Production method of porous mesh steel strip reinforced composite tube

A technology for enhancing compounding and production methods, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of high cost, low efficiency, affecting the surface quality of the composite pipe, etc., and achieve the effect of large traction force and reliable traction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific examples.

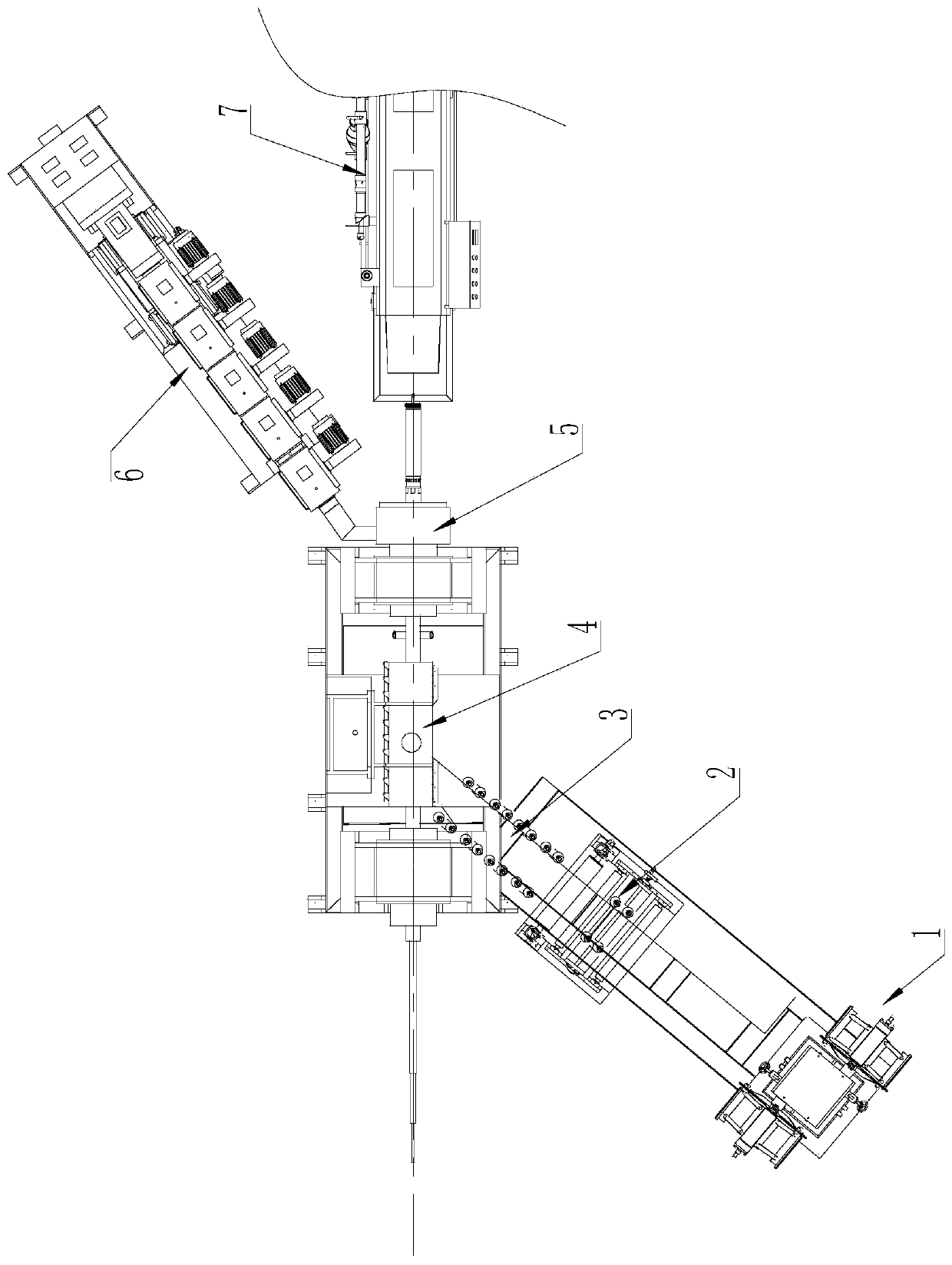

[0034] A method for producing a perforated steel strip reinforced composite pipe, comprising the following steps:

[0035] S1. Continuously unwind the perforated steel strip from the unwinder;

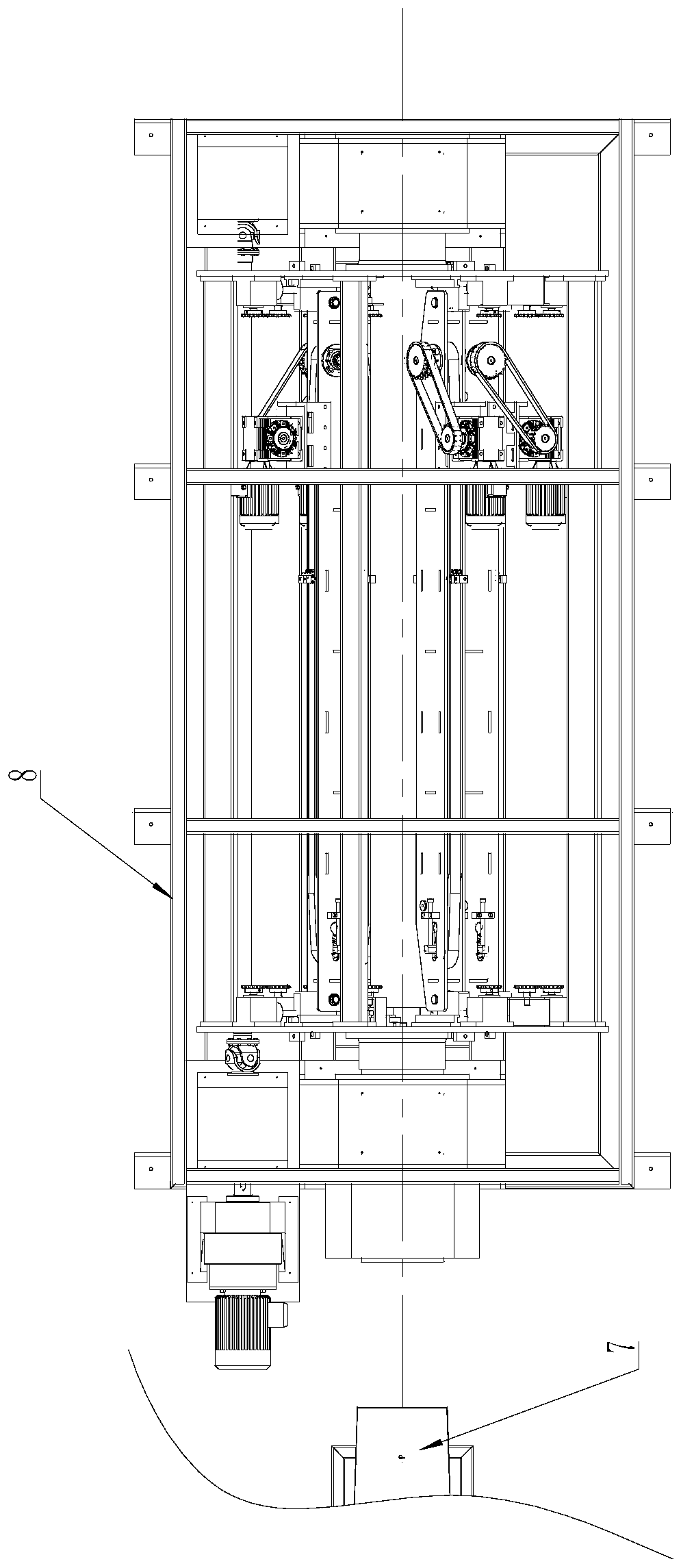

[0036] S2. The unrolled perforated steel strip is obliquely wound on the welding support cylinder of the rotary welding forming device and welded into a steel strip welded pipe;

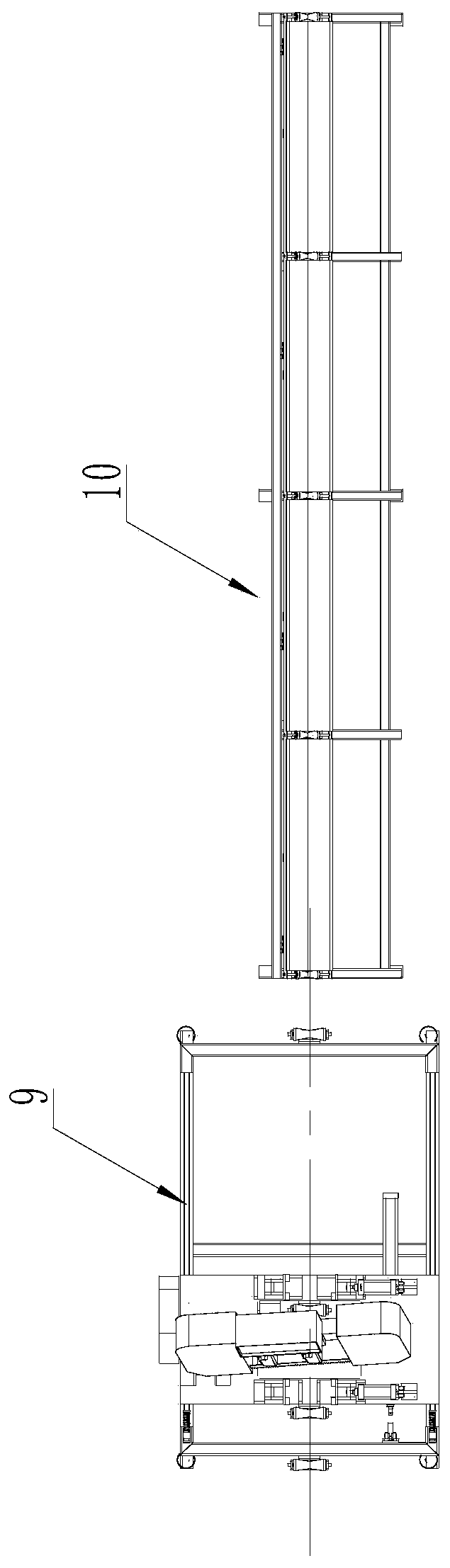

[0037] S3. The steel strip welded pipe rotates through the rotary composite molding die, and the plastic fluid extruded by the extruder enters the rotary composite molding mold to form an inner plastic layer and an outer plastic layer wrapping the steel strip welded pipe. The front end of the rotary composite molding mold is equipped with The steel strip welded pipe rotates in the same direction and at the same speed as the outer sizing die, and the compounded pipe passes through the inner hole of the outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com