Grinding wheel cleaning equipment

A technology for cleaning equipment and grinding wheels, applied to cleaning methods and appliances, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve problems such as difficult cleaning and troublesomeness, reduce the use of human resources, and have a simple structure , Easy to maintain and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

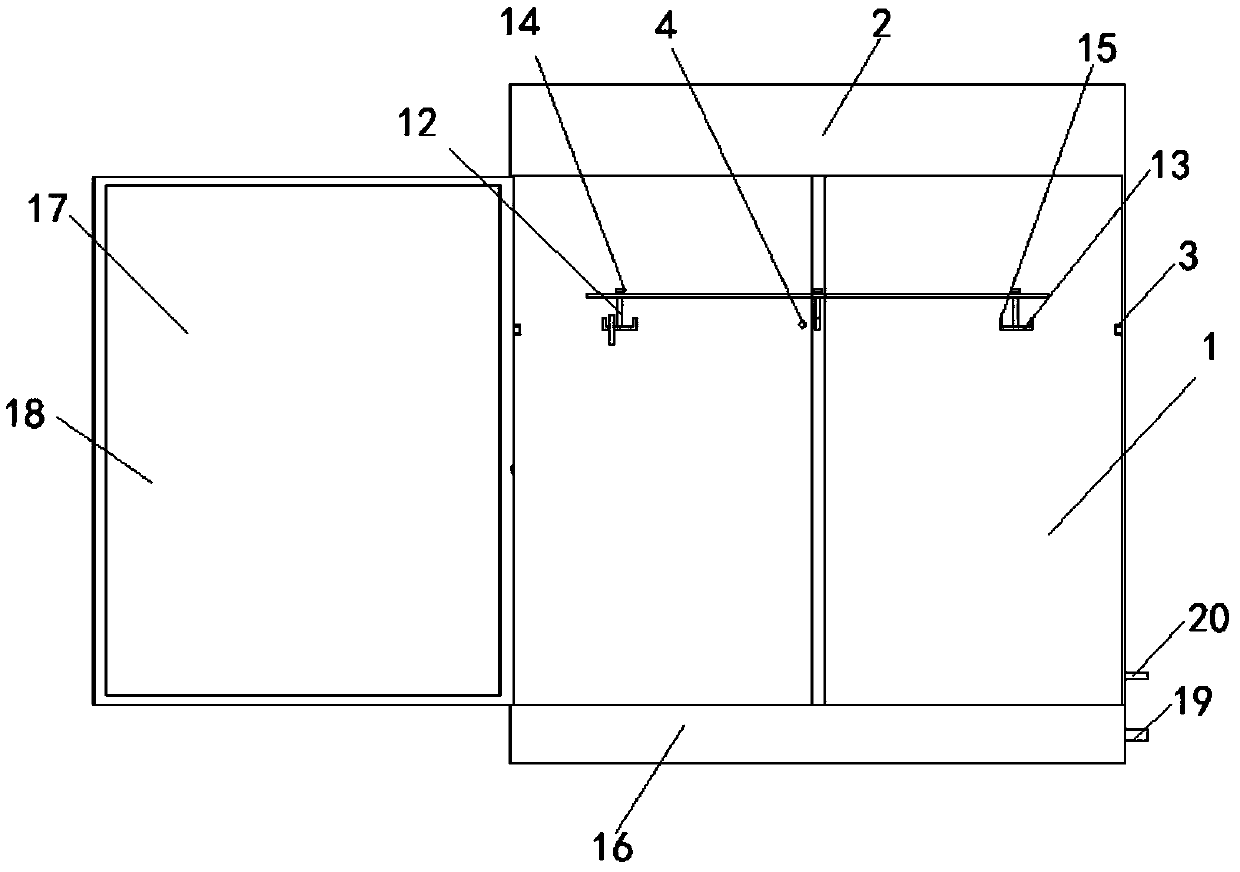

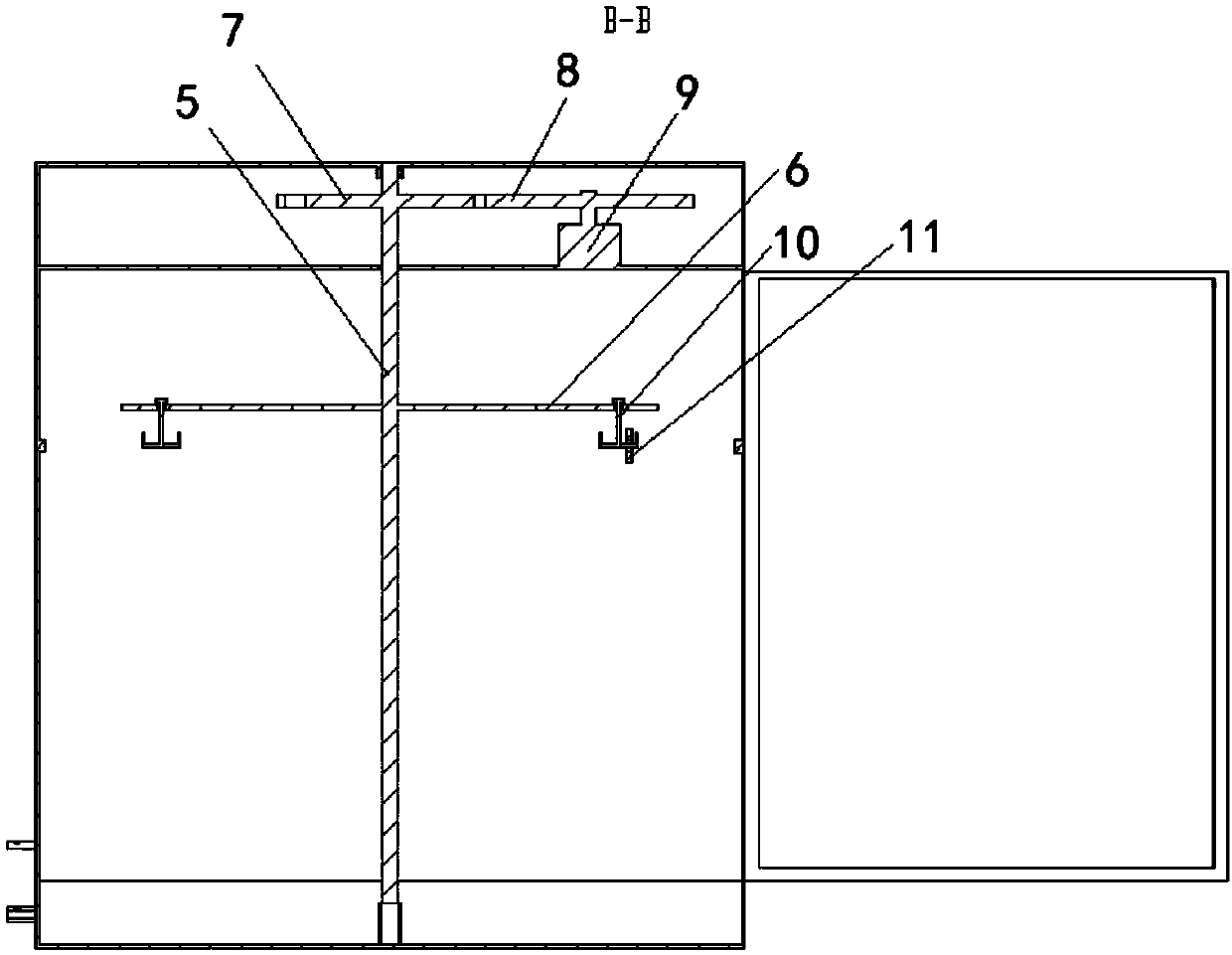

[0016] Embodiment 1: refer to Figure 1 to Figure 4 , a grinding wheel cleaning equipment, including a casing 1, a rotating device 2, a water spray device 3 and a drying device 4, a rotating device is arranged inside the casing, and the rotating device 2 includes a rotating shaft 5, a rotating frame 6, a first gear 7, a second Two gears 8 and motor 9, the rotating frame 6 is fixed on the rotating shaft 5, the first gear 7 is arranged on the upper end of the rotating shaft 5, the surface of the first gear 7 is evenly provided with twenty teeth, the first gear 7 and the second gear 8 is adapted and connected by rotation, the surface of the second gear 8 is uniformly provided with four teeth, the second gear 8 is provided on the motor rotation shaft, the inner surface of the shell 1 is provided with a water spray device 3 and a drying device 4, and a rotating frame 6 A grinding wheel clamping device 10 is arranged on it.

[0017] The water spray device 3 is arranged on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com