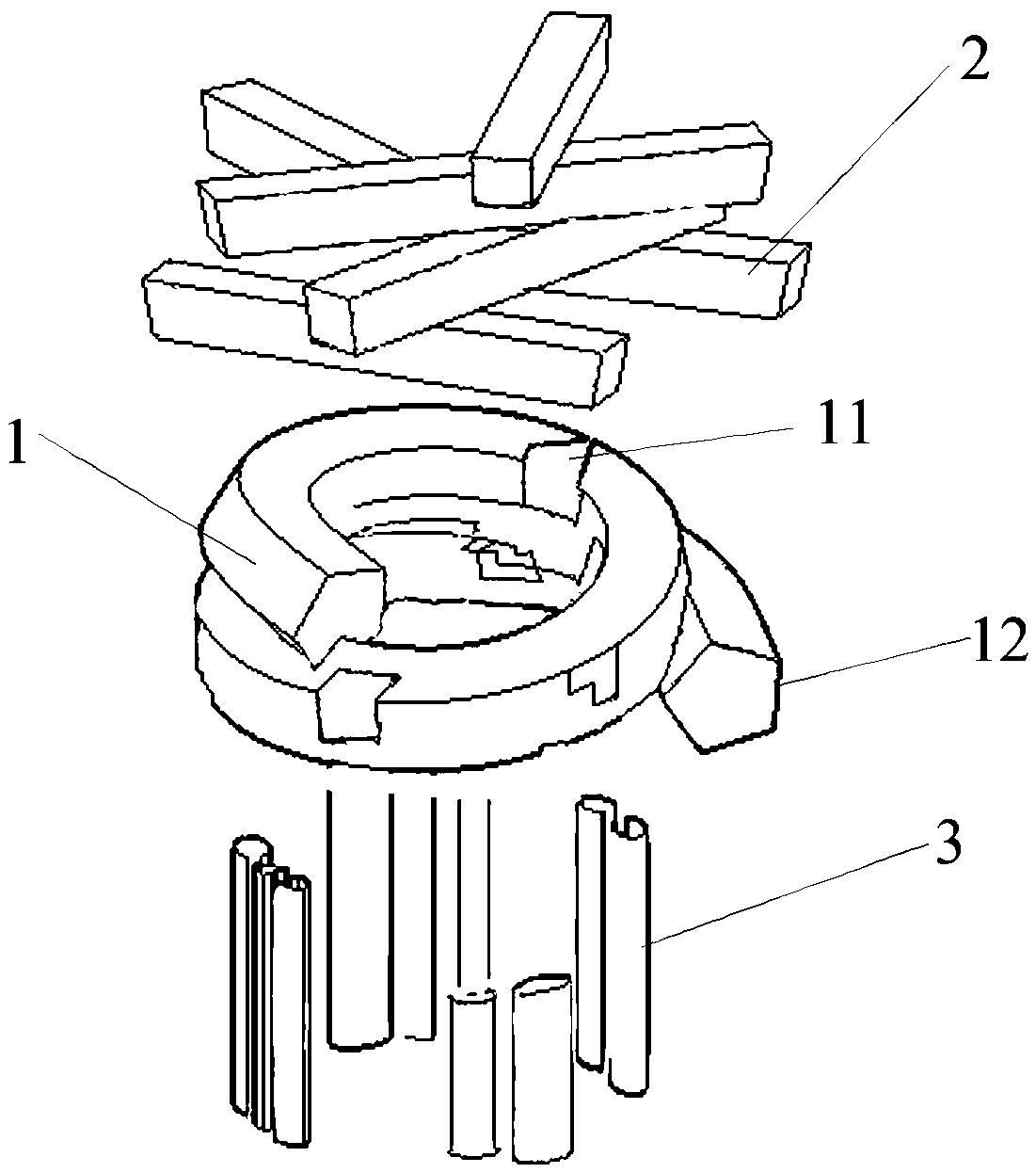

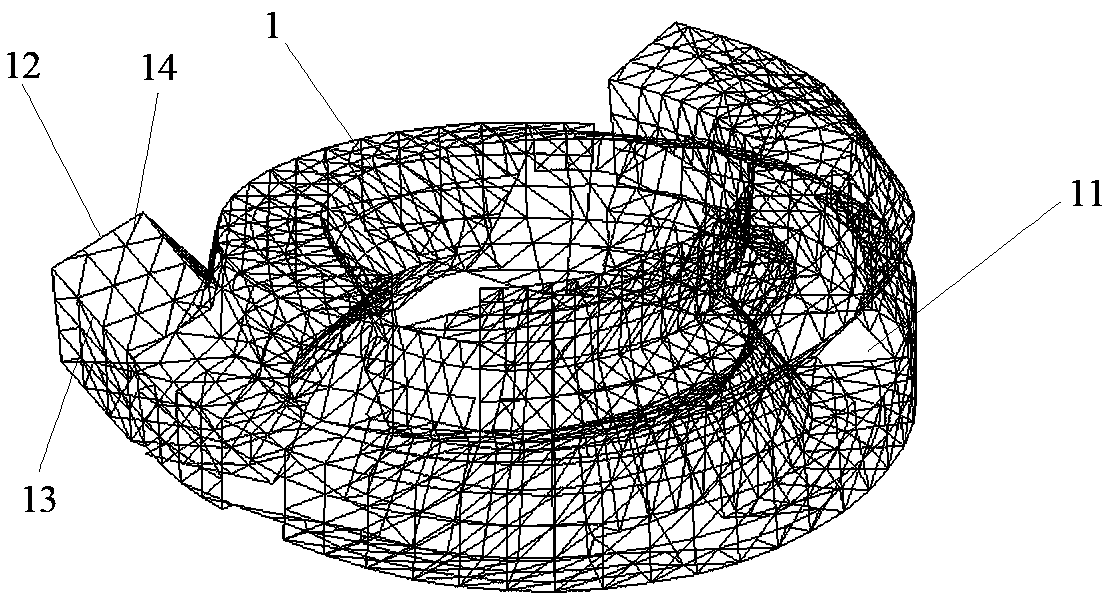

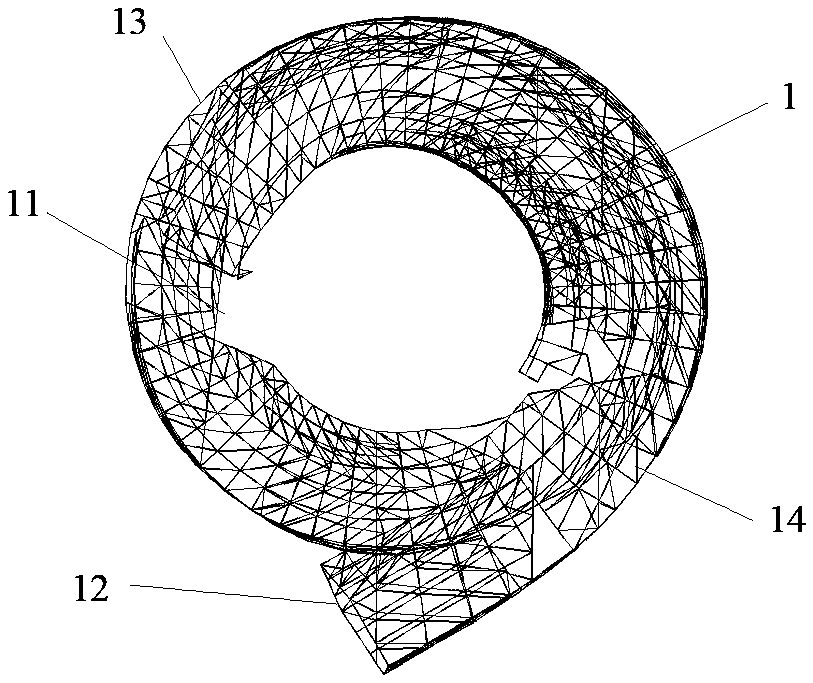

[0024] like figure 1 As shown, the three-dimensional schematic diagram of the partial decomposition of the spiral multi-space structure system, the external steel grid 1, the polygonal steel frame 2 and the core tube 3 are decomposed, the upper part of the schematic diagram is the polygonal steel frame 2, the middle part is the external steel grid 1, and the lower part is The core tube 3, wherein the external steel grid 1 is a spiral rising type, the polygonal steel frame 2 is welded on the connection port 11 inside the external steel grid 1, and the core tube 3 is connected between the polygonal steel frame 2 and the ground foundation; this embodiment The middle and outer steel grid 1 is a tubular space structure composed of pentagonal steel rods; the polygonal steel frame 2 is quadrilateral, including the polygonal steel frame 2 welded to the radial direction of the outer steel grid 1 and the 1 The circumferential polygonal steel frame 2, wherein the polygonal steel frame 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com