Deep foundation pit supporting system and construction method thereof

A technology of support system and deep foundation pit, applied in the field of rail transit, can solve the problems of economic loss, installation deviation, increased difficulty in hoisting, etc., and achieve the effects of avoiding collapse and deformation, reducing operation time and high equipment utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

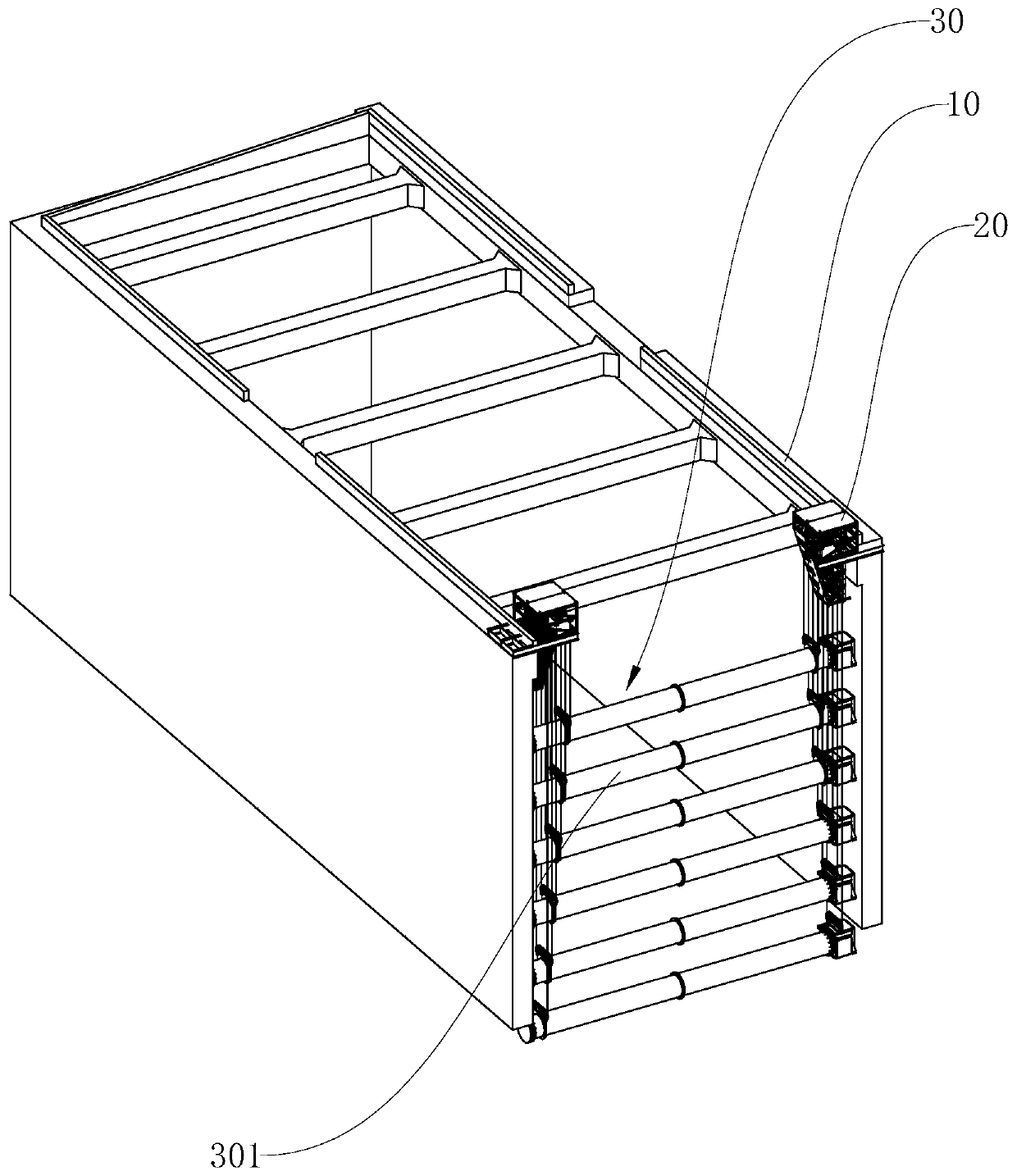

[0042] Embodiment 1: As shown in the figure, a deep foundation pit support system includes a crown beam 10 fixedly arranged on the top of the two walls of the foundation pit, and also includes two lifting brackets 20 and multiple sets of supporting devices 30, two lifting brackets 20 The brackets 20 are respectively fixed on the two crown beams 10, and each set of supporting devices 30 includes a support beam 301 and two lowering mechanisms 302, the supporting beam 301 is arranged horizontally between the two walls of the foundation pit, and the two lowering mechanisms 302 are respectively It is fixed on two lifting brackets 20 and is used to control the lifting of the support beam 301 in the foundation pit.

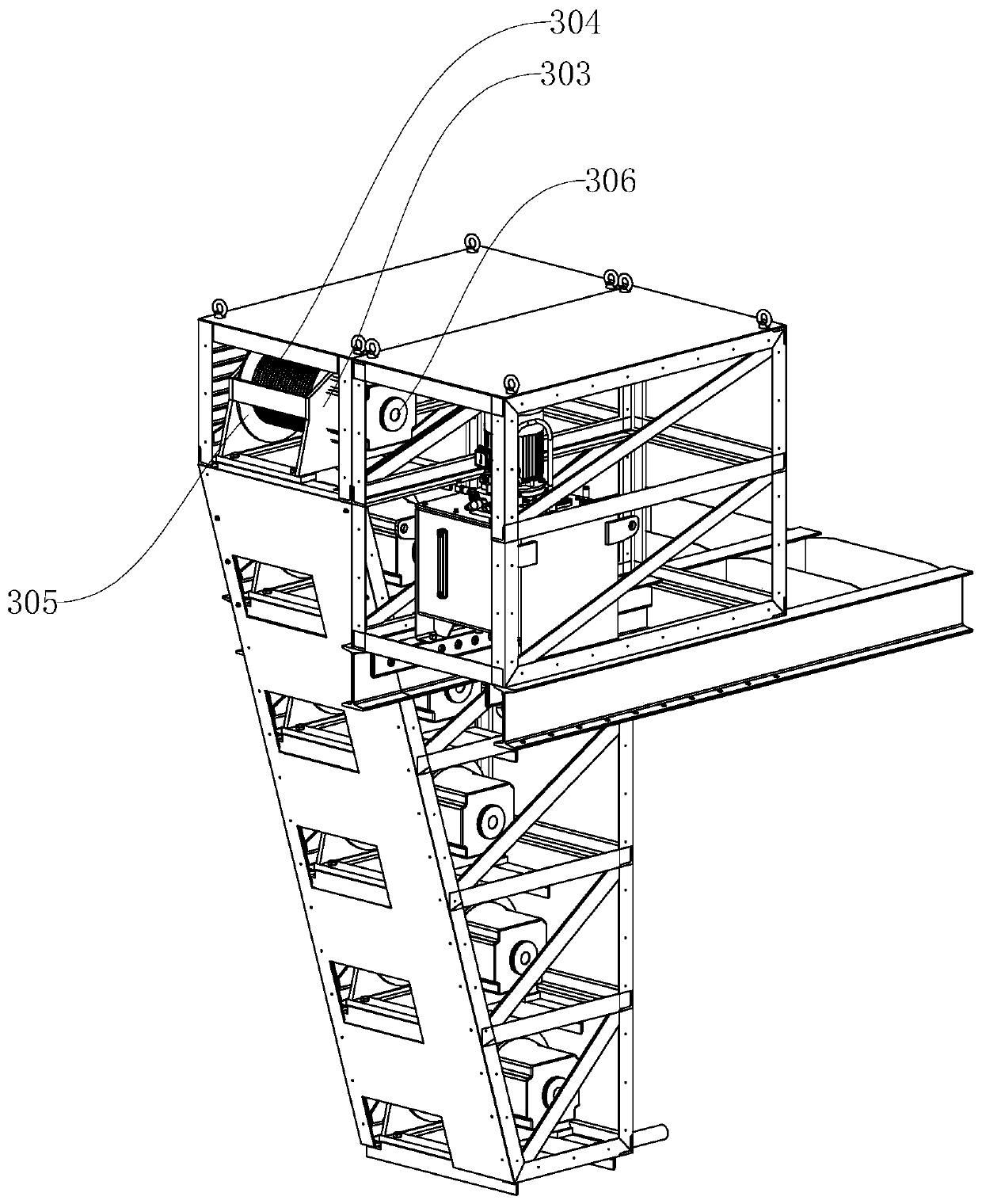

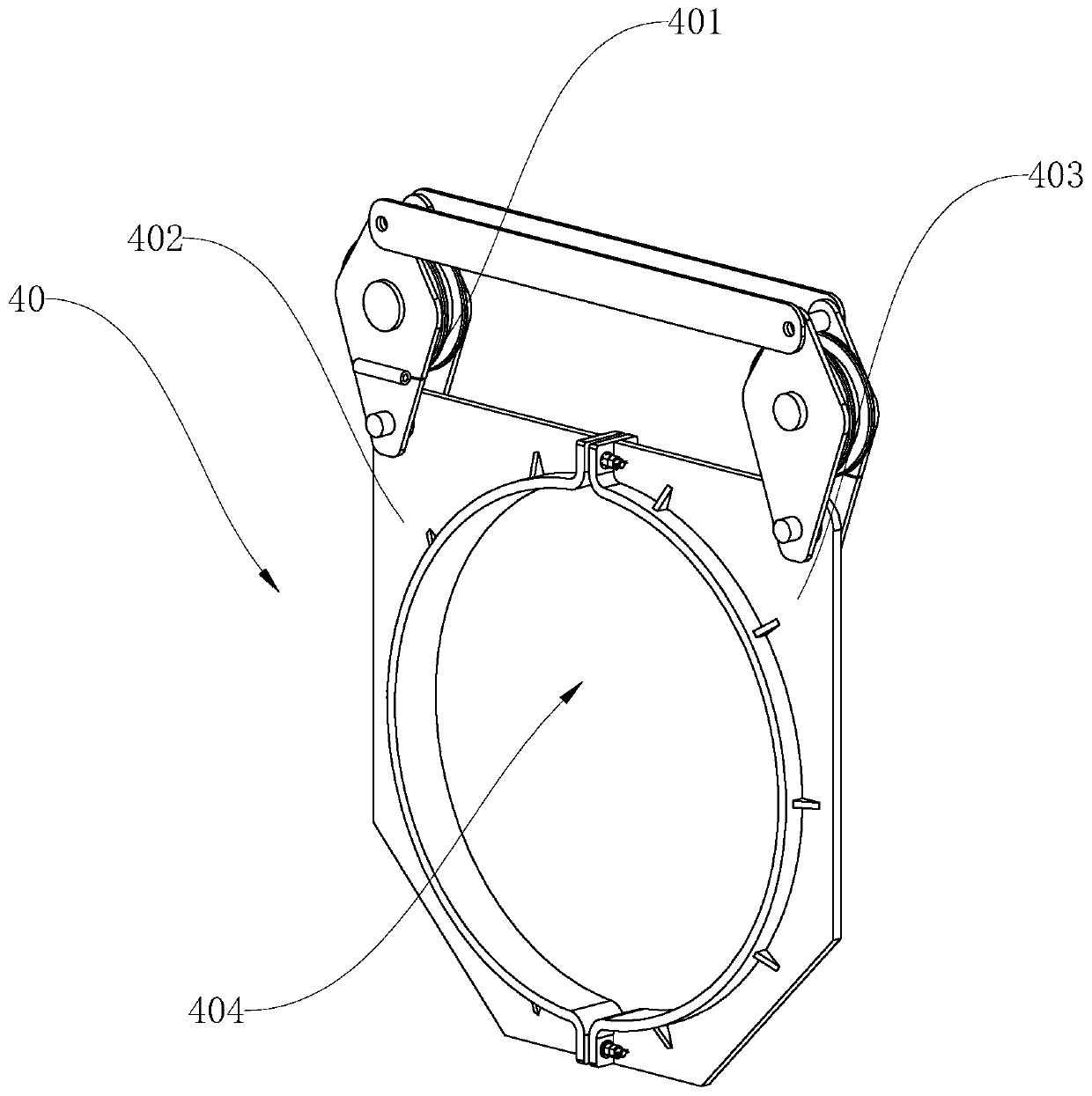

[0043] In this specific embodiment, each lowering mechanism 302 includes a winch support 303, a suspension cable 304, a reel 305, a hydraulic motor 306 for driving the reel 305 to rotate, and each end of the support beam 301 is equipped with a pre-installed hoop 40 , the...

Embodiment 2

[0048] Embodiment 2: As shown in the figure, a deep foundation pit support system includes a crown beam 10 fixedly arranged on the top of the two walls of the foundation pit, and also includes two lifting brackets 20 and multiple sets of supporting devices 30, two lifting brackets 20 The brackets 20 are respectively fixed on the two crown beams 10, and each set of supporting devices 30 includes a support beam 301 and two lowering mechanisms 302, the supporting beam 301 is arranged horizontally between the two walls of the foundation pit, and the two lowering mechanisms 302 are respectively It is fixed on two lifting brackets 20 and is used to control the lifting of the support beam 301 in the foundation pit.

[0049] In this specific embodiment, each lowering mechanism 302 includes a winch support 303, a suspension cable 304, a reel 305, a hydraulic motor 306 for driving the reel 305 to rotate, and each end of the support beam 301 is equipped with a pre-installed hoop 40 , the...

Embodiment 4

[0070] Embodiment 4: A method for foundation pit construction using a deep foundation pit support system, comprising the following steps:

[0071] S1: According to the design requirements, determine the total depth H of the excavated foundation pit, the total number n of support beams to be placed, the excavation depth of each layer of soil, and the support point of each layer of soil;

[0072] S2: Install crown beams on the top of the two walls of the foundation pit, and pour concrete support between the two crown beams. After pouring, install a lifting bracket and a lowering mechanism on each crown beam. After the installation is in place, carry out soil excavation;

[0073] S3: After the predetermined excavation depth of the first layer of soil is dug, stop excavation;

[0074] S4: hoisting the support beam into the excavated soil layer with a crane;

[0075] S5: Start the hydraulic motor, lower the suspension cable from the reel, make the suspension cable pass through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com